Description

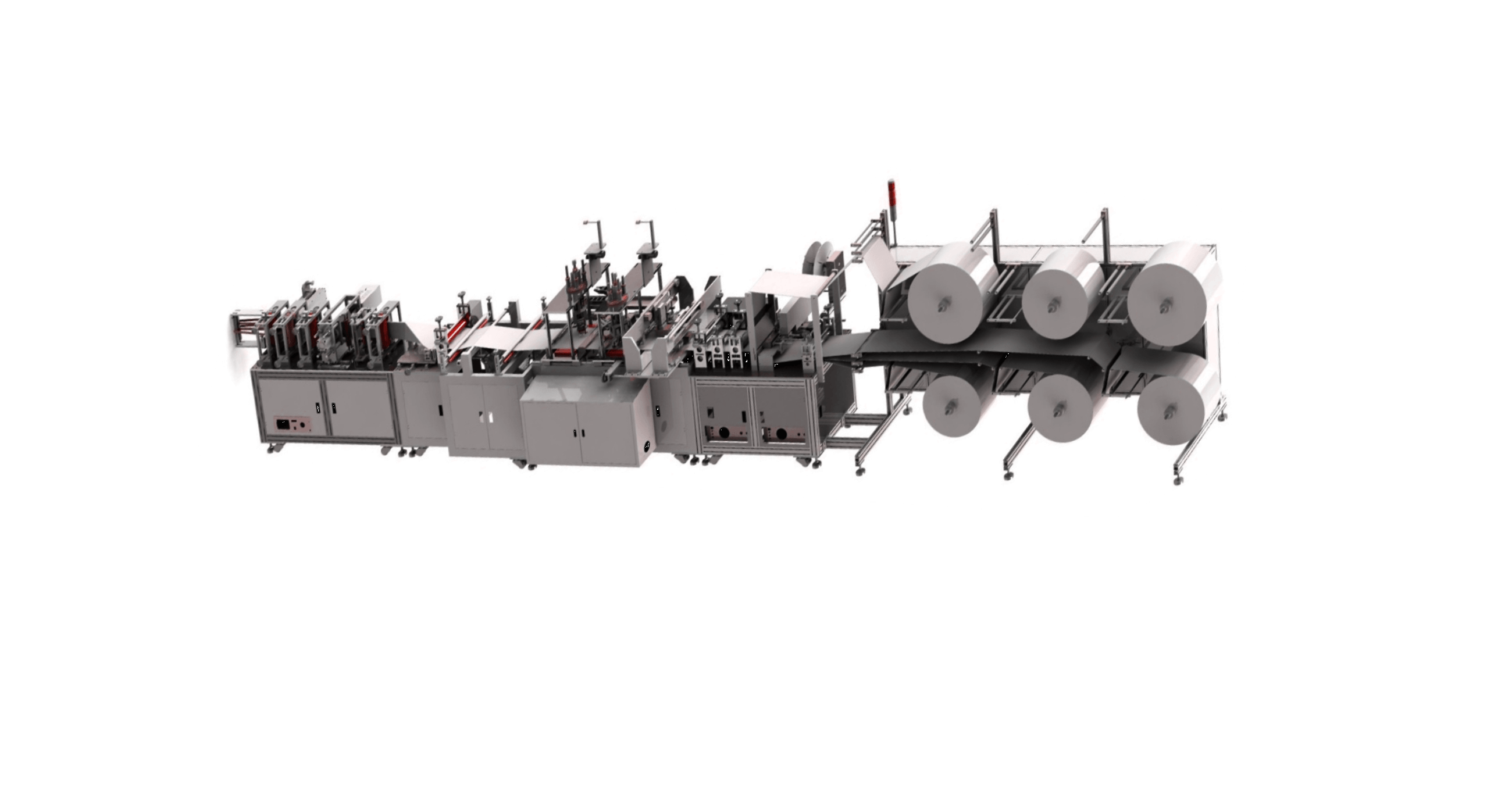

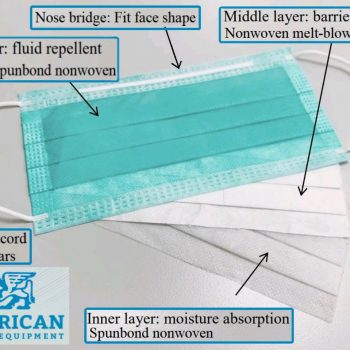

FFP2/N95 MASK

1) ULTRASONICALLY WELDS NOSE BRIDGE

2) ULTRASONICALLY WELDS MASK LAYERS TOGETHER

3) PUNCHES HOLE FOR RESPIRATOR VALVE (OPTIONAL)

