Description

|

SPECIFICATION |

DIMENSIONS OF THE WORKING CHAMBER:1140 × 400 × 380 mm

OUTER DIMENSION: 1300 × 500 × 1460 mm CENTRE DISTANCE OF LIGHT: 70 mm CLOSEST PARALLEL PLANE DISTANCE FROM TEST SPECIMEN TO LIGHT SURFACE: ABOUT 50 mm WAVELENGTH RANGE: UV-A WAVELENGTH RANGE: 315 TO 400 NM / UV-B WAVELENGTH RANGE 290 TO 313 NM RADIATION INTENSITY:1.5 W /M2 /340 NM TEMPERATURE RESOLUTION: 0.1 ℃ LUMINOUS TEMPERATURE RANGE: 50 ℃ TO 70 ℃ /TEMPERATURE TOLERANCE ±3 ℃ CONDENSATION TEMPERATURE RANGE: 40℃ TO 60 ℃ /TEMPERATURE TOLERANCE ± 3 ℃ BLACKBOARD THERMOMETER MEASURING RANGE: 30 TO 80 ℃ /TOLERANCE ± 1 ℃ TEMPERATURE CONTROL TYPE: PID SELF SETTING TEMPERATURE CONTROL MODE HUMIDITY RANGE: ABOUT 45% TO 70% R.H (ILLUMINATION CONDITION) / ABOVE 98% (CONDENSATION STATUS) SINK REQUIREMENTS: WATER MAXIMUM DEPTH IS 25 mm THERE IS AN AUTOMATIC WATER SUPPLY CONTROLLER STANDARD SPECIMEN SIZE: 75 × 150 mm 48 PCS RECOMMENDED ENVIRONMENT FOR INSTRUMENT USE: 5 TO 35 ℃, 40% TO 85% R·H, DISTANCE TO THE WALL 300 mm |

|

MAIN FUNCTION |

THIS ULTRAVIOLET RAY ACCELERATED AGING, TEST CHAMBER ILLUMINANT USE IMPORTED UVA-340 FLUORESCENT UV LAMP. CAN SIMULATE HARM BY SUNLIGHT, RAINWATER AND RAINWATER. UV WEATHER RESISTANCE CHAMBER USE FLUORESCENT UV LAMP ILLUMINANT EFFECT OF SUNLIGHT, CONDENSATION MOISTURE IS USED TO SIMULATE DEW. TESTED MATERIAL PUT IT UNDER LIGHT AT A CERTAIN TEMPERATURE TEST THE CYCLE OF ALTERNATING MOISTURE AND HUMIDITY THE MATERIAL WAS TESTED FOR ACCELERATED ATMOSPHERIC EXPOSURE TEST,UV CHAMBER. IT TAKES DAYS OR WEEKS. REAPPEAR MONTH OR YEARS OF DAMAGE. THE TYPES OF HAZARDS INCLUDE: COLOUR FADING, COLOR CHANGE, GLOSS LOSE, CRACKING, MUDDY, BUBBLE, EMBRITTLEMENT, INTENSION, RECESSION AND OXIDATION ETC.THIS MACHINE INCLUDES SPRAY DEVICE.

UV ACCELERATED AGING TEST CHAMBER CAN SIMULATE THE NATURAL CLIMATE ULTRAVIOLET、RAIN、HIGH TEMPERATURE, HIGH HUMIDITY, CONDENSATION, DARKNESS ETC ENVIRONMENTAL CONDITIONS,BY REPRODUCING THESE CONDITIONS,MERGE INTO A CYCLE , LET IT AUTOMATICALLY EXECUTE THE NUMBER OF COMPLETED CYCLE. WORKING PRINCIPLE OF UV AGING TEST CHAMBER. IN THIS PROCESS,THE DEVICE CAN BE APPLIED TO THE BLACKBOARD TEMPERATURE, SINK TEMPERATURE AUTOMATIC MONITORING: BY CONFIGURING IRRADIANCEMEASURING AND CONTROL DEVICE(OPTIONAL),IRRADIANCE CAN BE MEASURED AND CONTROLLED, IRRADIATION STABILITY AT 0.76 W / M2 / 340 NM OR SPECIFIES A SET VALUE,AND GREATLY EXTEND THE SERVICE LIFE OF THE LAMP |

| COMPLY WITH INTERNATIONAL STANDARDS | ASTM G 153, ASTM G 154, ASTM D 4329, ASTM D 4799,ASTM D 4587, SA E,J2020, ISO 4892 ALL CURRENT UV AGING TEST STANDARDS |

