Electrostatically charged meltblown (MB) nonwoven fabrics are used as the filter medium in surgical masks and N95 particulate respirators. Filtration materials with high filtration efficiency are of great demand at present, as the public health, climate and ecosystems are at great risk of pollution from particulate matters (PM) and contagious microorganisms. Electrostatically charged nonwoven meltblown fibers can significantly improve the filtration efficiency of facemasks without adversely affecting the pressure drop. Therefore, electret filters are being widely used for air filtration, especially during this COVID-19 pandemic. However, it’s still quite challenging to retain the electrical charges at high temperatures and in wet atmospheres for an extended period.

Meltblown nonwoven fabric is commonly used as the filter media in surgical masks and N95 particulate respirators because of its high filtration efficiency (FE) against bacteria, virus and submicron particles. The output of the meltblown process is a microfiber (diameters ranging from 0.1 micron to 15 microns) that provides high filtration efficiencies at a low pressure drop through its high fiber surface area. The required filtration efficiency (FE) against bacteria, virus and submicron particles are achieved mainly by the electrostatic attraction of the particles on the fiber surface. The charges are embedded in the fibers that provides high breathability across the mask at a low pressure drop.

Fibrous materials are commonly used as the filter media for their high filtration efficiency (FE) and low air resistance. Electrostatic charging is employed to improve their filtration efficiency by 10 to 20 times by the electrostatic attraction of the particles without increasing its pressure drop.

There are mainly three techniques to charge the fibers or the fabrics. Different methods for electrostatic charging include: 1. Electrostatic spinning (ES), 2. Corona charging, and 3. Tribocharging. Electrostatic fiber spinning is basically a one-step process used to combine the charging of polymer with spinning of the fiber. Electrostatic fiber spinning produces nanofibers that offers very high filtration efficiency by mechanical filtration process. Electrospun polyethylene oxide fibers retain little amount of charge, however polycarbonate and and polyurethane contain very high amount of charge following an electrostatic spinning process. Corona charging is mainly used for charging monopolymer fiber or fiber blends or fabrics. Tribocharging method is mostly suitable for charging fibers with dissimilar electronegativity. If two dissimilar fibers are electrostatically charged using the tribocharging method, then it results in higher filtration efficiency than the corona-charged polypropylene fibers.