4) MULTI-LAYER ROLL WELDING

5) ULTRASONICALLY WELDS EAR BAND MATERIAL ONTO BODY OF MASK

SPECIFICATIONS

CAPACITY: APPROXIMATELY 40 TO 50 PER MINUTE

DIMENSIONS: 9700 X 1110 X 2200MM (L X W X H)

NET WEIGHT: 2500 KGS

AMBIENT TEMPERATURE: 25 ± 5 °C

RELATIVE HUMIDITY: MINIMUM 40%, MAXIMUM 60%

ALTITUDE ABOVE SEA LEVEL: 0 TO 1000 METERS (OTHER HEIGHTS POSSIBLE ON REQUEST)

COMPRESSED AIR: 6 BAR, CONSTANT, CLEAN, OIL-FREE, DRY, CLASS 4 ACCORDING TO ISO 8573-1

VOLTAGE: 220V

FREQUENCY: 60/50 HZ (AS PER CUSTOMER REQUIREMENT) ± 0.5%

POWER CONSUMPTION: 10 KVA

MATERIALS TO BE FURNISHED TO US UPON PURCHASE

SERVICES AND SUPPLIES OF THE CUSTOMER TO BE DELIVERED TO US DURING PRODUCTION OF THE MACHINE

CONSUMABLES (E.G. FLEECES, EAR BANDS, NOSE STRIP MATERIAL, INK, ETC.) FOR AT LEAST 9,000 MASKS (PER MACHINE) MUST BE MADE AVAILABLE TO US FREE OF CHARGE AT LEAST 4 WEEKS BEFORE THE PLANNED DELIVERY DATE OF THE MACHINE.

THE LAYOUT OF THE LABELING IS TO BE HANDED OVER TO US IN DWG OR DXF DRAWING FORMAT WHEN THE ORDER IS PLACED.

RESERVATIONS

TECHNICAL USABILITY OF THE TECHNOLOGY SPECIFIED BY THE CLIENT

THE PROCESS AND PRODUCT RESPONSIBILITY FOR THE MANUFACTURED PRODUCTS LIES WITH THE CUSTOMER AUTOMATION-SUITABLE PROCESSES AND MATERIALS

