Description

MAIN CHARACTERISTICS:

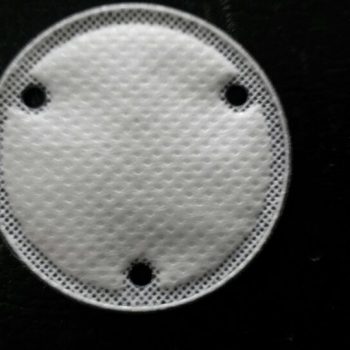

MAIN WORKING PROCESS: RAW MATERIALS UNWINDING AND TRANSFERRING, TWO RAW MATERIAL ROLLS COMBINATION FOLDING, ROLLING-CUTTING WITH HEATED EMBOSSING, PIECE COUNTING, FINISH PRODUCTS OUTPUT.

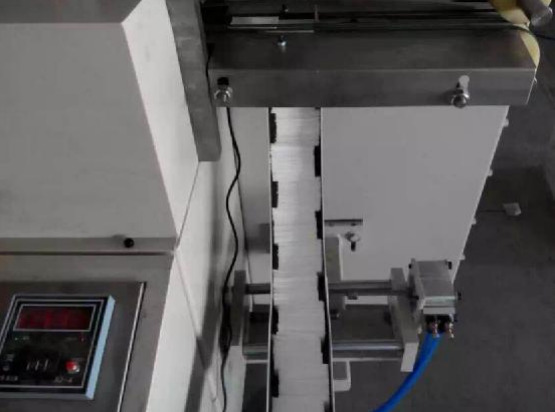

THE MACHINE EQUIPPED WITH 2 SETS OF RAW MATERIAL FEEDING SYSTEM AND IT EMBOSSING UNIT (HEATING TEMPERATURE CAN BE ADJUSTED) WHICH MAKES THE SEALING STRENGHT OF FINISHED PRODUCTS MUCH STRONGER THAN THE ONES MADE BY OTHER SUPPLIERS MACHINES.

IT ALSO HAS AUTOMATIC PNEUMATIC COUNTING SYSTEM AND AUTOMATIC RAW MATERIAL TRANSFERRING SYSTEM.

THE DEVICE USES FACTORY OWN DESIGNED MULTI-FUNCTIONAL FOLDING SYSTEM.

MAXIMUM DIAMETER OF MOTHER ROLLS CAN BE FED INTO THE MACHINE IS 1000mm

THE WIDTH OF MOTHER ROLLS YOU WILL USE DEPENDS ON THE SIZE OF FINISH PRODUCT YOU WANT TO MAKE.

THE FINISH PRODUCTS SIZE CAN BE MADE ACCORDING TO CLIENTS REQUEST.

THE MACHINE HAS HIGH PRODUCING SPEED, HIGH RUNNING STABLENESS, ACCORDING TO WITH SANITARY STANDARD.

THE MACHINES BEARING ARE ALL MADE OF INTERNATIONAL GOOD QUALITY 45# STEEL.

THE WORKING TABLE AND THE PARTS OF THE MACHINE WHICH WILL AFFECT THE CLEANLINESS OF THE FINISHED PRODUCTS ARE ALL MADE OF 304# STAINLESS STEEL.

THE MACHINE FREQUENCY CONVERTER (TRANSDUCER) TO CONTROL THE PRODUCING SPEED. THE ELECTRICAL PARTS HAVE REASONABLE WIRE LAYOUT.

THE MACHINE HAS VERY LIGHT WORKING NOISE AND EASU OPERATION.

USE RUST-PREVENTING PAINT TO BRUSH THE SURFACE OF THE DEVICE.

TECHNICAL PARAMETERS:

PRODUCING SPEED: ABOUT 400 PCS PER MINUTE

POWER SUPPLY: 22V, 60Hz, 3 PHASES

TOTAL POWER: 3.0 KW

DEVICE DIMENSION: 3800mm X 1200mm X 1600mm (LXWXH)

DEVICE WEIGHT: 1200 KG

QUANTITY: 1