Description

MAIN CHARACTERISTICS:

MAIN WORKING PROCESS: RAW MATERIALS UNWINDING AND TRANSFERRING, EMBOSSING ON RAW MATERIALS WITH HEATING SYSTEM, PUNCHING THE RAW MATERIALS TO BE ROUND COTTON PADS, PIECE COUNTING, WASTE RAW MATERIALS COLLECTING, FINISH PRODUCTS OUTPUT.

USE MECHANICAL PUNCHING SYSTEM WHICH INSTALLS 4 SETS OF ROUND PUNCHING KNIVES (3 SETS WHEN THERE IS STITCHING AROUND THE EDGE OF THE ROUND COTTON PADS), WHICH ARE MADE OF JAPANESE RAW MATERIALS TO KEEP PUNCHING EFFEC NEAT AND PRECISE.

THE FINISHED ROUND COTTON PADS HAVE NO ROUGH SELVEDGE.

USE THE MOST REASONABLE ARRAYING WAY IN THE PUNCHING MOULD TO MINIMIZE THE LOSS OF RAW MATERIAL IN THE REAL PRODUCTION.

THEN THE COST OF FINISH PRODUCTS WILL BE MUCH MORE DECREASED.

INSTALL 2 SETS OF MECHANICAL TENSION CONTROLLING SYSTEM IN THE MACHINE.

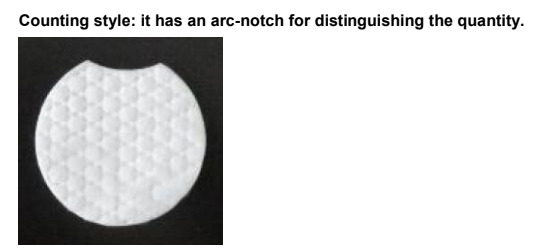

INSTALL AUTOMATIC PIECE-COUNTING (ARC-NOTCH) SYSTEM WHICH IS INVENTED BY OUR FACTORY.

USE CAM TRANSMISSION SYSTEM WHICH IS EQUIPPED WITH SETS OF SPECIALLY-MADE WEARABLE RUBBER TRANSFERRING ROLLERS AND OTHER PARTS ARE USING ALUMINUM ALLOY ROLLERS TO TRANSFER THE RAW MATERIALS.

FINISH PRODUCT OUTPUT IS IN VERTICAL ARRANGEMENT.

THE THICKNESS OF THE STAINLESS STEEL IS (1.0mm TO 4.0mm)

ALL THE ELECTROPLATING PARTS ARE ELECTROPLATED TWICE TO PROMISE THE FINE AND CLEAN SURFACE OF THE MACHINE.

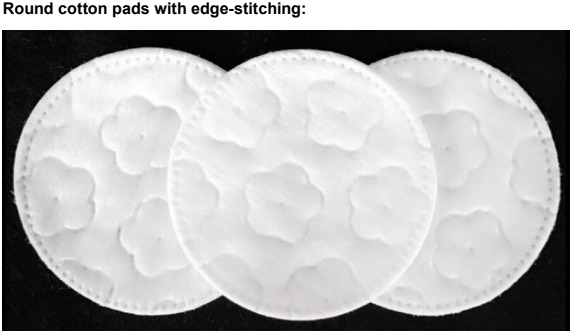

WITH EDGE STITCHING AND EMBOSSING

MAIN TECHNICAL PARAMETERS:

OUTER DIAMETER OF ROUND COTTON PAD 58mm 9OR ACCORDING TO CLIENTS REQUEST)

PRODUCING SPEED: 300 TO 400 PCS PER MINUTE

DIAMETER OF RAW MATERIAL MOTHER ROLL 1000mm

WIDTH OF RAW MATERIAL MOTHER ROLL

245 TO 250 mm (PADS WITHOUT STITCHING)

190 TO 195 mm (PADS WITH EDGE-STITCHING)

POWER SUPPLY: 220V, 60Hz, 5.5 KW

DEVICE WEIGHT: 2000 KG

DEVICE DIMENSION 3000mm X 1200mm X 1900mm (LXWXH)

QUANTITY: 1