Description

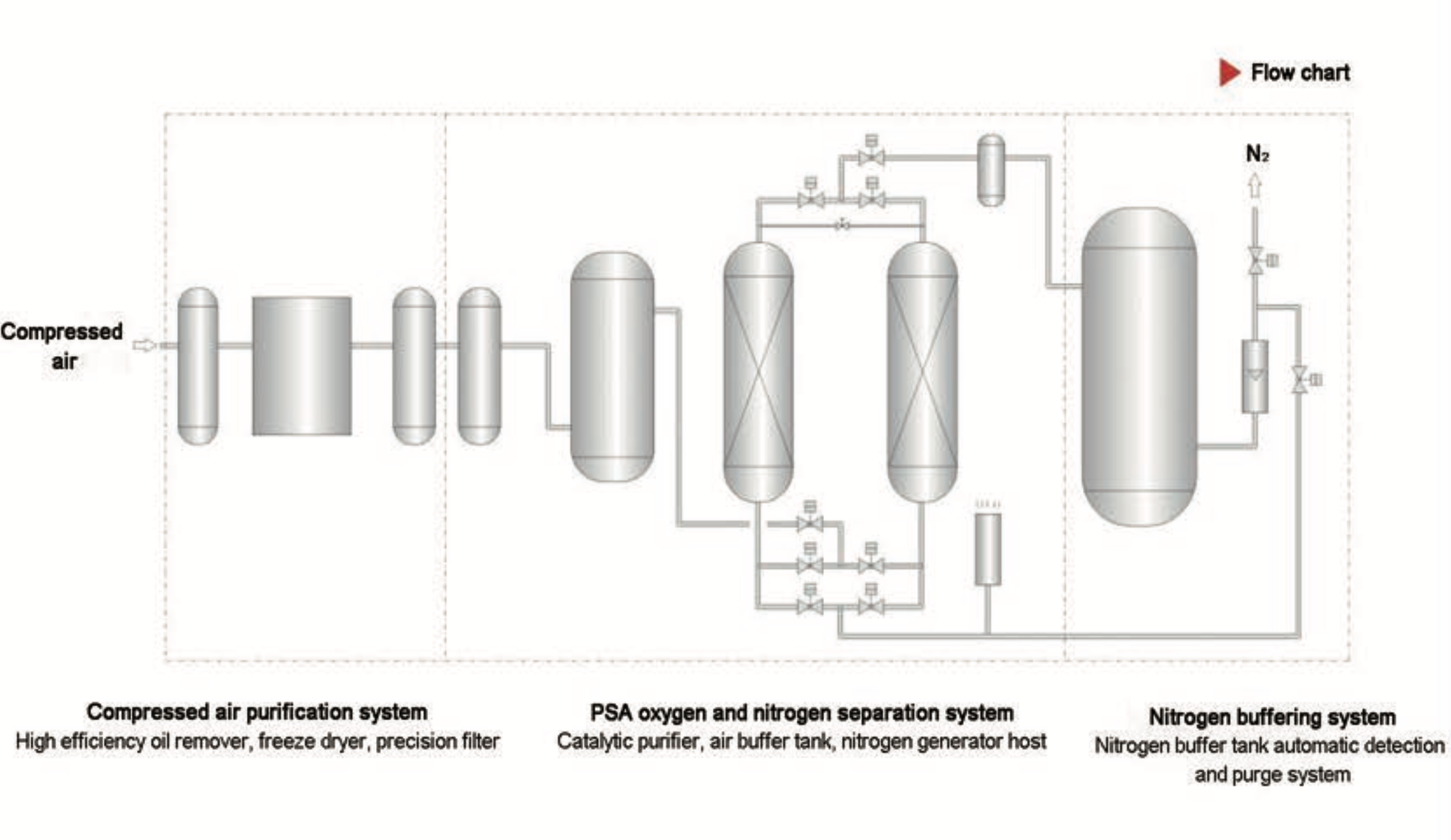

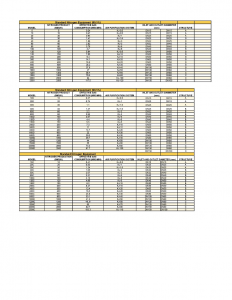

PSA NITROGEN ADSORPTION EQUIPMENT

WORKING PRINCIPLE:

UNDER A CERTAIN PRESSURE, THE DIFFUSION RATES OF OXYGEN AND NITROGEN IN THE AIR ON THE CARBON MOLECULAR SIEVE ARE GREATLY DIFFERENT. IN A SHORT TIME, OXYGEN MOLECULES ARE ADSORBED BY THE CARBON MOLECULAR SIEVE IN LARGE QUANTITIES, AND NITROGEN MOLECULES ARE ENRICHED IN THE GAS PHASE TO ACHIEVE OXYGEN AND NITROGEN SEPARATION.

