Description

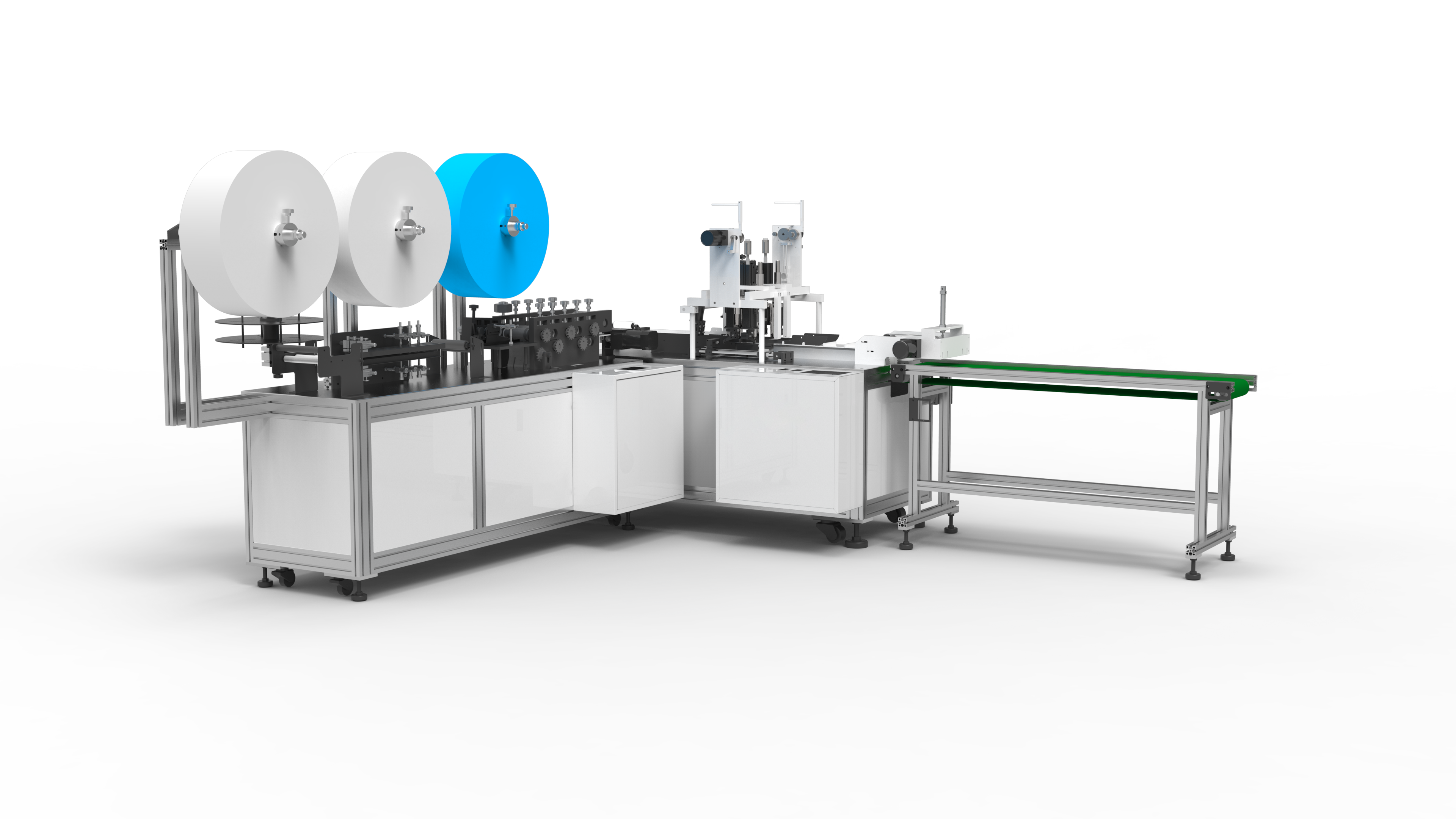

AUTOMATIC LINE FOR THE PRODUCTION OF FACE MASKS

CAPACITY: 100 TO 120 PIECES PER MINUTE

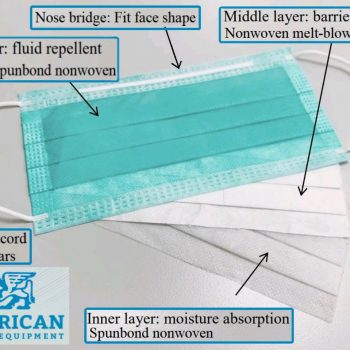

MASK DIMENSIONS: 175 x 95mm

SERVO MOTOR DRIVEN EAR LOOP MACHINE

PLC CONTROLLED FOR EASY OPERATIONS

CE COMPLIANT, WITH CERTIFICATE

MATERIAL SPECIFICATIONS

| ITEM | NUMBER OF HANGING SHAFTS | WIDTH (mm) | COIL OUTSIDE DIAMETER (mm) | INNER DIAMETER OF BARREL (mm) | WEIGHT |

| NON-WOVEN MELT BLOWN CLOTH | 3 | 170 TO 200 | Ø600 | Ø76.2 | 15 KG MAXIMUM |

| NOSE BRIDGE STEEL WIRE COVERED PLASTIC / PURE STEEL | 1 | 3 TO 7 | Ø400 | Ø76.2 | 25 KG MAXIMUM |

| EAR BELT | 2 BAGS | 160 x 3 | – | – | 10N |

LINE COMPOSED OF

WATER FILTER CLOTH / FILTER COTTON / WATER ABSORPTION LAYER UNWINDING – 3 SETS (UP TO 4)

NOSE BRIDGE STRIP UNWINDER – 1 SET

NOSE BRIDGE STRAIGHTENER – 1

NOSE BRIDGE STRIP DRIVING AND CUTTING MECHANISM – 1

FABRIC HEMMING MECHANISM – 1

ROLL WELDING EDGE SEALING MECHANISM – 1 (BOTH SIDES)

