Description

DETAILS:

THE AUTOMATIC MASK MACHINE CAN PRODUCE DISPOSABLE FACE MASKS WITH EXTERNAL EARS. AFTER PROCESSING, THEY CAN BE STERILIZED ACCORDING TO THE STANDARD OF SURGICAL MASKS TO MEET THE APPLICATION REQUIREMENTS.

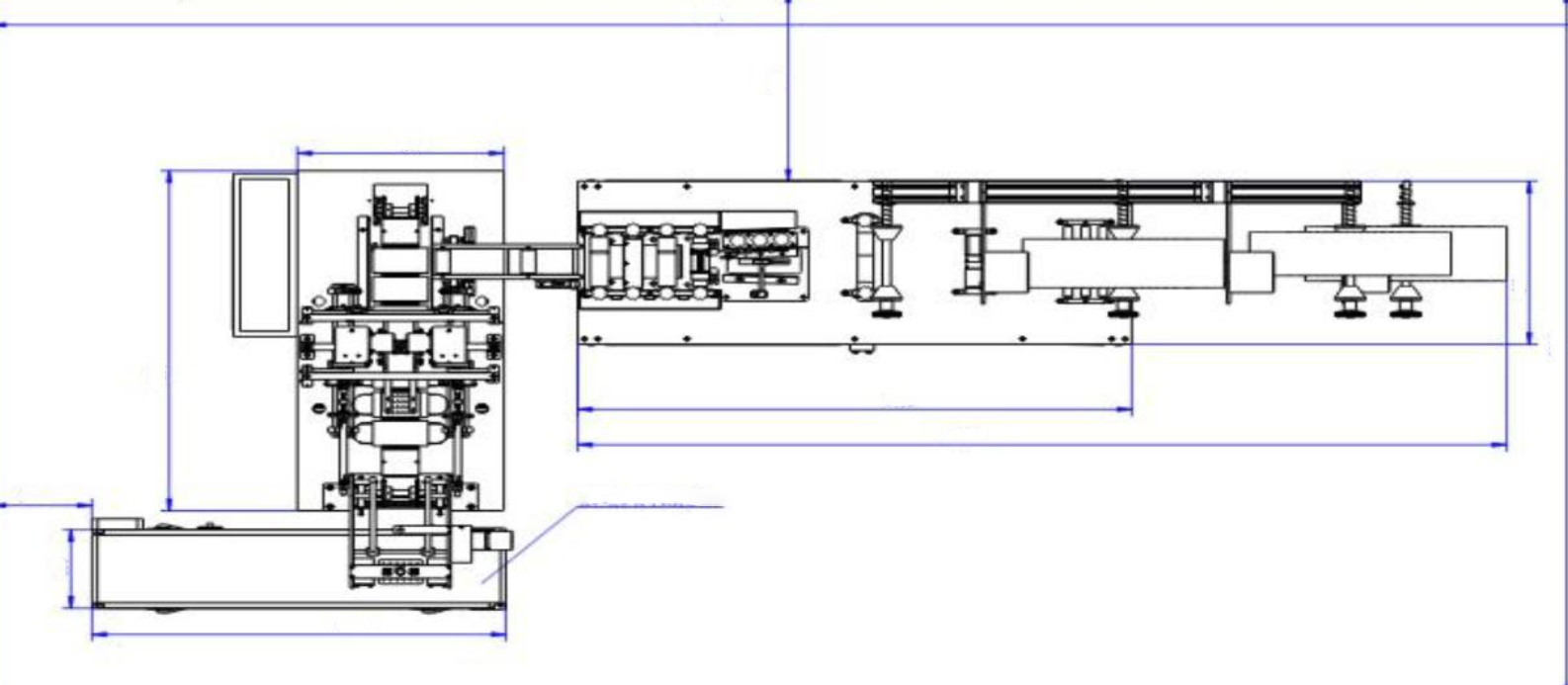

THE EQUIPMENT PRODUCTION LINE IS MAINLY COMPOSED OF A MAIN BODY MACHINE, A CONVEYING LINE AND AN EAR BAND WELDING MACHINE. MAIN MACHINE OUTPUT PORT.

AFTER THE MASK BODY, THE MASK BODY SHEET IS TRANSPORTED TO THE EAR BAND WELDING MACHINE CONNECTED TO THE EAR BAND MACHINE BY THE CONVEYOR BELT STRUCTURE TO COMPLETE THE PRODUCTION OF A FLAT OUTER EAR MASK PRODUCT.

BASIC PARAMETERS

USE ENVIRONMENT: TEMPERATURE 10 TO 35 °, HUMIDITY 5 TO 35%, NO FLAMMABILITY AND CORROSIVENESS GAS

APPLICABLE MATERIALS: NON-WOVEN FABRICS (20 TO 25G / M2), MELTBLOWN FILTER CLOTHS (15 TO 30G / M2), SINGLE WIRE NOSE RIBS, ALUMINUM BARS, ETC.

WORKING SUPPLY VOLTAGE: 220V ACCORDING TO CUSTOMER REQUIREMENT

POWER FREQUENCY: 50Hz/60Hz ACCORDING TO CUSTOMER REQUIREMENT

TOTAL POWER OF EQUIPMENT: 3.5KW

ULTRASONIC FREQUENCY: 15 TO 20KHz

MAX FEEDING WIDTH: 200mm

OVERALL DIMENSION OF EQUIPMENT: 4200 X 1600 X 1700mm

MAX PRODUCTION CAPACITY: 0 TO 85 PCS / MIN

WEIGHT: 850KG

OPERATOR: 1 PERSON (ONE PERSON CAN OPERATE MANY SETS MACHINES)

EQUIPMENT COMPOSITION

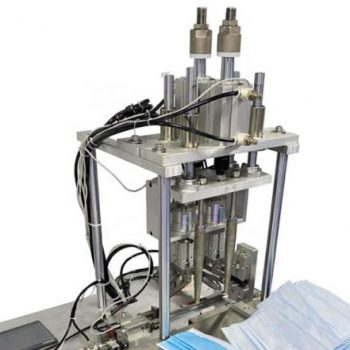

THE MACHINE IS COMPOSED OF FEEDING UNIT, FORMING UNIT AND WELDING EAR BELT. THREE ROLLS OF CLOTH CAN BE PLACED ON THE LOADING RACK AND ONE ROLLS NOSE BAR. THE FORMING MACHINE CONSISTS OF A FRAME, A CONVEYING DEVICE, AN ULTRASONIC GENERATOR (WELDING JOINT) AND A CUTTING DEVICE, ELECTROSTATIC EQUIPMENT, OPERATION PANEL ETC.

FEATURES

GOOD WELDING EFFECT AND LOW FAILURE RATE.

HIGH PRODUCTION SPEED, UP TO ABOUT 85 TABLETS PER MINUTE, CONTINUOUS PRODUCTION FOR 24 HOURS.

COMPUTER PLC CONTROL, SERVO DRIVE, HIGH DEGREE OF AUTOMATION.

PHOTOELECTRIC DETECTION OF RAW MATERIALS TO AVOID ERRORS AND REDUCE WASTE.

FRIENDLY MAN-MACHINE INTERFACE, EQUIPMENT ABNORMALITY AND LACK OF MATERIAL ALARM, SCREEN.

GUIDANCE TO DEAL WITH ABNORMAL PHENOMENA QUICKLY.