SINCE THE ADSORPTION CAPACITY OF THE CARBON MOLECULAR SIEVE TO OXYGEN VARIES SIGNIFICANTLY WITH THE PRESSURE, THE OXYGEN MOLECULES ADSORBED BY THE CARBON MOLECULAR SIEVE CAN BE DESORBED WHEN THE PRESSURE IS REDUCED, SO THAT THE CARBON MOLECULAR SIEVE CAN BE REGENERATED AND REUSED.

TWO ADSORPTION TOWER PROCESSES WERE USED, ONE TOWER FOR NITROGEN PRODUCTION, THE OTHER TOWER FOR DESORPTION AND REGENERATION, AND THE CYCLE ALTERNATED TO CONTINUOUSLY PRODUCE HIGH-QUALITY NITROGEN.

TECHNICAL CHARACTERISTICS:

1. LOW ENERGY CONSUMPTION, STRONG ADAPTABILITY, FAST GAS PRODUCTION, EASY TO ADJUST THE PURITY.

2. PERFECT PROCESS DESIGN, OPTIMAL USE EFFECT.

3. MODULAR STRUCTURE DESIGN, SAVING FLOOR SPACE.

4. SIMPLE OPERATION, STABLE PERFORMANCE, HIGH DEGREE OF AUTOMATION, CAN ACHIEVE UNMANNED OPERATION.

5. REASONABLE INTERNAL COMPONENTS, UNIFORM AIRFLOW DISTRIBUTION, REDUCES THE IMPACT OF HIGH-SPEED AIRFLOW.

6. UNIQUE PROTECTION MEASURES OF CARBON MOLECULAR SIEVE, EXTEND THE SERVICE LIFE OF CARBON MOLECULAR SIEVE.

7. THE USE OF FAMOUS BRAND KEY COMPONENTS IS AN EFFECTIVE GUARANTEE OF EQUIPMENT QUALITY.

8. THE NATIONAL PATENT TECHNOLOGY OF AUTOMATIC AIR VENT DEVICE, TO ENSURE THE QUALITY OF FINISHED NITROGEN.

9. WITH A VARIETY OF FAULT DIAGNOSIS, ALARM AND AUTOMATIC PROCESSING FUNCTIONS.

10. OPTIONAL TOUCH SCREEN DISPLAY, DEW POINT DETECTION, ENERGY SAVING CONTROL, DCS COMMUNICATION, ETC.

TECHNICAL INDICATIONS:

NITROGEN PRODUCTION: 5 TO 3000NM3/H

PURITY OF NITROGEN: 95% TO 99.999%

NITROGEN PRESSURE: 0.1 TO 0.8MPA (ADJUSTABLE)

DEW POINT: -40OC OR -60OC

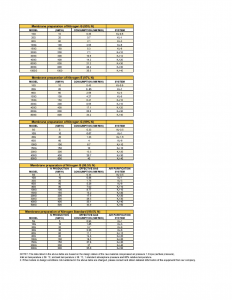

TECHNICAL PARAMETERS:

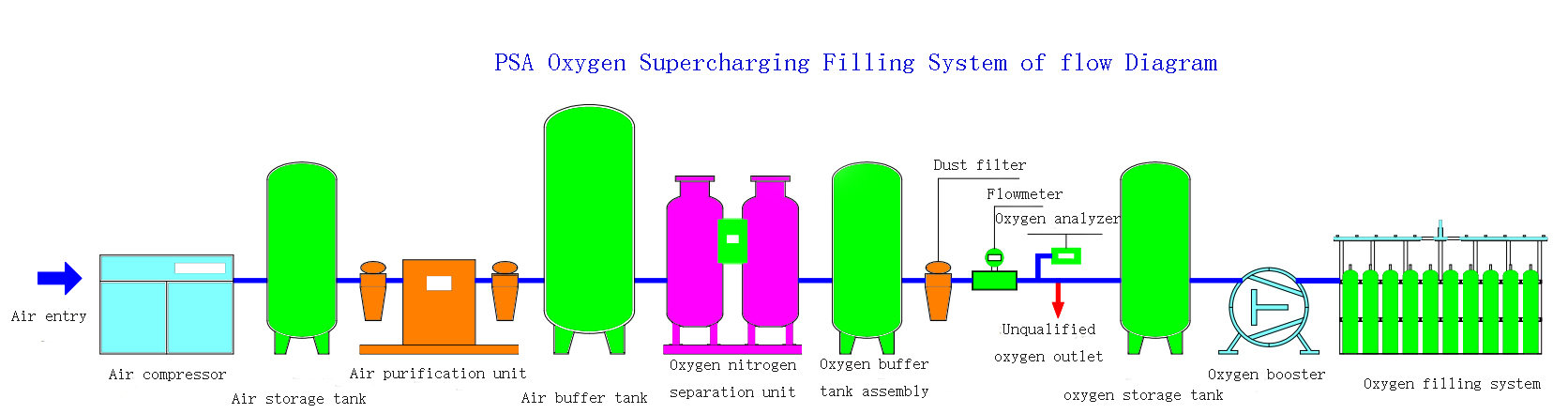

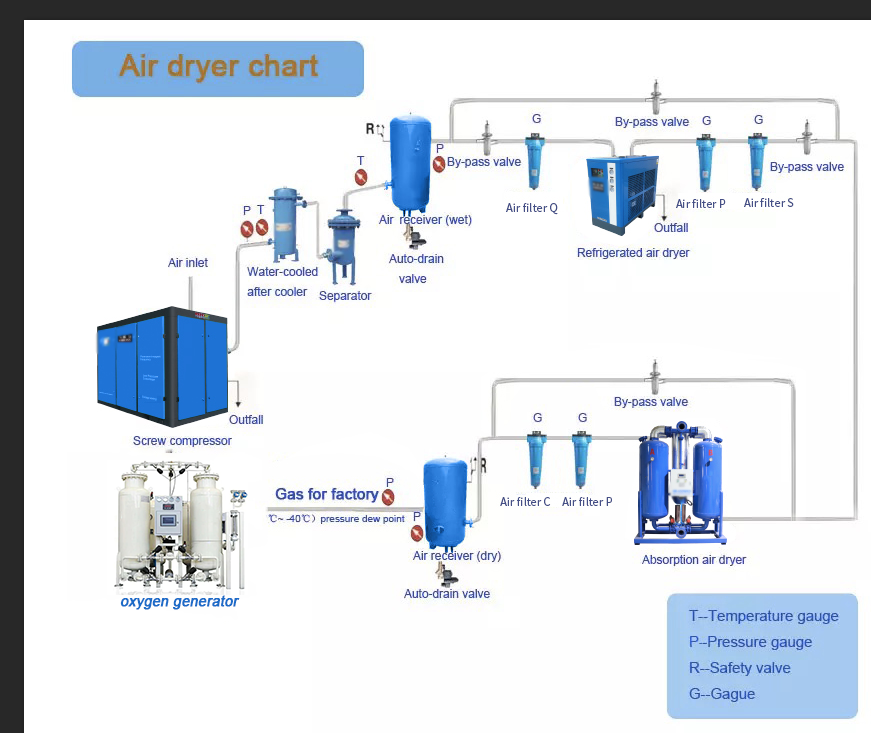

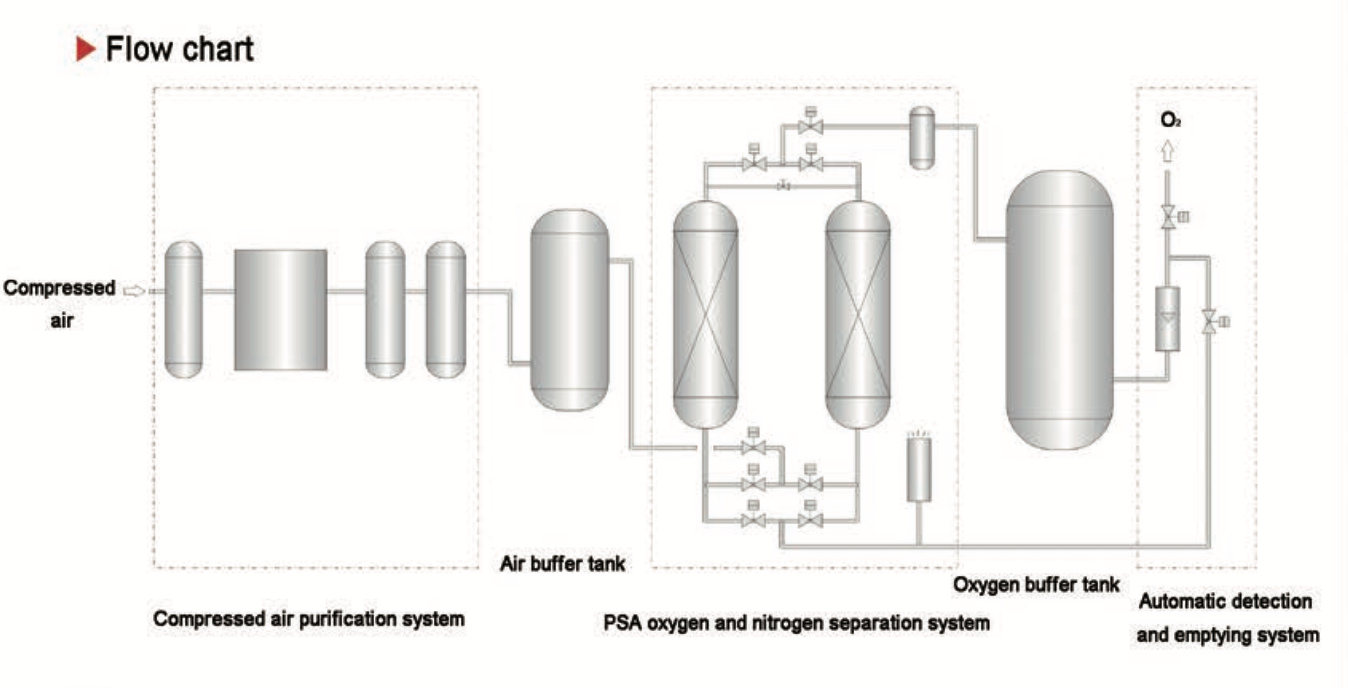

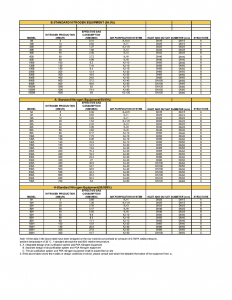

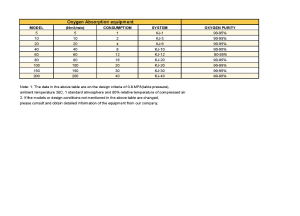

PSA OXYGEN ADSORPTION EQUIPMENT

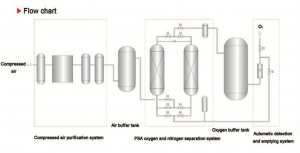

WORKING PRINCIPLE:

AFTER REMOVING IMPURITIES SUCH AS OIL, WATER AND DUST IN THE AIR PURIFICATION SYSTEM, COMPRESSED AIR ENTERS THE ADSORPTION TOWER CONTAINING ZEOLITE MOLECULAR SIEVE. NITROGEN, CARBON DIOXIDE, AND WATER VAPOR IN THE AIR ARE ADSORBED BY MOLECULAR SIEVE IN LARGE QUANTITIES, WHILE OXYGEN PASSES THROUGH THE ADSORBENT DUE TO THE LARGE DIFFUSION RATE, AND OXYGEN AND NITROGEN SEPARATION IS COMPLETED.

WHEN THE NITROGEN AND OTHER IMPURITIES IN THE ADSORPTION TOWER REACH SATURATION, THE PRESSURE IS REDUCED TO DESORPTION AND REGENERATION OF THE ZEOLITE MOLECULAR SIEVE OCCURS, WHICH CAN THEN BE REUSED.

USING TWO ADSORPTION TOWERS UNDER THE CONTROL OF PLC CYCLE WORK, ENSURES CONTINUOUS PRODUCTION OF HIGH-QUALITY OXYGEN.

