Description

DETAILS:

THE CHARACTERISTICS OF FACE MASK MACHINE

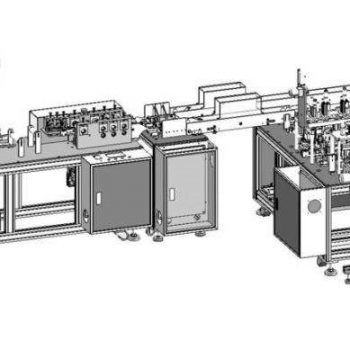

FULLY AUTOMATIC FACE MASK PRODUCTION LINE IS THE IDEAL EQUIPMENT FOR PRODUCING HIGH-END MASKS. THE MACHINE IS COMPOSED OF THREE DEVICES, ONE MASK BODY MACHINE, TWO EAR BAND MACHINES

THIS MASK PRODUCTION LINE IS A FULLY AUTOMATIC ONE-TO-TWO MASK MAKING MACHINE, ONE BODY MACHINE COMBINED WITH TWO EAR BAND MACHINES.

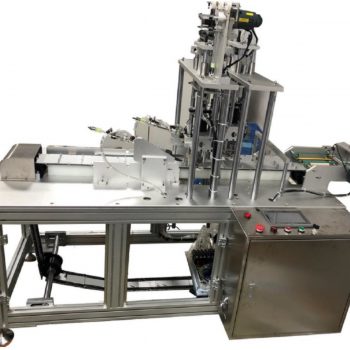

THE BODY MACHINE FINISHING THE ACTION OF MATERIAL TRANSFERRING, FOLDING, PRESSING, NOSE BRIDGE FEEDING, MASK FORMING AND MASK SHEET CUTTING.

AFTER THE BODY MACHINE DISCHARGED THE MASK BODY SHEET, A CONVEYOR COLLECTS THE MASK BODY SHEET AND TRANSFERS THEM FORWARD; A FLAPPING DEVICE TURN THE MASK BODY SHEET IN 180 DEGREES AND ALTERNATIVELY TRANSFER THE MASK BODY SHEET INTO TWO CONVEYOR BELTS THAT CONNECTS TWO EAR BAND MACHINE. IN THE EAR BAND MACHINE, THE MASK BODY SHEET IS POSITIONED AND THEN IS WELDED WITH THE EAR BAND BY ULTRASONIC WELDING DEVICE; THE FINISHED MASKS ARE THEN DISCHARGED AUTOMATICALLY.

MACHINE FEATURES:

> INCORPORATES SERVO AND TOUCH SCREEN USER INTERFACE.

> ALL THE MAIN PARTS ARE MADE OF PREMIUM STAINLESS STEEL AND ALU-ALLOY MATERIAL, AND MACHINED BY ADVANCED HIGH PRECISION CNC TOOLING MACHINES.

> PHOTOELECTRIC (OPTICAL FIBER) DETECTION OF RAW MATERIALS TO AVOID ERRORS AND REDUCE WASTE.

> AUTOMATIC TENSION CONTROL OF RAW MATERIALS TO ENSURE BALANCED RAW MATERIAL TENSION.

> ONE TO THREE LAYERS OF MASK BODY ACCORDING TO CUSTOMER’S DEMAND.

> CHANGING THE MOLD CAN PRODUCE MASKS OF DIFFERENT SIZES AND STYLES.

> MECHANICALLY ADJUSTABLE PART: THE FOLDED PART CAN BE ADJUSTED;

> MASKS WITH 1-3 LAYERS OF FABRIC (ACTIVE CARBON MATERIAL CAN BE ADDED IN THE MIDDLE); WELDING STRENGTH CAN BE ADJUSTED.

> AUTOMATIC DELIVERY OF RAW MATERIALS.

> AUTOMATIC FOLDING AND PRESSING

> AUTOMATIC NOSE BRIDGE FEEDING

> AUTOMATIC MASK FORMING AND CUTTING

> CONNECTION TRANSFER UNIT

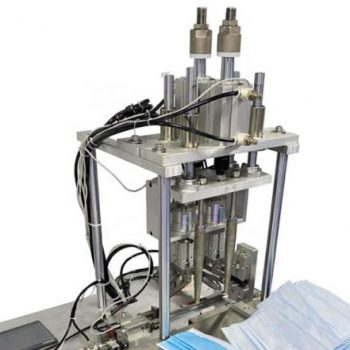

> AUTOMATIC EAR BAND FEEDING AND WELDING

> AUTOMATIC FINISHED PRODUCT DISCHARGING

MAIN TECHNICAL PARAMETERS:

MACHINE SIZE: 6250 X 3500 X 1980mm

AIR PRESSURE: 0.5~0.6MPA

MASK SPECIFICATIONS STANDARD: 175 X 95mm

MAXIMUM OUTPUT: 80PCS/MIN

MACHINE WEIGHT: 1000KGS

POWER SUPPLY: 220V 50Hz

POWER: ≤13.5Kw

COMPRESSED AIR CONSUMPTION: 1 TO 1.5 M3/MIN

OPERATING HEIGHT OF EQUIPMENT:800 TO 900mm

OPERATING AMBIENT TEMPERATURE: 10 TO 35℃

WORKING ENVIRONMENT HUMIDITY: 5 TO 50%RH

MAIN CONFIGURATION LIST:

PLC: INOVANCE

DRIVER: INOVANCE

SERVO MOTOR: INOVANCE

STEPPING MOTOR: YAKO

CYLINDER: AIRTAC

SOLENOID VALVE: YPC

MAGNET SWITCH: AIRTAC