| SUBENTRY INTRODUCE | |

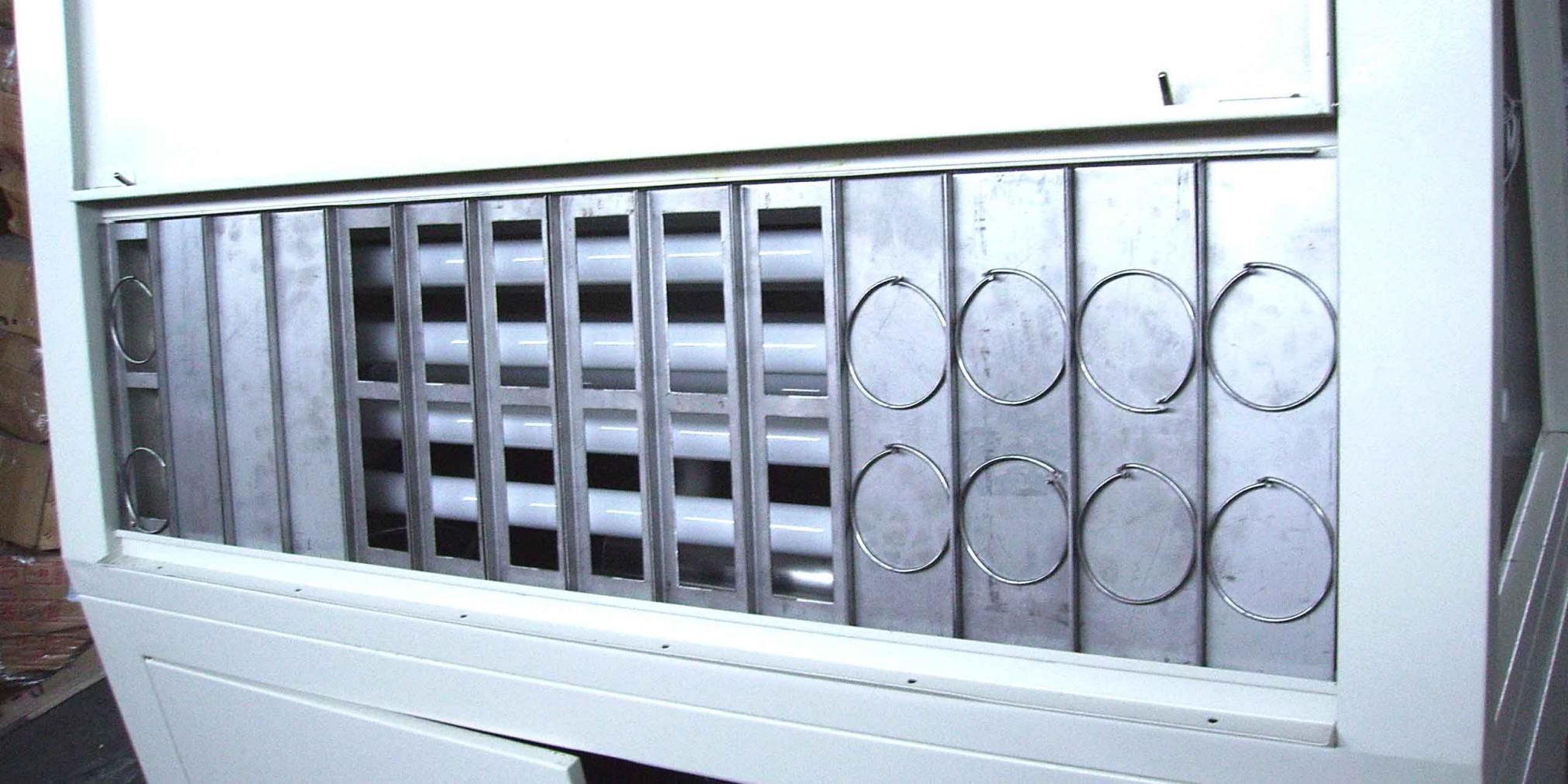

| LIGHT SOURCE INCORPORATES 8 PCS 40 W RATED POWER UV FLUORESCENT LAMP AS LUMINOUS SOURCE.UV FLUORESCENT TUBE,DISTRIBUTED ON BOTH SIDES OF THE MACHINE,EACH SIDE 4 PCS.UVA-340 AND UVB-313LUMINOUS SOURCE FOR USER OPTIONAL CONFIGURATION.UVA-340 LUMINOUS SPECTRAL ENERGY OF A LAMP TUBE MAIN FOCUS ON 340 NM WAVE LENGTH, LAMP TUBE SPECTRUM FOCUS AROUND UVB-313 WAVE LENGTH. WE USE UVA-340 TUBE.FLUORESCENT LIGHT ENERGY OUTPUT DECLINE WITH TIME,TO REDUCE EFFECT BY LIGHT ENERGY ATTENUATION. TEST CHAMBER OF EVERY 1/4 FLUORESCENT LAMP LIFE TIME, CONSIST OF A NEW TUBE REPLACING AN OLD TUBE. ULTRAVIOLET SOURCE CONSIST OF NEW TUBE AND OLD TUBE,GET CONSTANT LIGHT ENERGY OUTPUT. LAMP TUBE EFFECTIVE SERVICE LIFE IS ABOUT 1600 HOURS | |

|

POWER-SUPPLY CONTROL |

A. THE BOARD TEMPERATURE、CONDENSING TEMPERATURE CONTROL WITH CONTROLLER

B. THE REST ARE IMPORTED ELECTRONIC COMPONENTS IRRADIANCE UNIFORMITY: ≤ 4%(AT THE SURFACE OF THE SAMPLE) BLACKBOARD TEMPERATURE MONITORING: USE STANDARD PT-100 BLACKBOARD TEMPERATURE SENSOR, ACCURATE CONTROL OF THE SAMPLE SURFACE TEMPERATURE DURING THE TEST PROCESS BLACKBOARD TEMPERATURE SETTING RANGE: BPT 40 TO 75℃: BUT THE TEMPERATURE PROTECTION INSIDE THE MACHINE ACTUAL MAX TEMPERATURE IS 93 ℃ ± 10%. BLACKBOARD TEMPERATURE CONTROL ACCURACY: ± 0.5 ℃, C、TANK TEMPERATURE MONITORING: DURING THE CIRCLE TEST, THERE’S A TEST