Description

FOR AUTOMATIC AND CONTINUOUS PRODUCTION OF 100% COTTON CREPE BANDAGES FROM 100% COTTON GAUZE FABRICS. THE PRODUCTION LINE HAS 3 CONTINUOUS FUNCTIONS REALIZED BY 3 MACHINES:

FIRST MACHINE (MODEL 2-A) IS FOR PRE-WASHING AND MAKING THE CRINKLE-WEAVES (CREPE EFFECTS);

SECOND MACHINE (MODEL 2-B) IS FOR CONTINUOUS DRYING THE CREPE GAUZE BY HOT STEAM GENERATED BY WATER BOILERS;

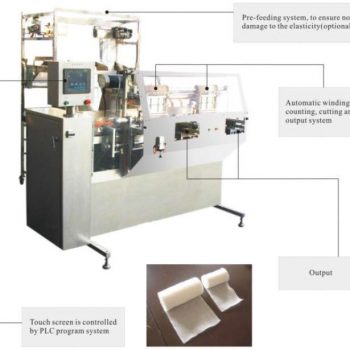

THIRD MACHINE (MODEL 2-C) IS FOR ROLLING THE CREPE GAUZE INTO BANDAGES AS PER PRE-SET LENGTH TO MAKE THE FINAL PRODUCT: CREPE BANDAGES (STANDARD SIZES: 4.5” x 4.1 YARDS)

PRODUCTION STEPS:

90CM WIDE COTTON GAUZE ROLL (RAW MATERIAL) IS TRI-FOLDING INTO 30CM WIDE GAUZE AND ROLLED UP INTO 800 METERS ROLL (3-PLY ROLL OF WIDTH 30CM AND LENGTH 800 METERS) BY OUR TRI-FOLDING EQUIPMENT (WHICH IS A SPATE ONE: MODEL T1)

THIS TRI-FOLDED ROLL (MADE BY T1) IS LOADED ON PRODUCTION LINE (MODEL T2) TO HAVE IT WASHED AND CRINKLED TO BE WEAVED, DRIED, AND RE-ROLLED INTO CREPE BANDAGES.

PRODUCTION SPEED:

MODEL T2 HAS 3 PRODUCTION CHANNELS; EACH CHANNEL MAKES 26 METERS CREPE GAUZE IN ONE MINUTE. SO TOTAL IS 78 METERS IN ONE MINUTE.

THE SECOND MACHINE (MODEL 2-B) HAS TWO KINDS OF DESIGN ACCORDING TO DIFFERENT CUSTOMERS AREA REQUIREMENTS: ONE KIND HAS 3 LAYERS STAINLESS CONVEYOR-TYPE WIRED NET FOR DRYING. ITS LENGTH IS 11 METERS AND WIDTH IS 4 METERS.

TO INSTALL THIS KIND OF EQUIPMENT, THE WORKSHOP CEILING HEIGHT SHALL NOT BE LESS THAN 3.2 METERS.

THE OTHER KIND HAS 1 LAYER STAINLESS CONVEYOR-TYPE WIRED NET FOR DRYING. ITS LENGTH IS 22 METERS AND WIDTH IS 3.2 METERS. TO INSTALL THIS KIND OF EQUIPMENT, THE WORKSHOP CEILING HEIGHT SHALL NOT BE LESS THAN 2.5 METERS.

FINAL PRODUCTION INTRODUCTION:

THE CREPE BANDAGE (CRINKLE GAUZE ROLLS) IS A STERILE, HIGHLY ABSORBENT GAUZE WRAP THAT PROVIDES A SOFT, SPONGY, SAFEGUARD FOR TENDER WOUND AREAS. IT PROVIDES FAST WICKING FROM THE WOUND SITE AND SUPERIOR ABSORBENCY.

IT IS MADE WITH PRE-WASHED, FLUFF-DRIED WOVEN GAUZE TO PROTECT THE WOUND WHEN REDUCING THE RISK OF INFECTION. IT IS ALSO IN THE HEALTH CARE INDUSTRY AS KERLIX GAUZE ROLLS.