Description

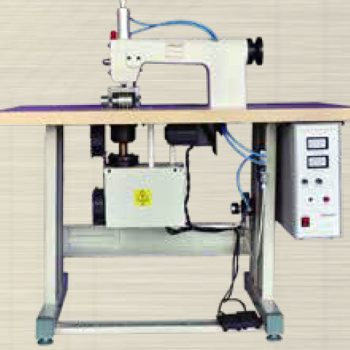

ULTRASONIC SEWING MACHINE

CARTON SET: WOODEN BOX

CTN SIZE: 1270, 540, 1200mm

QUANTITY/CTN: 1

CBM: 0.82

SINGLE MOTOR

OUTPUT POWER: 2500W

WPOWER INPUT: 220V

OUTPUT FREQUENCY: 20KHz

WORKING TEMPERATURE: -10-28C

WORKING SPEED: 0 TO 26M/MIN

EQUIPPED PATTERN MOULD: 0 TO 200mm

WEIGHT OF MACHINE: 95KG

DEVICE USAGE: (1) SEWING, (2) PATTERN CAR EDGE, (3) CUTTING, (4) SLITTING, (5) CUTTING HOLES, (6) PRESSING GRAPHICS, (7) FORMING, ETC. SEWING

MECHANICAL FEATURES:

1. THE FLOWER WHEEL WELDING HEAD OF ULTRASONIC EDGE MACHINE IS MADE OF SPECIAL ALLOY STEEL MATERIAL AND HAS THE CHARACTERISTICS OF WEAR RESISTANCE AND LONG SERVICE LIFE THROUGH SPECIAL HEAT TREATMENT PROCESS.

2. THE EDGING MACHINE CAN BE PROCESSED CONTINUOUSLY WITHOUT PREHEATING DURING OPERATION, WITH FAST SPEED, MASS PRODUCTION AND CORNER ROTATION. IT DOES NOT SMOKE OR SPARK DURING PROCESSING AND DOES NOT HARM THE EDGE OF CLOTH.

3. THE ULTRASONIC LACE MACHINE SEWING MACHINE IS EASY TO OPERATE AND UNDERSTAND, AND ORDINARY WORKERS CAN OPERATE ON THE MACHINE.

4. USE 20KHz LOW NOISE ULTRASONIC WAVE TO PREVENT NOISE INTERFERENCE.

5. ULTRASONIC EDGING MACHINE SUTURES ALL KINDS OF FABRICS DIRECTLY, AND AT THE SAME TIME MAKES EDGE CUTTING, HOLE CRACKING AND PRINTING TO MAKE THE PRODUCT FORM AT ONE TIME WITHOUT BURRS OR LOOSE HOLES.

6. ULTRASONIC EDGING MACHINE USES ULTRASONIC WAVE TO DIRECTLY WRAP ALL KINDS OF MATERIALS, PRESS ALL KINDS OF GRAPHICS, AND ADJUST POWER ACCORDING TO DIFFERENT FABRICS.

7. THE STRUCTURE OF THE WHOLE MACHINE IS FIRM AND DURABLE, ENSURING BETTER WELDING, CUTTING AND EMBOSSING EFFECT.

QUANTITY: 1