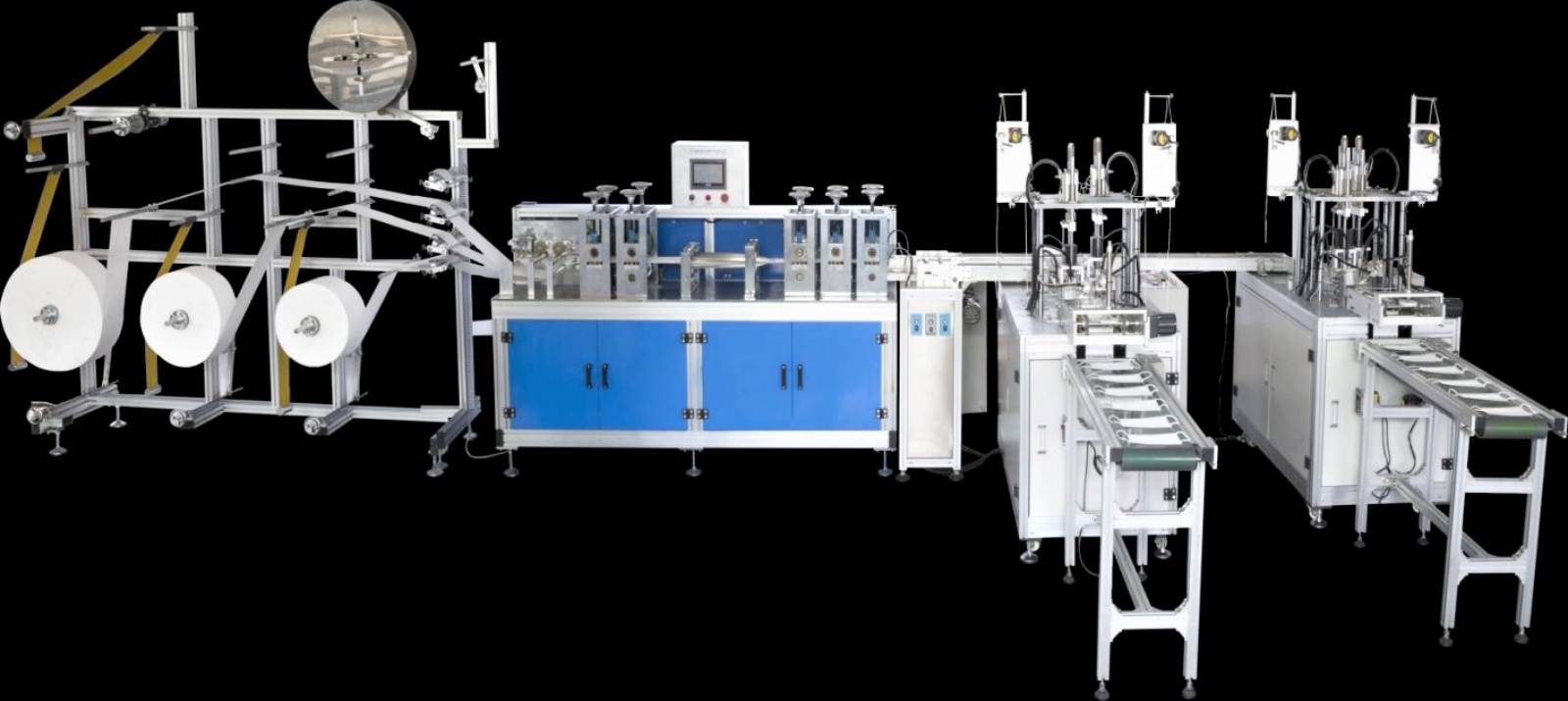

Description

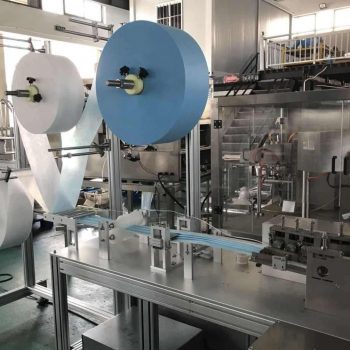

PRODUCTION CAPACITY: 120 TO 165 PIECES PER MINUTE

FOR MASKS WITH 3 TO 4 LAYERS OF NONWOVEN MATERIAL

WITH ADJUSTABLE MASK DIMENSIONS: 130 TO 185mm LONG AND 80 TO 110mm WIDE

WITH ADJUSTABLE NOSE-LINE LENGTH

OPERATIONS CONTROLLED BY PLC

MOTOR HAS MAGNETIC WHEEL WITH BRAKING FUNCTION

MACHINE FRAME CONSTRUCTED OF ALUMINUM

TOTAL POWER: 8 KW

VOLTAGE: 220 VOLTS, 50 Hz (OR AS PER CUSTOMER)

