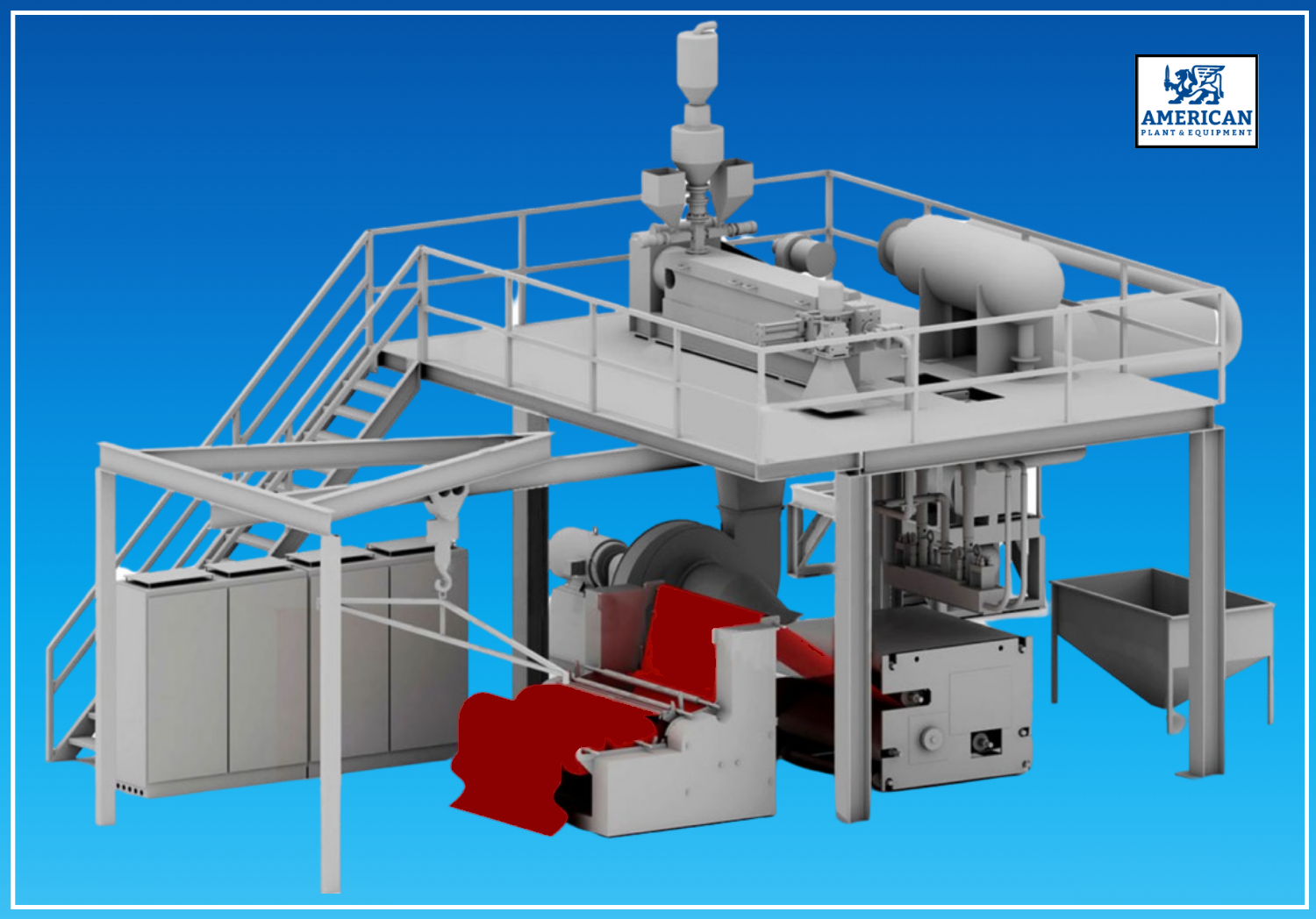

Description

MELT – SPRAY NON – WOVEN FABRIC IS ONE OF THE FASTEST DEVELOPING NON – WOVEN FABRICS AND IS KNOWN AS THE SHORTEST ONE – STEP POLYMER PRODUCTION PROCESS IN THE WORLD. ITS PRODUCTS WITH HIGH FILTERING EFFICIENCY, LOW RESISTANCE, SOFTNESS AND NETWORK CAN KNOT AND ADHESIVE AND SO ON MANY OBVIOUS ADVANTAGES OF ITSELF, THEREFORE, IS WIDELY USED IN MANY COUNTRIES, ITS MAIN USE IS IN EFFECT AND HIGH EFFICIENCY FILTRATION, INCLUDING AIR FILTRATION, ACID LIQUID FILTER FOOD HYGIENE, INDUSTRIAL DUST MASK MAKING, ALSO CAN MAKE HEALTH CARE PRODUCTS, INDUSTRIAL PRECISION WIPES, HEAT PRESERVATION MATERIAL, OIL ABSORPTION MATERIAL, BATTERY SEPARATOR, IMITATION LEATHER BASE CLOTH, AND SO ON. IN MANY RESPECTS ITS PERFORMANCE IS SUPERIOR TO THE SIMILAR PRODUCTS OF TRADITIONAL TEXTILES.WITH THE DEVELOPMENT OF POST – PROCESSING TECHNOLOGY, THE APPLICATION OF MELT – SPRAY NON – WOVEN FABRICS WILL BE MORE EXTENSIVE.

THE QUALITY AND ENERGY CONSUMPTION OF THE PRODUCTION LINES WITH VARIOUS WIDTHS ARE CLOSE TO THE ADVANCED LEVEL OF SIMILAR FOREIGN PRODUCTS.

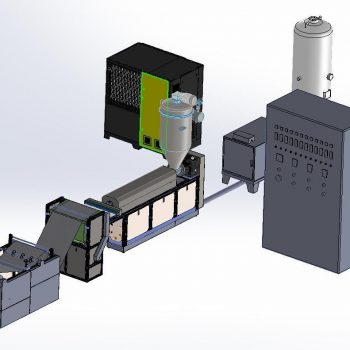

