Description

EFFECTIVE WIDTH: 1600mm

DAILY OUTPUT: 10,000 KGS PER DAY

WEIGHT RANGE: 10 TO 150 GSM

FILAMENT DIAMETER: 1.6 TO 2.0 DENIER

SPEED: 350 TO 400 METERS PER MINUTE

RAW MATERIAL: POLYPROPYLENE (PP)

DIMENSIONS: 35,000 X 15,000 X 11,000mm

VOLTAGE: 380 VOLTS, 3 PHASE

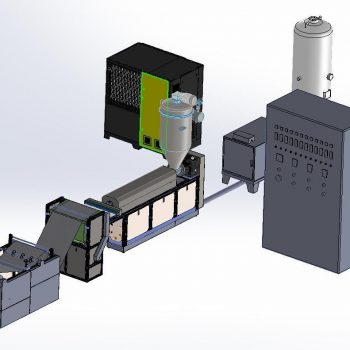

CONSISTING OF:

SPUNBOND EQUIPMENT

PP VACUUM SUCTION MACHINE (2)

7800 TO 900 KGS PER HOUR

AIR CAPACITY: 300 CUBIC METERS PER HOUR

POWER: 7.5 KW

MASTER BATCH DOSING UNIT (2)

ACCURACY: 0.01%

EXTRUDER (2)

DIAMETER: 130mm

SINGLE SCREW (2)

HEATING SYSTEM: ELECTRICITY

MOTOR: 75 KW

MELT FILTRATION MACHINE (2)

PIPE SIZE: 50mm

FILTER AREA: 3.5 SQUARE METERS

MELT FLOW: 650 KGS PER HOUR

DOUBLE FILTRATION CHAMBER

MELTING PUMP (2)

40 RPM

FLOW CAPACITY: 400 KGS PER HOUR

POWER: 7.5 KW

SPINNING BEAM (2)

DIMENSIONS: 1900 X 256mm

HANGER TYPE MELT DISTRIBUTION

HEATING SYSTEM: OIL

WORKING TEMPERATURE: 200 TO 260 CELSIUS

SPINNERET (4)

HARDNESS: 30

SIZE: 1900mm LONG X 256mm WIDE

HOLE DIAMETER 0.45mm

HOLE QUANTITY: 6500 HOLE PER METER

QUENCHING UNIT (2)

WORKING TEMP: 20 CELSIUS

AIR FLOW CAPACITY: 12,000 CUBIC METERS/H

AIR PRESSURE: 6500

FILTER SIZE: 80#

FILAMENT DRAFT UNITS (2)

AIR PRESSURE: 5020PA

AIR FLOW CAPACITY: 12,000 CUBIC METERS/H

INSIDE TEMP: 10 TO 25 CELSIUS

FILAMENT FINENESS: 1.6 TO 2.0 DENIER

MELT BLOWN EQUIPMENT

VACUUM SUCTION MACHINE (2)

LOAD CAPACITY: 700 TO 900 KGS PER HOUR

AIR CAPACITY: 300 CUBIC METERS/H

POWER: 7.5 KW

MASTER BATCH DOSING UNIT (2)

4 HOPPERS

200 KGS HOPPER LOAD

EXTRUDER

DIAMETER: 105mm

SINGLE SCREW

MOTOR: 18.5 KW

MELT FILTER

DOUBLE CYLINDER

HYDRAULIC

MELT FLOW CAPACITY: 450 KGS/HR

FILTER SIZE: 150mm DIAMETER

ELECTRIC HEATING

MELTING PUMP

SPEED: 40 RPM

MELT FLOW CAPACITY: 450 KGS PER HOUR

POWER: 7.5 KW

MELT BLOWN DIE SPINNARET

SPINNERET HOLE SIZE: 0.32 TO 0.35mm

HOLE DISTANCE: 40 TO 42 PER INCH

FABRIC WEIGHT: 2 TO 200 GSM

HIGH PRESSURE AIR BLOWER

AIR FLOW CAPACITY: 70 TO 100 CUBIC METERS PER MINUTE

AIR PRESSURE: 100 KPA

POWER: 200 KW

WEB FORMING MACHINE

SPEED: 100 METERS PER MINUTE

ELECTRIC TREATMENT

VOLTAGE: 220 VOLTS, 50 Hz

INPUT CURRENT: 3A

OUTPUT VOLTAGE: 60 KV

TREAT WEB WIDTH: 1.6 METERS

HOT AIR HEATING MACHINE

WORKING TEMP: 350 CELSIUS

PRESSURE: 0.8 KPA

HEATING: ELECTRIC

POWER: 200 KW

THERMAL CALENDER

PROCESSING SPEED: 400 METERS PER MINUTE

ROLLER SIZE: 2000mm LONG, 520mm DIAMETER

EMBOSSING ROLLER: 1

LINEAR PRESSURE: 30 TO 125 N/mm

HEATING SYSTEM: OIL

HYDROPHILIC MACHINE

SPEED: 400 METERS PER MINUTE

FEEDING SYSTEM: DOUBLE KISSING ROLLER

KISS ROLLER DIAMETER: 215mm

LIQUID TANK: 200 KGS WITH HEAT/WARM AND MIX

DRYING SYSTEM:

INFRARED + HOT AIR

DRIVE ROLL SIZE: 150mm

HEATING EQUIPMENT: QUARTZ HEATER, HOT AIR BLOWER, EXHAUST AIR BLOWER

INSPECTION MACHINE

EFFECTIVE WIDTH: 1600mm

INSPECTION SPEED: 400 METERS PER MINUTE

INSPECT GSM: 10 TO 40 GSM

AUTOMATIC WINDING MACHINE

SPEED: 400 METERS PER MINUTE

ROLLER DIAMETER: 2000mm

ROLLER EXCHANGE SYSTEM: AUTOMATIC

FABRIC INSPECTOR: ONLINE

POWER: 15 KW

HIGH SPEED SLITTING MACHINE

PROCESS SPEED: 800 METERS PER MIN

ROLL DIAMETER: MAX 1500mm

SLITTING WIDTH: 80mm

PAPER TUBE SIZE: 76mm DIAMETER

AUTO TENSILE CONTROL: AVAILABLE ONLINE

METER COUNTING: AVAILABLE ONLINE

OIL HEATER (4)

HEATING POWER: 60 KW

MOTOR POWER: 7.5 KW

OIL PUMP FLOW: 30 CUBIC METERS PER SECOND

PRESSURE: 0.4 KPA

WATER CHILLER

DRIVE SYSTEM: SCREW

COOLING CAPACITY: 300,000 CALORIES

TEMP: 0 TO 20 CELSIUS

POWER: 110 KW

AIR BLOWER

SPEED: 1450 RPM

AIR BLOW CAPACITY: 12,000 CUBIC METERS PER HOUR

PRESSURE: 5200 PA

POWER: 30 KW x 3, 45 KW x 1

AIR COMPRESSOR

DRIVE SYSTEM: SCREW

PRESSURE: 0.8 KPA

POWER: 15 KW

HEATING SYSTEM: ELECTRIC

TEMP: 350 CELSIUS

HEATING TIME: 6 TO 8 HOURS

POWER: 4 KW

ULTRASONIC CLEANING MACHINE

3mm THICK

SIZE: 2000 X 500mm

FREQUENCY VIBRATION: 100 KHZ

TEMP: 40 CELSIUS

ELECTRONIC PANEL BOARD

PLATFORM