TECHNICAL CHARACTERISTICS:

1. LOW ENERGY CONSUMPTION, STRONG ADAPTABILITY, FAST GAS PRODUCTION, EASY TO ADJUST THE PURITY.

2. PERFECT PROCESS DESIGN, OPTIMAL USE EFFECT.

3. MODULAR STRUCTURE DESIGN, SAVING FLOOR SPACE.

4. SIMPLE OPERATION, STABLE PERFORMANCE, HIGH DEGREE OF AUTOMATION, CAN ACHIEVE UNMANNED OPERATION.

5. REASONABLE INTERNAL COMPONENTS, UNIFORM AIRFLOW DISTRIBUTION, REDUCE THE IMPACT OF HIGH-SPEED AIRFLOW.

6. UNIQUE PROTECTION MEASURES OF CARBON MOLECULAR SIEVE, EXTEND THE SERVICE LIFE OF CARBON MOLECULAR SIEVE.

7. THE USE OF FAMOUS BRAND KEY COMPONENTS IS AN EFFECTIVE GUARANTEE OF EQUIPMENT QUALITY.

8. THE NATIONAL PATENT TECHNOLOGY OF AUTOMATIC AIR VENT DEVICE IS USED TO ENSURE THE QUALITY OF FINISHED NITROGEN.

9. INCLUDES A VARIETY OF FAULT DIAGNOSIS, ALARM AND AUTOMATIC PROCESSING FUNCTIONS.

10. OPTIONAL TOUCH SCREEN DISPLAY, DEW POINT DETECTION, ENERGY SAVING CONTROL, DCS COMMUNICATION, ETC.

TECHNICAL INDICATORS:

OXYGEN PRODUCTIONS: 5 TO 200NM3/H

OXYGEN PURITY: 90% TO 95%

OXYGEN PRESSURE: 0.1 TO 0.4MPA (ADJUSTABLE)