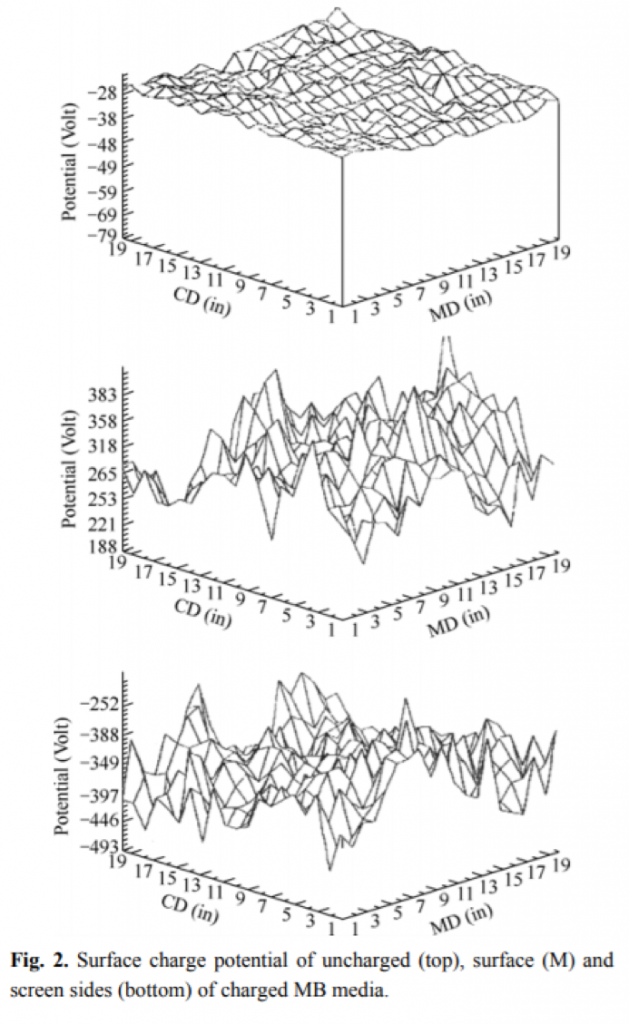

Dr. Peter Tsai, research faculty at the Joint Institute of Advanced Materials, The University of Tennessee, invented the electrostatic charging technology employed to nonwoven meltbown fabrics that has been widely used as the filter media for surgical and N95 masks. Dr. Peter Tsai’s research on electrostatic charging shows that a charged medium has at least 10 times higher filtration efficiency than an uncharged medium, meaning that one ply of charged fabric can have the effectiveness (FE) equal to 10 plies of the same uncharged filter media or fabric. Electrostatically charged nonwoven meltblown fabric also offers better air permeability compared to the uncharged one and this technology has significantly reduced the thickness of the filter media.

Basically, N95 respirator consists of four layers of polypropylene media—the outer layer, double-ply filtration layer and the inner layer that makes contact with the skin. The outer layer is usually made of spun-bond nonwoven fabrics that is intended to resist the moisture and contain the middle layer– double-ply filtration media. The inner layer is made of thermal-bond nonwoven fabrics. This layer usually offers low filtration efficiency and breathing resistance, and the primary purpose of this layer is to contain the middle layer along with the outer layer.

The required filtration efficiency in the N95 respirators and medical masks are mainly achieved by the double-ply middle filtration layer which is made of nonwoven melt-blown fabrics. This layer basically seals any gaps through which the particulate matter (PM) and microorganisms can enter and plays the major role in providing high filtration efficiency in N95 respirators and medical masks.

Two fundamental technologies are employed to produce this double-ply middle filtration layer: 1. Meltblowing and 2. Electrostatic charging. The meltblowing is mainly a nonwoven process that produces fabrics composed of microfibers and the electrostatic charging enhances the filtration efficiency by 10-20 times by embedding permanent charges (electrostatic attraction) in the fibers to make an electret filter media.

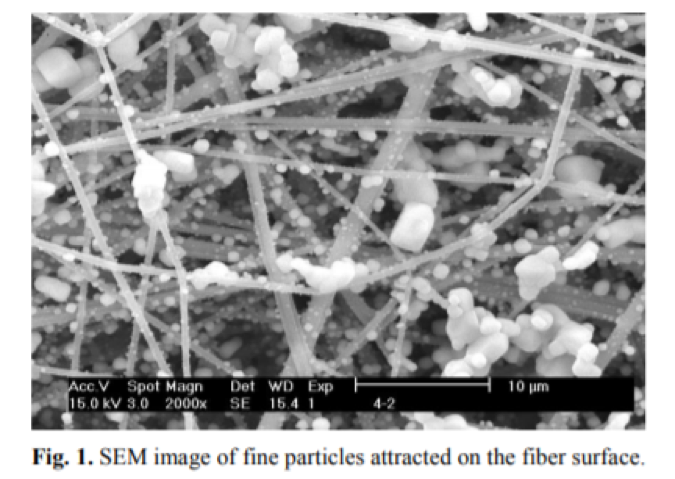

The filtration efficiency values of both face masks and N95 Respirators are mainly contributed by the middle layer of electrostatically charged meltblown fabric. According to standards of US medical masks specified in the ASTM F2100, there are three levels based on bacteria and submicron filtration efficiencies as well as the capability to stop blood penetration. The bacteria filtration efficiency is tested according to the ASTM F2101 standard using Staphylococcus aureus having the size in the range of 3 μm at a flow rate of 28.3 lpm (1 ft3 /min). The filtration efficiency of submicron particles is generally tested according to the ASTM F2299 standard using particulate latex spheres. The resistance to Penetration by the Synthetic Blood is tested based on ASTM F1862 standard and the “F” class in ASTM stands for the life-related testing standards.