MACHINE WEIGHT: 1600 KG

AIR PRESSURE REQUIRED: 0.6 mpa

GROUND LOAD: ≤ 500 kgmm2

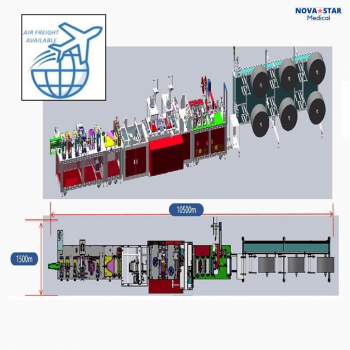

MAIN UNIT DIMENSIONS: L 2100 x W 600 x H 1200mm

DISCHARGE RACK DIMENSIONS: L 1700 x W 600 x H 1400mm

CONVEYOR BELT DIMENSIONS: L 2800 x W 350 x H 910mm

PRODUCTION FLOW

MULTI-STATION LOADING

MATERIAL FEEDING

MAIN BODY DRAPING

NOSE BRIDGE BAR INSERTION

ULTRASONIC WELDING

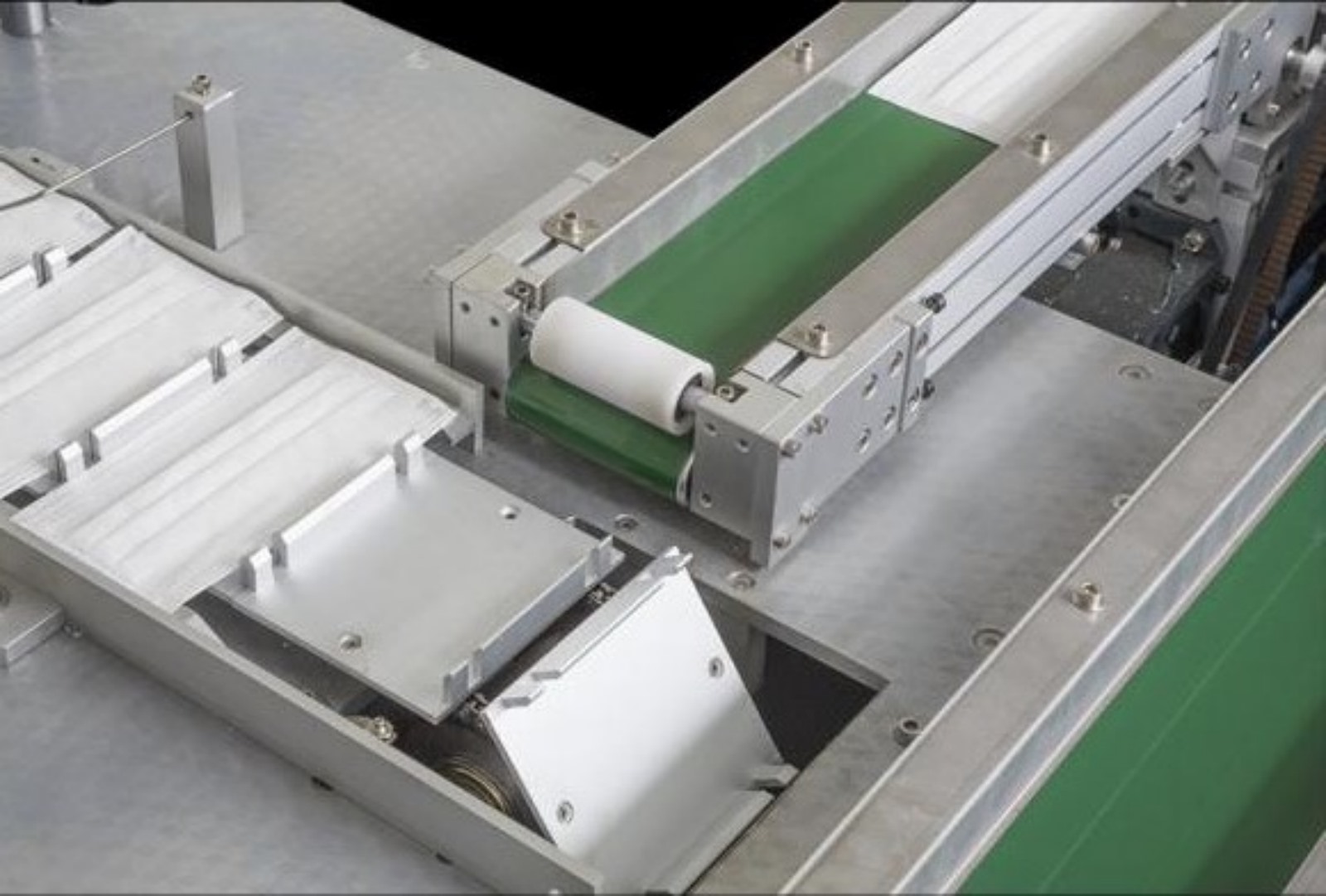

1:2 DISTRIBUTION (SPLITS MASKS INTO TWO LANES)