DEW POINT: -40OC OR -60OC

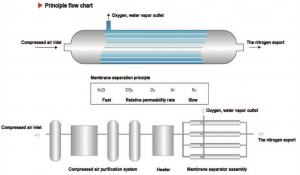

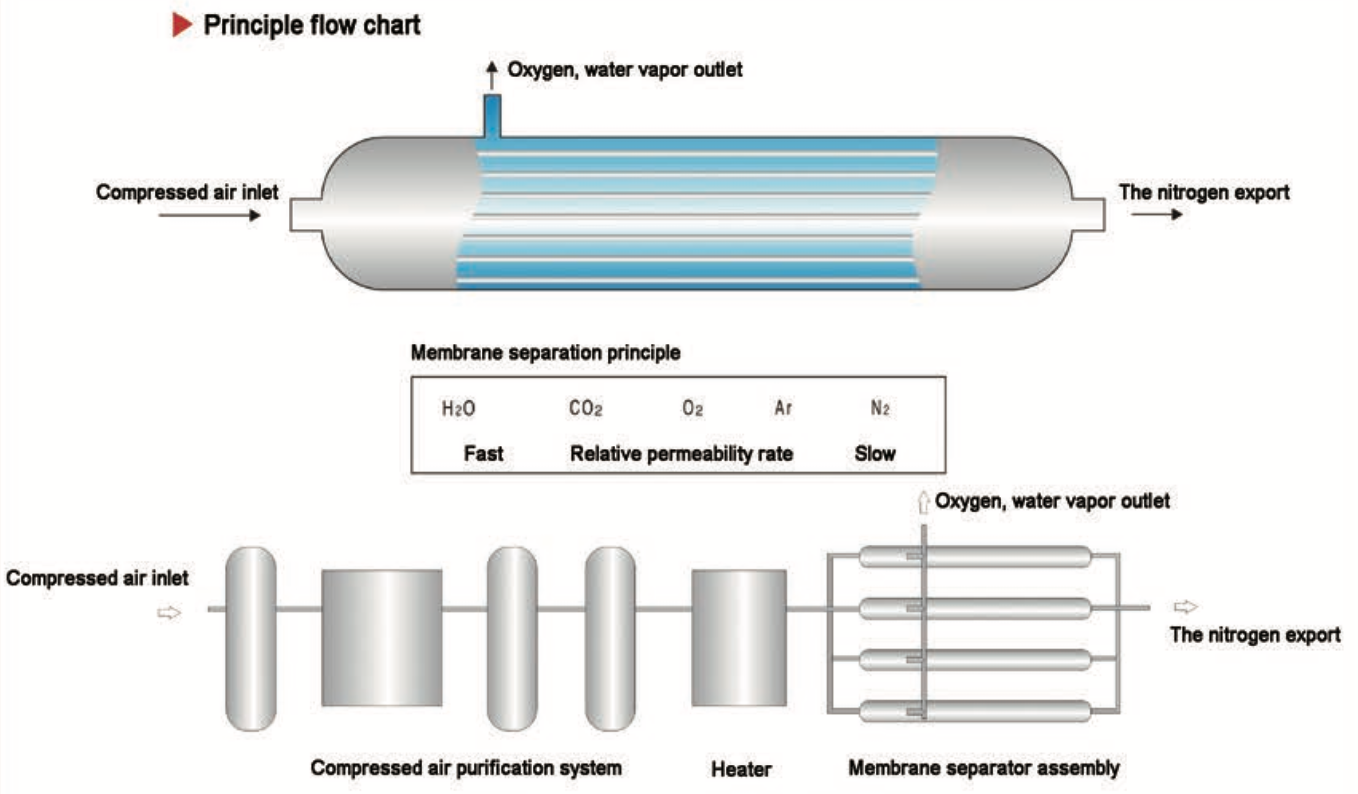

MEMBRANE NITROGEN SEPARATION EQUIPMENT

TECHNICAL CHARACTERISTICS:

1. SIMPLE OPERATION, RELIABLE OPERATION, HIGH DEGREE OF AUTOMATION, NO MOVING PARTS, NO CYCLE SWITCH, MEETS THE LONG-TERM CONTINUOUS OPERATION REQUIREMENTS.

2. EASY TO START/STOP, NITROGEN CAN BE PRODUCED WITHIN A SHORT TIME.

3. LOW ENERGY CONSUMPTION, CONTINUOUS ADJUSTABLE NITROGEN PURITY.

4. THE GAS SEPARATION PROCESS IS NOISELESS, POLLUTION-FREE, DOES NOT PRODUCE HARMFUL WASTE, AND HAS HIGH PURITY LEVELS OF NITROGEN PRODUCTION.

5. THE NITROGEN PRODUCTION CAPACITY OF THE SYSTEM CAN BE EXPANDED BY ADDING MEMBRANE COMPONENTS TO MEET THE NEEDS OF CUSTOMERS FOR DIFFERENT NITROGEN PRODUCTION.

6. INCLUDES THE FILM GROUP INTAKE QUALITY DETECTION AND PROTECTION DEVICE, TO ENSURE THE QUALIFIED GAS INTO THE FILM ASSEMBLY AND TO IMPROVE THE SERVICE LIFE OF THE FILM.

7. WIDE RANGE OF APPLICATION, ABLE TO RESIST MANY CHEMICAL POLLUTANTS.

8. OPTIONAL REMOTE MONITORING SYSTEM, PURITY AUTOMATIC ADJUSTMENT DEVICE, DCS COMMUNICATION, ETC.

TECHNICAL INDICATORS:

NITROGEN PRODUCTION: 5 TO 2000NM3/H

PURITY OF NITROGEN: 95% TO 99.9%

NITROGEN PRESSURE: 0.1 TO 1.2MPA (ADJUSTABLE)

NITROGEN DEW POINT: -40OC OR -60OC

WORKING PRINCIPLE:

MEMBRANE SEPARATION NITROGEN PROCESSING TECHNOLOGY IS BASED ON THE NITROGEN AND OXYGEN IN THE AIR UNDER THE ACTION OF PRESSURE DIFFERENCE ON BOTH SIDES OF MEMBRANE. PROCESS: THE MEMBRANE OF THE DIFFERENT SOLUBILITY AND DIFFUSION COEFFICIENT, WATER VAPOR PERMEABILITY FAST, OXYGEN AND OTHER GASES GO THOUGH THE MEMBRANE FIRST THEN BECOME RICH GAS, OXYGEN PERMEABILITY AND ENRICHMENT OF NITROGEN THEN BECOMES DRY AMMONIA GAS, RICH OXYGEN NITROGEN SEPARATION OCCURS.