CLOTH DRIVING MECHANISM – 1

CLOTH FAN FOLDING MECHANISM – 1

SIDE SEAM ROLL WELDING MECHANISM – 1 (NEEDED FOR FULLY AUTOMATED MACHINE)

ROLL-SEALING MECHANIM – 1 (LAMINATED)

SHUNTING MECHANISM (SLICING MACHINE) – 1 (NEEDED FOR FULLY AUTOMATED MACHINE)

EAR BAND WELDING MACHINE – 1

BLANKING LINE (LAMINATED LINE) – 2

OPERATION PANEL – 1

EFFICIENCY RATING: 99%

FAILURE RATE: 2%

POWER CONSUMPTION: ~8.5 KW

WORKING POWER: 220 VOLTS, 50 OR 60 Hz

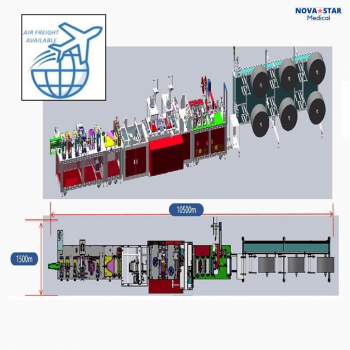

DIMENSIONS: 5000mm L x 3500mm W x 1800mm H

COMPONENTS USED

CYLINDER: AIRTAC, CHELIC TAIWAN

ELECTROMAGNETIC VALVE: AIRTAC, CHELIC

SERVO MOTOR: TOPSTAR/CHINA, YASKAWA/JAPAN, DELTA/TAIWAN

PLC: OMRON JAPAN, MITSUBISHI JAPAN, DELTA TAIWAN

BEARINGS: NSK JAPAN, SAMICK KOREA

RAIL LINE: THK, PMI, CPC TAIWAN

OPTICAL FIBER, MAGNIFYING GLASS: OMRON, KEYENCE, PANASONIC JAPAN

TOUCH SCREEN: WEINVIEW/TONTAI

RELAY: OMRON/IDEC

BUTTONS: HBAN

DELIVERY TIME: 25 DAYS FROM RECEIPT OF ORDER TO SHIP

QUANTITY: 1 COMPLETE LINE