Description

MAIN CHARACTERISTICS:

MAIN WORKING PROCESS: RAW MATERIALS UNWINDING AND TRANSFERRING, EMBOSSING RAW MATERIALS, VERTICAL CUTTING (WIDTH CUTTING), HORIZONTAL CUTTING ( LENGTH CUTTING),

PIECE-COUNTING, FINISHED PRODUCTS OUTPUT.

INSTALL 1 SET OF “STEEL ROLLER TO STEEL ROLLER” EMBOSSING SYSTEM ( WITH HEATING UNITS) IN THE MACHINE.

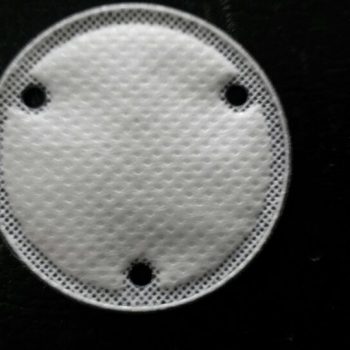

THE EMBOSSING DESIGN CAN BE MADE ACCORDING TO CLIENTS REQUEST.

USE FORTEX STYLE VERTICAL SLITTING SYSTEM AND HORIZONTAL CUTTING SYSTEM WHICH ARE BOTH MADE OF HIGH-QUALITY STEEL AND IRON FROM JAPAN TO PROMISE HIGH SLITTING AND CUTTING PRECISION AND FINISHED PRODUCT WITHOUT ROUGH EDGES.

INSTALL THE PNEUMATIC RIGHT AND LEFT LADDER STYLE COUNTING SYSTEM TO MAKE THE WORKERS DISTINGUISH THE NUMBER OF FINISHED COTTON PADS VERY EASILY.

SIZE OF THE FINISHED PRODUCTS CAN BE ADJUSTED EASILY AND FREELY.

INSTALL HIGH PRECISION OXYGENATION ALUMINUM ALLOY CRINKLE- REMOVING ROLLERS FOR STRETCHING THE RAW MATERIAL AND MAKE IT RUN MORE SMOOTHLY.

USE FREQUENCY CONVERTER TO ADJUST THE RUNNING SPEED OF THE MACHINE.

ELECTRONIC SYSTEM HAS REASONABLE AND FINE WIRE LAYOUT AND ITS VERY EASY TO BE OPERATED. HIGH-QUALITY FRAME OF THE MACHINE MAKES THE WORKING NOISE VERY LIGHT.

WE USE 36mm THICK SOLID IRON AND STEEL TO MAKE THE WHOLE FRAME OF THE MACHINE.

MAIN TECHNICAL PARAMETERS:

MAXIMUM WIDTH OF RAW MATERIAL: 900mm

MAXIMUM DIAMETER OF ROLL MATERIAL: 1000mm

SLITTING UNIT QUANTITY: 18 SETS

SIZE FINISHED PRODUCT: L:50mm TO 100mm X W:30mm TO 500mm

PRODUCING SPEED: 1000 TO 1500 PCS PER MINUTE

POWER SUPPLY: 220V, 60Hz 3 PHASES 5.5KW

DEVICE WEIGHT: 2300kg

DEVICE DIMENSION: 2800mm×1900mm×1600mm (LXWXH)

QUANTITY: 1