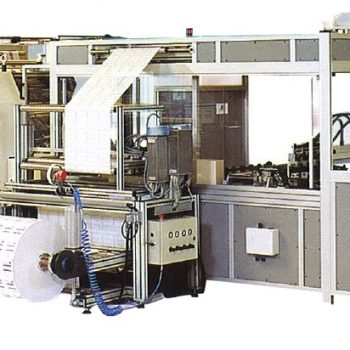

Description

IT IS ELECTRICAL-MECHANIC EQUIPMENT FOR AUTOMATIC SEWING OF NON-ELASTIC GAUZE BANDAGES

ALL THE PRODUCTION PARAMETERS ARE SET ON THE ENGLISH-VERSION TOUCH SCREEN CONTROL PANEL IN THIS EQUIPMENT. THE LOADING OF BIG BANDAGE ROLL AND TAKING THE READY-MADE SMALL BANDAGE ROLLS AT THE BASKET (BOX) UNDER THE OUTPUT ARE MANUALLY.

INPUT WIDTH: NON-ELASTIC GAUZE BANDAGE IN BIG ROLL OF WIDTH FROM 5CM (MINIMUM) TO 15CM (MAXIMUM)

BANDAGE ROLL: LENGTHS FROM 1.5 TO 10 METERS ADJUSTABLE AND WIDTH FROM 50, 75, 100, 150mm ADJUSTABLE

INNER DIAMETER OF BANDAGE ROLL: FROM 16mm TO 20mm, DEPENDS ON THE WIDTH OF BANDAGE ROLL. FOR 15CM WIDTH BANDAGE ROLL, THE INNER DIAMETER WILL BE 18mm (1.8CM)

PRODUCTION CAPACITY: THERE ARE 3 PRODUCTION TRACKS. EACH TRACK MAKES 5 TO 7 PCS OF BANDAGE ROLLS.

PRODUCTION CAPACITY CALCULATION: TO MAKE 15CM WIDE x 4 METER LONG BANDAGE ROLL IN ONE MINUTE, ONE TRACK MAKES 5 PCS TO 7 PCS BANDAGE ROLLS, SO, TOTAL CAPACITY IS 15 TO 21 PCS PER MINUTE BY 3 TRACKS. TO MAKE 4 METERS LENGTH x 10CM WIDTH GAUZE BANDAGE ROLL, YOU CAN MAKE 8 ROLLS PER TRACK PER MINUTE. SO, BY 3 TRACKS, YOU WILL MAKE 24 ROLLS PER MINUTE.

LENGTHWISE TOLERANCE OF READY-MADE BANDAGE ROLLS IS 3%. REGULARITY OF BOTH ENDS OF BANDAGE IS 2mm TO 3mm.

ELECTRICITY REQUIRED: 380V 50HZ 3PHASE AC OR 220V 60HZ 3PHASE AC.

RATED POWER: 3KW. H. COMPRESSED AIR PRESSURE REQUIRED30.5 MPA

LABOR: 1 PERSON

EQUIPMENT SIZE: 2200mm (L) x 1200mm (W) x 1800mm (H)

NET WEIGHT: 700KG