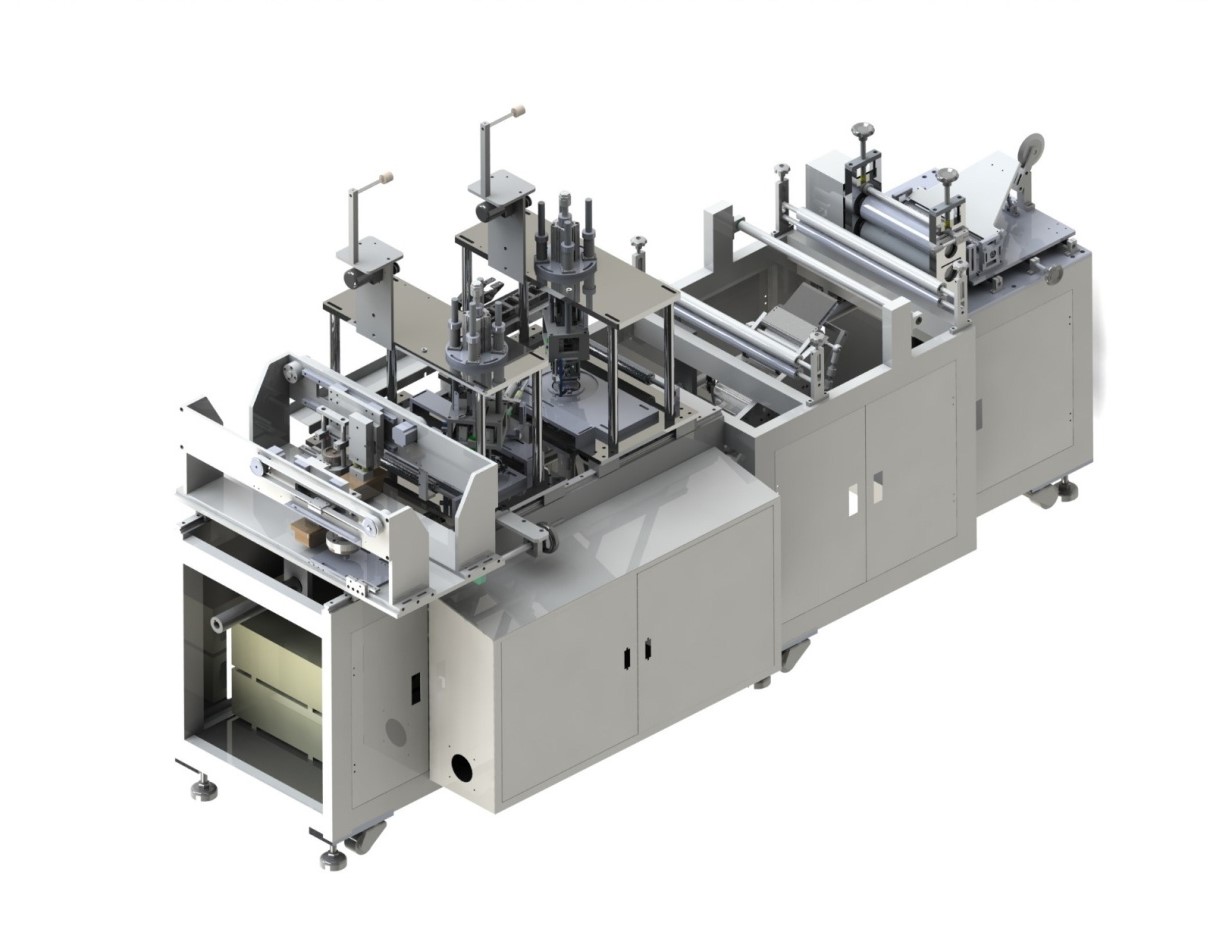

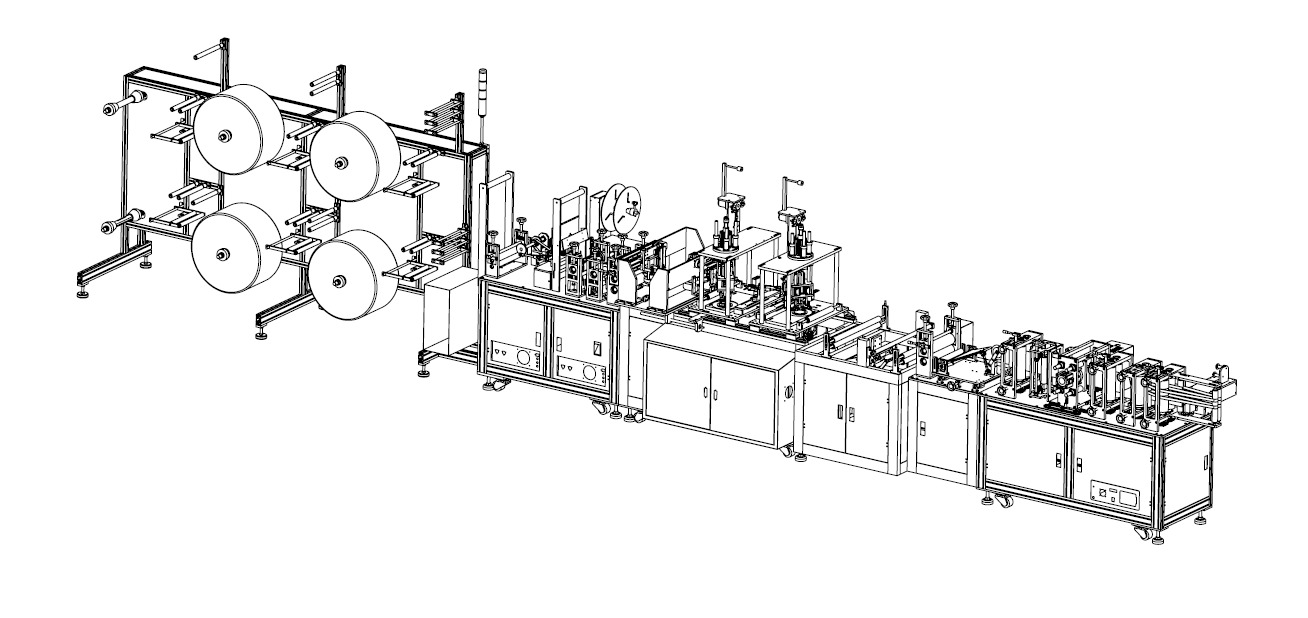

MACHINE STRUCTURE

MATERIAL UNWINDER FOR 3 ROLLS. ALSO, OPTIONALLY AVAILABLE UNWINDER FOR 4 OR 6 ROLLS.