Particle filtration mechanism, electrostatic charges, and electrostatic attraction mechanisms

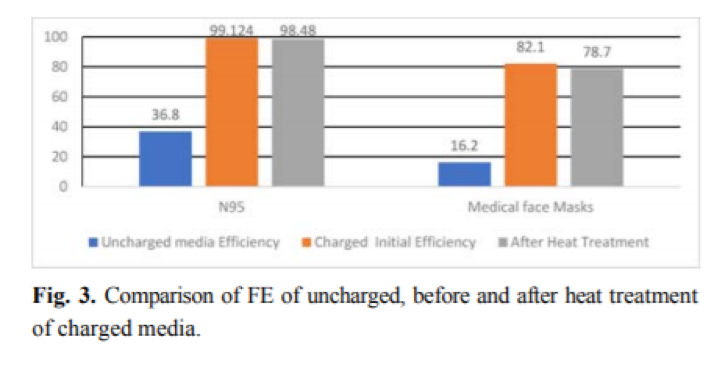

One way of the corona charging, as invented by Tsai, et. al., is a very common method to make electret for air filters including medical masks and N95 respirators. MB is a nonwoven process that makes microfibers having diameters in the range of 2 µm directly from polymer resin. For a given weight of nonwoven fabric, the finer the fiber diameter, the higher the total fiber surface area, and hence the better the FE. In contrast to liquid filtration mechanism, in which the filtration comes from the smaller pore size to block the larger particles, the efficacy of air filtration contributes from the attraction of particles by the fibers on their surface. Fig. 1 shows a 2,000× SEM image of fine particles attracted on the fiber surface, not the blocked particles by smaller pores. The pore size, which is the distance between two fibers, in a MB nonwoven fabric for face mask media, is around 20 µm. However, submicron particles are captured.

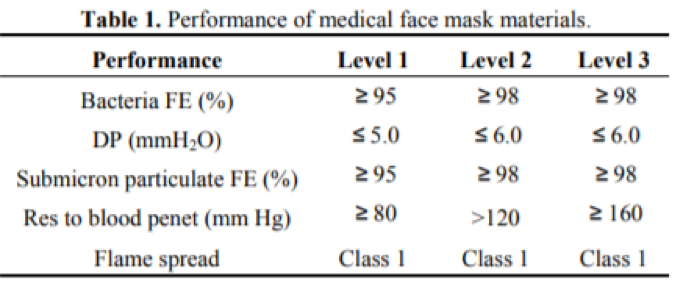

Both medical masks and N95 respirators are composed of an electrostatically charged MB fabric as the filtering piece. The increased FE of the MB fabric is tenfold by electrostatic charging compared with the uncharged one. In electrostatic charging, the charges are embedded deeply inside the fibers forming an electret that exhibits a quasi-permanent electrostatic field in contrast to a magnet that exhibits a permanent magnetic field. During the corona charging process, the high voltage electrical field ionizes the air, accelerates and forces the positive or negative charges into one side of a fiber while the opposite polarity of charges is induced into the other side of the fiber leading to a bipolar structure on the fabric as shown on the plots in Fig. 2. The uncharged fabric carries slightly negative charges from polymer processing by friction, positive on one side and negative on the other side of the charged fabric. In each plot, 400 data at the interval of one inch between two points were taken along the machine and the cross directions (MD and CD). MD is the fabric moving direction and CD is the direction across the width of the fabric. The unit of the surface charge potential is in volts as shown in the Z-axis.

Positive charges attract negative particles and vice versa by Coulombic force. The neutral fine particles can be polarized by the bipolar electric field between two fibers with opposite charges, becoming partially positive on one side and partially negative on the other side of the particle. The partially positive side is captured by negative charges and vice versa. This attraction force is image force by induction. Therefore, an electret is highly effective to capture bacteria, virus, fine particles, and smog, etc. with very high FE. As the electrostatic charges are embedded deep inside the fibers, they will not dissipate into the environment at a high humidity condition, nor in contact with water or metal materials, suggesting that the charges will retain when the respirator is splattered by water droplets in a rainy day. However, depending on washing methods, problems may arise due to the effect of mechanical forces on the fibrous material causing the material damage and charge decay. It is ineffective in disinfecting the virus by only water washing. According to CDC’s instruction, it requires to wash hands with soap water for at least 20 seconds to wash off the germs. The loss of charges by washing masks with soap water will be discussed in IV. 3. There is an unnoticeable charge decay of a face mask at ambient conditions such as at 25 °C for a lengthy period of time. The decay at elevated temperature such as at 70 °C for 24 hours as indicated in Fig. 3, simulating the charge decay at ambient conditions of shelf time for five years, is slow to guarantee a long-life storage time. Typically, the shelf time of respirators is 5-10 years defined by the manufacturers.