Description

FINAL COSMETIC COTTON PAD DIAMETER: 5.2 TO 5.5 CM CAN BE CUSTOMIZED

FLOW CHART: AUTOMATIC FEEDER → EMBOSSING ROLL → STAMPING AND SHAPING MACHINE→ ARRANGEMENT DISCHARGE

EQUIPMENT WITH STEEL ROLLER EMBOSSING DEVICE FOR HEATING A STEEL ROLLER SETS, ADJUST IF NECESSARY EMBOSSING CAN BE RAISED EMBOSSING ROLL WHEN NOT NEEDED TO ACHIEVE THE GOAL IS NOT EMBOSSED. (PATTERN CAN BE CUSTOMIZED ACCORDING TO CUSTOMER REQUIREMENTS)

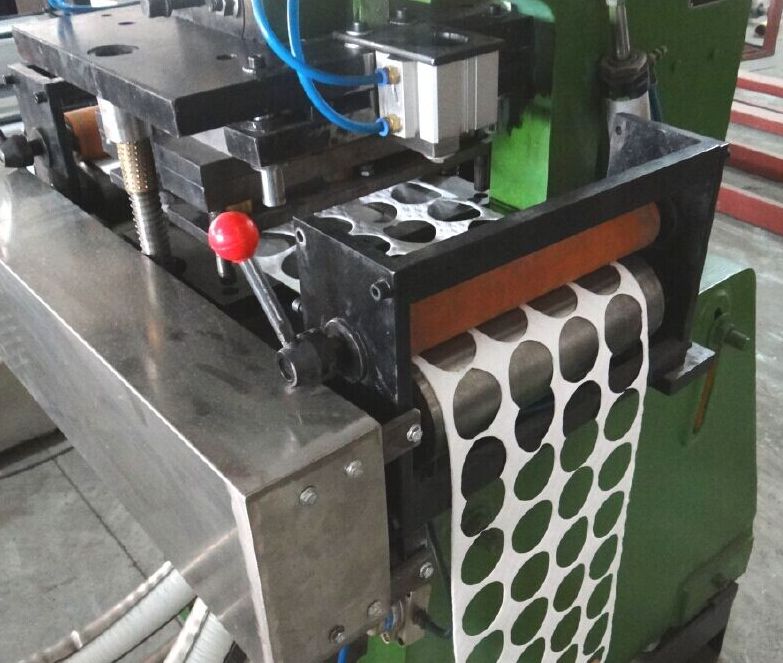

DEVICE IS EQUIPPED WITH A SET OF CIRCULAR CUTTER MOLD, MATERIALS ARE IMPORTED HIGH-QUALITY SPECIAL STEEL PRODUCTION, WHERE FOUR GROUPS OF CIRCULAR CUTTERS ARE SET AT REASONABLE DISLOCATION TYPE ARRANGEMENT, SO TO MINIMIZE THE AMOUNT OF MATERIAL LOSS, LOWERS THE RELATIVE COST AND IMPROVES THE PRODUCT EFFICIENCY.

DEVICE IS EQUIPPED WITH THREE ADJUSTABLE TENSION CONTROL DEVICES, IN ORDER TO ADAPT TO THE PRODUCTION OF VARIOUS MATERIALS.

PARTS OF THE TRANSMISSION EQUIPMENT CUTTER CAM MECHANICAL TRANSMISSION, ACCURATE PUNCHING, NO EDGES.

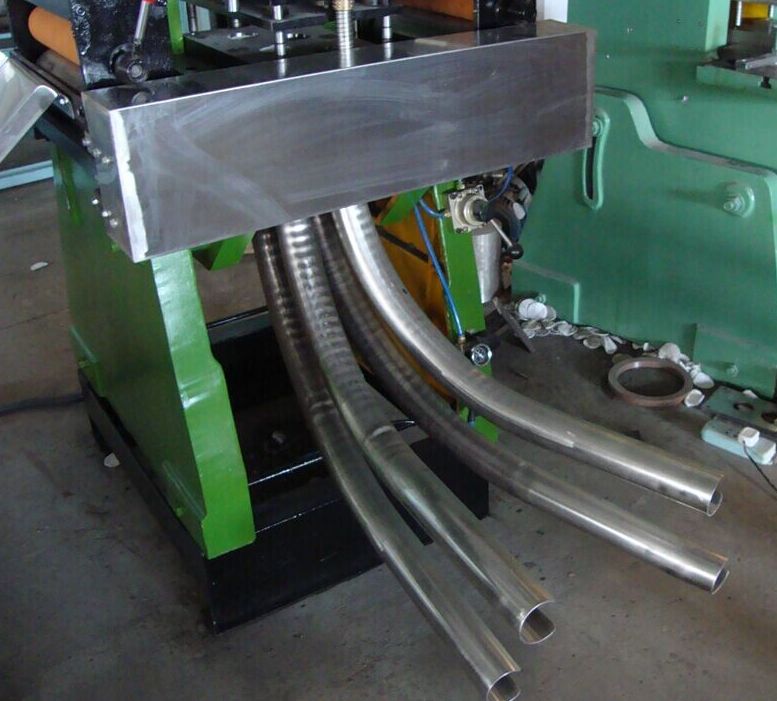

OVERALL USE OF INTERNATIONAL STANDARDS MOLDING STEEL FRAME, SURFACE TREATMENT FOR RUST FRAME SIZE, PRECISION WELDING, STANDARD PARTS SCREWS MAIN COMPONENTS OF DOMESTIC HIGH-QUALITY 45 # STEEL. COUNTERTOPS AND THE PRODUCT 304 STAINLESS STEEL FOR HEALTH PRODUCTS.

EQUIPMENT USING HIGH-PRECISION FREQUENCY INVERTERS AND RELATED ELECTRICAL CONTROLS

MACHINE TECHNICAL PARAMETER:

MODEL: M400

CAPACITY: 400PCS/MIN (4 PIECES/TIME)

VOLTAGE: AS PER CLIENTS REQUIREMENTS

RATE FREQUENCY: 50HZ

MOTOR: 5.5KW

OVERALL DIMENSION: 5000mm x 1000mm x 2000mm

MACHINE WEIGHT: 2300KG

QUANTITY: 1