MAXIMUM ROLL DIAMETER: 600mm

MAXIMUM ROLL WIDTH: 300mm

ROLL HOLDERS AND GUIDE ROLLS WEB TENSION OVER DANCER ROLL

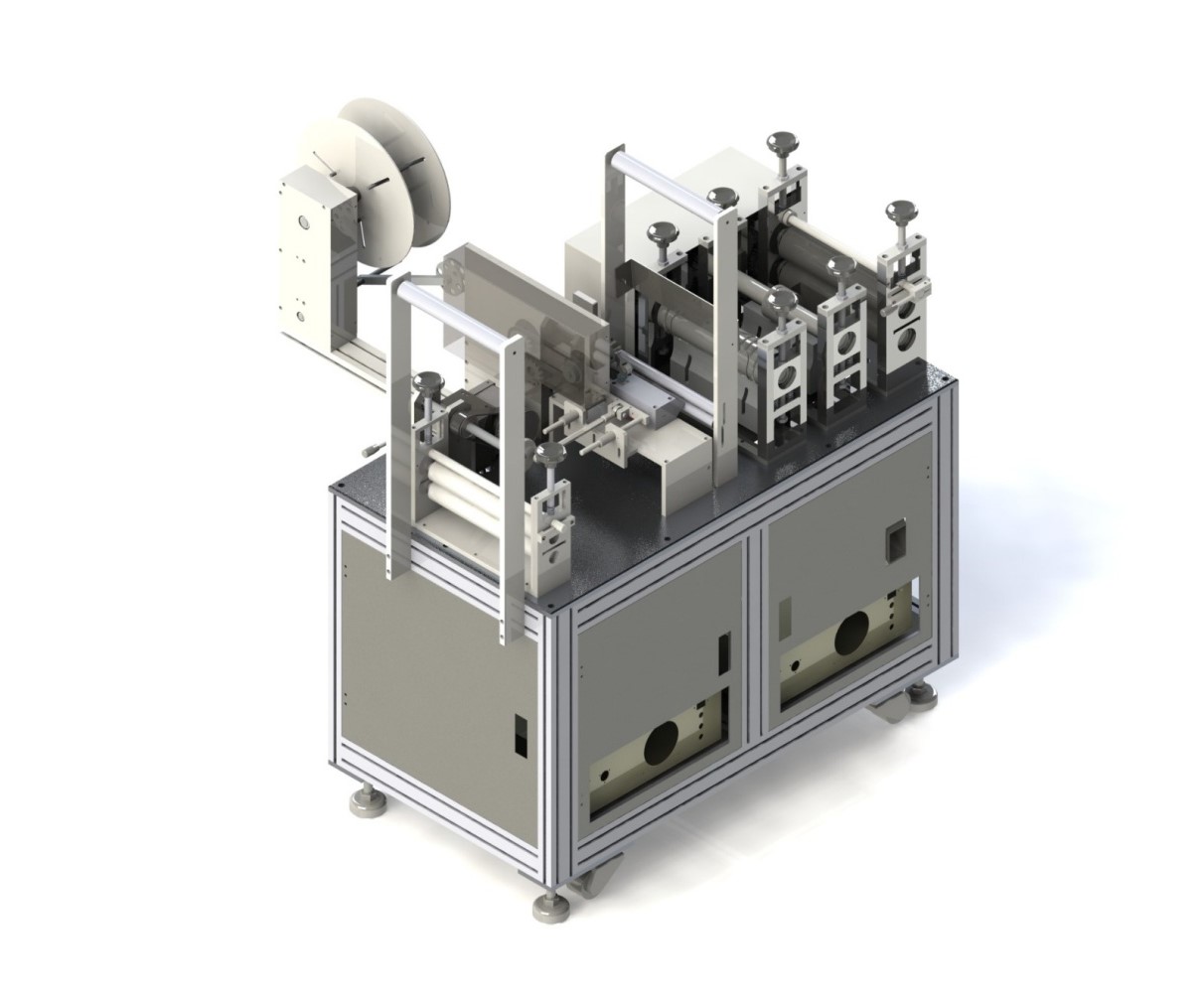

NOSE WIRE UNIT

INSERTS NOSE WIRE

WITH UNWINDER AND CUTTER FOR FIXING WIRE

ULTRASONIC WELDING SYSTEM, CONVEYOR ROLLERS AND PRESSURE CONTROL MECHANISM CUTTING SYSTEM

MIDDLE UNIT

WITH PRINTING STATION (OPTIONAL)