FEATURES:

• SPECIAL HANGER TYPE AND GAS EQUAL-PRESSURE SPINNING DIE HEAD WITH INDEPENDENT INTELLECTUAL PROPERTY RIGHTS ARE INCORPORATEDTO ENSURE UNIFORM MELT DISTRIBUTION

• THE AIR NOZZLE PRESSURE IS STABLE, THE AIR FLOW ON BOTH SIDES IS SYMMETRICAL AND THE AIR FLOW IN THE DIRECTION OF WIDTH IS UNIFORM

• EASY ADJUSTMENT OF AIR GAP WIDTH

• INCORPORATING THE SPECIALLY DESIGNED HOT GAS FLOW HEATING DEVICE, IT HAS GOOD HEATING EFFICIENCY AND EXCELLENT HEAT EXCHANGE EFFICIENCY AND ENERGY

• THE CONSUMPTION IS LOW

• THE RECEIVING DISTANCE CAN BE ADJUSTED, AND THE RECEIVING FORM (FLAT SCREEN RECEIVING AND DRUM RECEIVING) CAN BE EASILY REPLACED

• FIBER FINENESS AND CLOTH SURFACE UNIFORMITY

• STANDING – POLARIZATION TREATMENT MAKES MELTING SPRAY CLOTH HAVE GOOD FILTERING EFFECT

SPECIFICATIONS:

SERVICE CONDITIONS: 220 VOLTZ AND 50/60 HZ

PRODUCTION OF MELTING AND SPRAYING FILTERING MATERIALS: MASK FILTERING MATERIALS

USE MATERIAL: MFI= 1000 TO 1600 POLYPROPYLENE SLICING RAW MATERIALS

WIDTH OF PRODUCT SPECIFICATION: 1600 MM

WEIGHT RANGE: 10 TO 80 G / M2

EXTRUSION OUTPUT: 80 KG / H (THE PRODUCT IS CALCULATED ACCORDING TO 80 G / M2)

