Description

ONE PLUS ONE

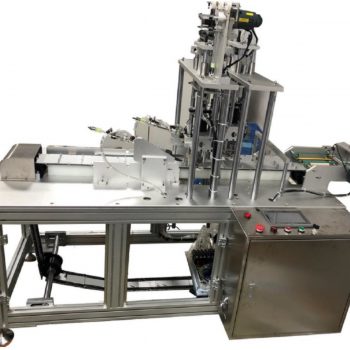

THE FULLY AUTOMATIC MASK MAKING MACHINE PRODUCE MASK WITH OVERALL AUTOMATION FROM RAW MATERIAL FEEDING TO INSERTING, SEALING INSIDE TO NOSE WIRE TO WELD EAR LOOP TO FINISHED MASK COMPLETELY.

THIS MACHINE CAN HELP TO SAVE PRODUCE COST (LABOR AND TIME).

THIS MACHINE IS LOWER FAILURE RATE AND EASY TO OPERATION.

THIS MACHINE CAN COUNT PRODUCTION QUANTITY AUTOMATICALLY.

THIS MACHINE MAKE THE 1 MASK BLANK MACHINE AND 1 EAR LOOP WELDING MACHINE WORK TOGETHER.

THE UNIT FEATURES:

1. IT IS A UNIT OF FULLY AUTOMATIC FACE MASK MAKING MACHINE. THIS MACHINE UNIFY 1 UNIT MASK BLANK AND 1 UNITS 1OUTER EARLOOP MACHINE BY A UNIT OF AUTOMATED DISPENSER.;

2. MASK BODIES PRODUCED ON MOTHER MACHINE CAN BE ALLOCATED ONTO 1 UNITS CHILD MACHINE AVERAGELY BY PLC AT THE SPEED OF 60PIECES PER MINUTE.;

3. ON THIS COMBINATION THE MASK BODY MACHINE CAN MATCH WITH 1/2/3/4UNITS OF EAR-LOOP MACHINE;

4. THE MACHINE IS MADE OF ALUMINUM ALLOY WHICH MAKES IT BEAUTIFUL, PREVENTED FROM RUST AND HAS A SMALL SIZE;

5. THE MACHINE CAN MAKE THE 1-5 LEVELS MASK BLANK AC CORDING FOR THE CUSTOMER’S REQUIRE WITH A HIGH OUTPUT;

6. YOU CAN ADJUST THE SIZE OF THE MASK BLANK AND THE FOLDING LOCATION;

7. THE DIRECTION OF THE EARLOOP IS OUTSIDE;

8. COMPARED WITH SUB-MASK PRODUCTION EQUIPMENT, THIS SET OF EQUIPMENT MORE EFFICIENT, MORE ECONOMICAL ARTIFICIAL;

9. THE COMPUTER PROGRAM CONTROL AND PHOTOELECTRIC DETECTION MAKE IT HAVE A HIGH RELIABILITY AND LOW FAILURE RATE.

THE MAIN TECHNICAL PARAMETERS:

CAPACITY (PIECES / MIN): 60

POWER SOURCE: AC220V 1PH 50HZ

MAIN DRIVE SERVO MOTOR POWER KW: 1.5KW

GEAR REDUCTION RATIO 1: 40

ULTRASONIC POWER KW 5KW FOR OUTER EARLOOP;

DIMENSIONS (L X W X H mm):

1. BLANK MACHINE: (L X W X H) 2030 X 700 X 1530mm

2. EAR LOOP MACHINE: (L X W X H) 1650 X 980 X 1900mm

3. LINK SPAN: (L X W X H) 2150 X 350 X 1330mm

4. MATERIAL REST: (L X W X H) 2200 X 620 X 1700mm

5. CONVEYOR: (L X W X H) 1220 X 400 X 750mm

MASK SIZE (L X W mm) 175 X 95mm; 145 X 90mm/125 X 80mm;

USE-ENVIRONMENT PURIFYING

AMBIENT TEMPERATURE -10 DEGREES CELSIUS ~+26 DEGREES CELSIUS.

SPARE PARTS:

1 CUTTING KNIFE QUANTITY: 1 SET

2 PLASTIC TAPE QUANTITY: 1 SET

3 CLIP QUANTITY: 1

4 CYLINDER QUANTITY: 1

MASK BLANK MAKING MACHINE

MASK EARLOOP WELDING MACHINE