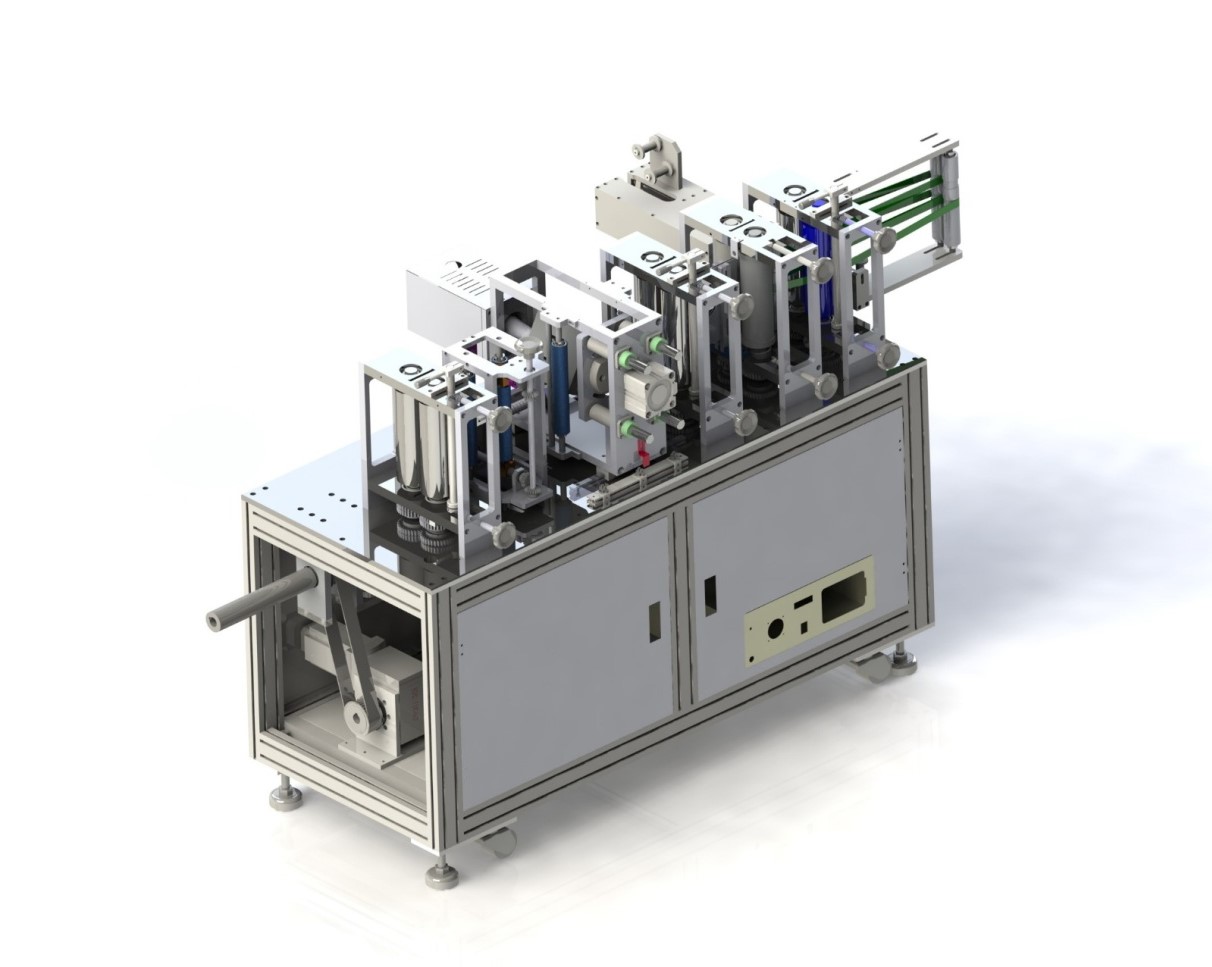

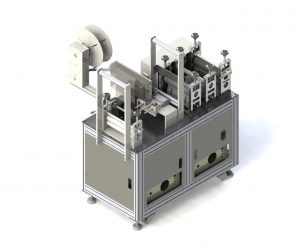

EAR LOOP MATERIAL (RIGHT & LEFT) AND ULTRASONIC WELDING (RIGHT AND LEFT)

WITH UNROLLER AND SCISSORS

MACHINE OUTLET UNIT

CUTTING UNIT FOR WASTE STRIPS

OUTPUT SHAFT FOR RESPIRATOR MASK: OUTPUT AS BULK MATERIAL

OUTPUT FOR WASTE STRIPS: TAKE-OFF ROLLERS

COLLECTING THE WASTE STRIP

OPTIONAL SOFTWARE PACKAGES

REMOTE ACCESS AND SERVICE

FREE-OF-CHARGE FOR 1 YEAR AFTER INSTALLATION, WITH SERVICE FEE REMOTE CALL AFTERWARDS

PRODUCTIVITY MONITORING

LOG-FILE, DATA ANALYSES TOOLS FOR PRODUCTIVITY AND DOWN-TIME, CUSTOMER-SPECIFIC SHIFT CALENDARS

DOCUMENTATION (1X PAPER AND 1X DATA CARRIER) IN ENGLISH LANGUAGE, CONSISTING OF:

• OPERATING INSTRUCTIONS

• CIRCUIT DIAGRAM

• PNEUMATIC DIAGRAM

• SPARE AND WEAR PARTS LIST

• CE DECLARATION OF CONFORMITY

ELECTRICAL CABINETS

SET OF RELAYS AND CONTACTS

PLC, HMI AND FREQUENCY CONVERTERS (SIEMENS)

ULTRASONIC GENERATORS AND CONVERTORS (BRANSON, HERRMANN, SONOTRONIC, WEBER)