MAXIMUM MECHANICAL SPEED: 0 TO 50 M/MIN

FIBER FINENESS: 2000 TO 5000 MM

INSTALLED POWER: ABOUT 400 KW

OUTPUT: 25 G / M2 IS ABOUT 1 TON

EQUIPMENT SIZE: 16000 X 8000 X 6000 MM

FIVE COMMON APPLICATION FIELDS OF MELT-SPRAY NON-WOVEN FABRICS:

APPLICATION IN THE FIELD OF AIR PURIFICATION: USED IN AIR PURIFIERS AS SUB-HIGH – EFFICIENCY AND HIGH – EFFICIENCY AIR FILTER ELEMENTS AND FOR COARSE AND MEDIUM EFFICIENCY AIR FILTRATION WITH LARGE FLOW RATES.IT HAS THE ADVANTAGES OF LOW RESISTANCE, HIGH STRENGTH, EXCELLENT ACID AND ALKALINE RESISTANCE, CORROSION RESISTANCE, STABLE EFFICIENCY, LONG SERVICE LIFE AND LOW PRICE. THERE IS NO SHORT FLEECY PHENOMENON OF FILTER MATERIAL FALLING OFF IN THE PURIFIED GAS

THE APPLICATION IN THE FIELD OF MEDICAL AND HEALTH CARE: MADE OF MELT – BLOWN CLOTH DUST MOUTH BREATHING RESISTANCE IS SMALL, NOT SHORT, DUST EFFICIENCY OF 99%, WIDELY USED IN HOSPITALS, FOOD PROCESSING, MINING AND OTHER WORKPLACE TO DUST, PREVENT BACTERIA WITH ANTI – INFLAMMATORY ANALGESIC MEMBRANE MADE OF PRODUCT AFTER SPECIAL TREATMENT, PERMEABILITY IS GOOD, NON – TOXIC SIDE EFFECTS, EASY TO USE, AND SPUN – BONDED FABRIC OF SMS COMPOSITE PRODUCTS ARE WIDELY USED IN THE PRODUCTION OF SANITARY PRODUCTS SUCH AS SURGICAL CLOTHES

LIQUID FILTRATION MATERIALS AND BATTERY DIAPHRAGM: POLYPROPYLENE MELT – BLOWN FILTER CLOTH USED IN ACIDIC AND ALKALINE LIQUID, OIL, OIL HAS VERY EXCELLENT PERFORMANCE, SUCH AS THE BATTERY INDUSTRY AT HOME AND ABROAD HAS BEEN REGARDED AS A GOOD MEMBRANE MATERIAL, AND HAS BEEN WIDELY USED, NOT ONLY REDUCES THE COST OF BATTERY, SIMPLIFIES THE PROCESS AND GREATLY REDUCE THE WEIGHT AND VOLUME OF THE BATTERY

OIL – ABSORBING MATERIALS AND INDUSTRIAL RUBBING CLOTH: ALL KINDS OF OIL – ABSORBING MATERIALS MADE OF POLYPROPYLENE MELTING AND SPRAYING CLOTH, WITH OIL – ABSORBING CAPACITY UP TO 14 TO 15 TIMES OF ITS OWN WEIGHT, ARE WIDELY USED IN ENVIRONMENTAL PROTECTION ENGINEERING AND OIL – WATER SEPARATION ENGINEERING. IN ADDITION, THEY CAN BE USED AS CLEAN MATERIALS OF OIL AND DUST IN INDUSTRIAL PRODUCTION.THESE APPLICATIONS GIVE FULL PLAY TO THE PROPERTIES OF POLYPROPYLENE ITSELF AND THE ABSORBABILITY OF THE ULTRAFINE FIBER PRODUCED BY MELTING AND SPRAYING