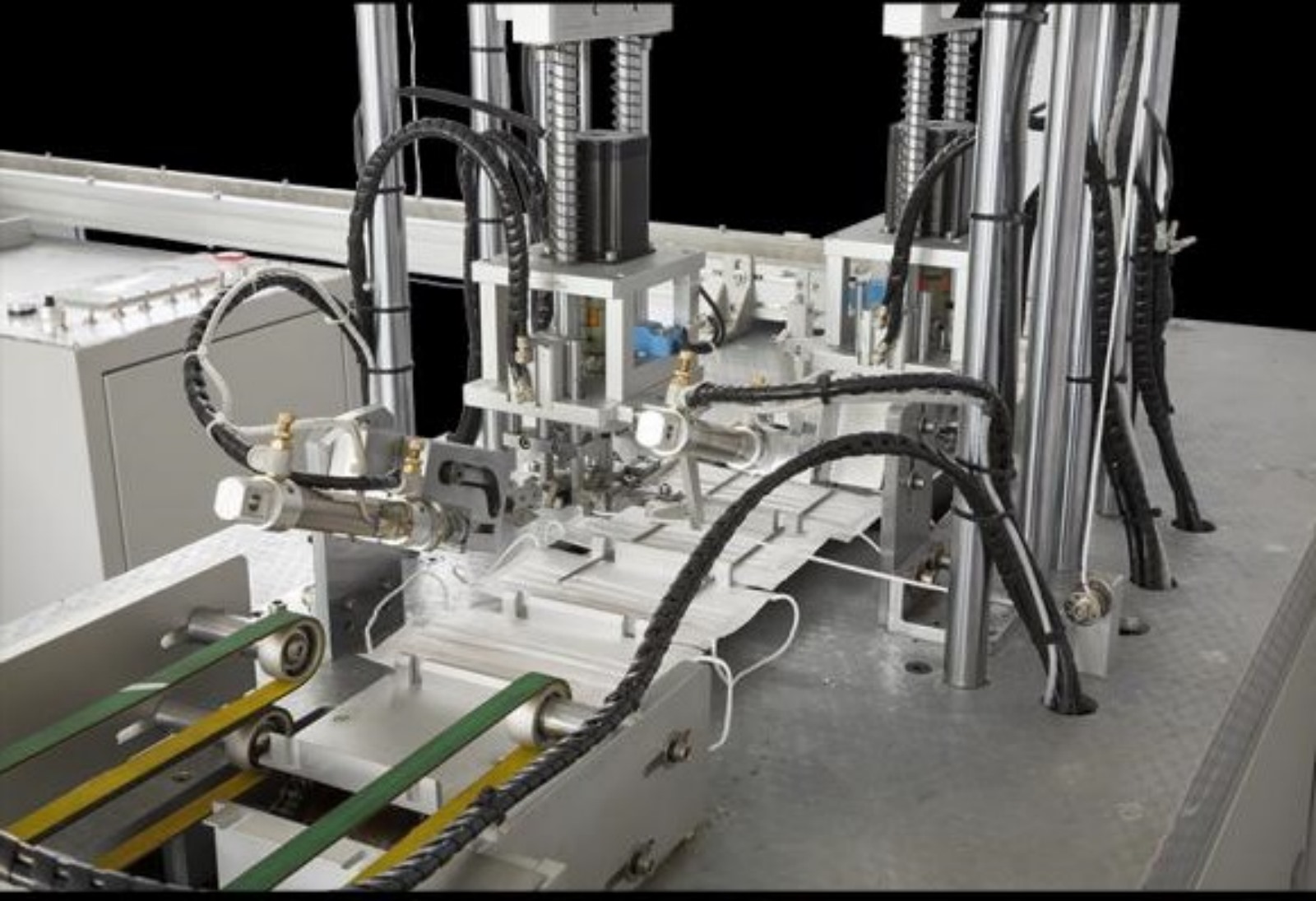

EAR LOOP WELDING (EACH LANE)

AUTOMATIC STACKING OF FINISHED MASKS

OPERATION

1. PLACE RAW MATERIALS ON RAW MATERIALS RACK

2. RAW MATERIALS ENTER MACHINE

3. MACHINE PERFORMS EDGE CORRECTION TO ENSURE PROPER ULTRASONIC WELDING

4. MACHINE EVENLY FOLDS MATERIAL INTO ACCORDION SURFACE (3 FOLDS)

5. FOLDED MASKS ARE THEN ULTRASONICALLY WELDED AND CUT AT THE ROLLER STATION

6. MASKS MOVE ALONG SHUNT AND CONVEYOR BELT TO CORRESPONDING EAR LOOP WELDING STATION

7. SPOT WELDING MACHINE RECEIVES THE MASK BODY AND FEEDS IT INTO THE MOLD WHILE WELDING THE EAR LOOPS TO THE BODY OF THE MASK

8. SPOT WELDING MACHINE SENDS COMPLETED MASK TO COLLECTOR/STACKER (PROGRAMMABLE TO SET NUMBER OF MASKS PER GROUP) AND THEN MASKS EXIT MACHINE ON CONVEYOR BELT

COMPONENT LIST AVAILABLE, PLEASE INQUIRE

LEAD TIME: 35 DAYS FROM RECEIPT OF DEPOSIT

QUANTITY: 1 COMPLETE PRODUCTION MACHINE