FACTORY ACCEPTANCE TEST (FAT) AND SITE ACCEPTANCE TEST (SAT)

THE 1-HOUR FAT (PURE MACHINE RUNNING TIME) OF THE SYSTEM IS CARRIED OUT BEFORE DELIVERY IN THE MANUFACTURER’S FACTORY AND IS TO BE ACCOMPANIED BY THE CUSTOMER. AFTER COMPLETION OF THE PRELIMINARY ACCEPTANCE, THE CUSTOMER SHALL GIVE WRITTEN RELEASE FOR TRANSPORT.

ANY DEFECTS DISCOVERED DURING THE PRELIMINARY ACCEPTANCE WILL BE RECORDED IN AN OPEN POINTS LIST (OPL) AND WILL BE RECTIFIED BY THE MANUFACTURER, IF POSSIBLE BEFORE DELIVERY OR BEFORE THE START OF THE FINAL ACCEPTANCE.

THE FINAL ACCEPTANCE OF THE COMPLETED SYSTEM TAKES PLACE AT THE INSTALLATION SITE IN THE PRESENCE OF OUR PERSONNEL. DURING THE FINAL ACCEPTANCE TEST, THE AGREED TECHNICAL FEATURES MUST BE VERIFIED AND CONFIRMED BY THE CUSTOMER.

SHOULD THE ACCEPTANCE BE DELAYED FOR REASONS FOR WHICH WE ARE NOT RESPONSIBLE, WITHIN 30 DAYS AFTER DELIVERY HAS NOT TAKEN PLACE, OR THE SYSTEM IS PUT INTO OPERATION BEFORE ACCEPTANCE, THE SYSTEM IS ACCEPTED.