THERMAL INSULATION MATERIALS: THE AVERAGE DIAMETER OF MOLTEN SHOTCRETE ULTRAFINE FIBER IS BETWEEN 500 AND 5000 MM, WITH LARGE SPECIFIC SURFACE AREA, AND A LARGE AMOUNT OF MICRO PORES ARE FORMED IN THE CLOTH WITH HIGH POROSITY.THIS STRUCTURE STORES A LARGE AMOUNT OF AIR, CAN EFFECTIVELY PREVENT HEAT LOSS, HAS EXCELLENT HEAT PRESERVATION, IS WIDELY USED IN THE PRODUCTION OF CLOTHING AND A VARIETY OF THERMAL INSULATION MATERIALS. SUCH AS LEATHER JACKET, SKI JACKET, COLD CLOTHING, COTTON VILLAGE CLOTH, WITH LIGHT, WARM, MOISTURE ABSORPTION, GOOD AIR PERMEABILITY, NO MILDEW AND OTHER ADVANTAGES

N95/ MEDICAL/CIVIL MASK MATERIAL M MELT-BLOWN NONWOVENS PRODUCT INTRODUCTION:

MASKS, WHOSE RAW MATERIALS ARE ALL POLYPROPYLENE (PP, REFERRED TO AS PP), MEDICAL SURGICAL MASKS ARE GENERALLY OF MULTI – LAYER STRUCTURE.

THE S IN THE MASK LAYER REPRESENTS THE SPUNBONDED FIBER. THE DIAMETER OF THE FIBER IS RELATIVELY THICK, ABOUT 20 MICRONS (NM), AND THE 2 LAYERS ARE MAINLY SPUNBONDED FIBERS

SUPPORTING THE WHOLE NON – WOVEN FABRIC STRUCTURE HAS NO OBVIOUS EFFECT ON THE BARRIER PROPERTY. THE MOST IMPORTANT LAYER INSIDE THE MASK IS THE BARRIER LAYER OR MOLTEN SPRAY LAYER (M). THE FIBER DIAMETER OF THE MOLTEN SPRAY LAYER IS RELATIVELY THIN, ABOUT 2 MICRONS (M), SO IT IS ONLY ONE TENTH OF THE DIAMETER OF THE SPUNBONDED LAYER, WHICH IS BENEFICIAL TO THE PREVENTION

PREVENTING BACTERIA AND BLOOD FROM ENTERING THE SPUNBONDED LAYER IS CRITICAL.FOR FIBERS SPUN TO THE BONDING LAYER, THE SPRAY LAYER M COMPARES THE SHAPE OF THE FIBERS TO THE HAIR, AS SHOWN BELOW, THE HAIR IS 1/3 OF THE DIAMETER, CLOSE TO THE SPINNING BONDING LAYER, AND 1/30 OF THE DIAMETER OF THE HAIR, CLOSE TO THE M FIBER DIAMETER. OF COURSE, FINER FIBERS ARE ALSO BEING DEVELOPED TO ENSURE BETTER ANTIBACTERIAL BARRIER PERFORMANCE

AS MENTIONED ABOVE, THE THINNER THE M LAYER, THE MORE IT CAN PREVENT THE ENTRY OF SMALL PARTICLES SUCH AS BACTERIA, SUCH AS N95, WHICH MEANS IT CAN BLOCK 95% UNDER NORMAL CONDITIONS OF SMALL PARTICLES (0.3 MICRONS), ACCORDING TO THE NATIONAL STANDARD GB/T 19083 FOR MEDICAL RESPIRATORS, IN GAS FLOW AT 85 L/MIN CONDITIONS

UNDER.THE N95 IS ACTUALLY A 5-LAYER MASK MADE OF POLYPROPYLENE NONWOVEN FABRIC SMMMS THAT FILTERS 95 PERCENT OF FINE PARTICLES