SECTION IS DARK CONDENSATION PROCESS,IT REQUIRES HIGH TEMPERATURE SATURATED STEAM INSIDE THE CHAMBER,WHEN THE STEAM HITS A RELATIVELY COLD SURFACE OF THE SAMPLE,DEW WILL CONDENSE ON THE SURFACE OF THE SAMPLE. THE TANK IS LOCATED AT THE BOTTOM OF THE CHAMBER, BUILT-IN ELECTRIC HEATER. TANK TEMPERATURE CONTROL RANGE: 40 TO 60 ℃ D、THE TEST CHAMBER IS EQUIPPED WITH A TIME CONTROLLER,RANGE 0 TO 530 H,BACKUP DATA FOR POWER FAIL E、SAFETY PROTECTION EQUIPMENT: ◆ OVER TEMPERATURE PROTECTION IN CHAMBER: WHEN TEMPERATURE EXCEED 3 ℃ ± 10% IN CHAMBER,THE MACHINE WILL AUTOMATICALLY CUT OFF THE SUPPLY OF THE LAMP AND HEATER,AND GO INTO EQUILIBRIUM STATE COOLING ◆ LOW WATER TANK ALARM,PREVENT HEATER FROM BURNING |

|

CHAMBER MATERIAL: |

◆ INNER CONTAINER USE SUS304# STAINLESS STEEL PLATE

◆ OUTER SHELL USE SUS304# STAINLESS STEEL PLATE ◆ SPECIMEN FRAME USE STAINLESS STEEL AND ALUMINUM ALLOY NET FRAME,EASY ACCESS TO SAMPLES |

| WHOLE INSTRUMENT PROFILE | ◆ DIMENSION: ABOUT 1370 × 1350 × 530 mm

◆ WEIGHT ABOUT 150 KG |

|

MAIN FRAME WORKING ENVIRONMENT |

◆ POWER REQUIREMENT: 220 VOLTZ AND 50/60 Hz

◆ ENVIRONMENT: 5 TO 35 ℃,0 TO 80% RH,GOOD VENTILATION, INDOOR ENVIRONMENT CLEANING ◆ AREA OF WORK ABOUT 234 × 353 CM ◆ WATER DRAINING: A DRAIN IS NEEDED ON THE FLOOR NEAR THE MAIN ENGINE ◆ EASE MOVEMENT, FOOT WHEEL IS INSTALLED AT THE BOTTOM OF THE INSTRUMENT, AFTER THE POSITION IS FIXED, THE POSITION OF THE TEST MACHINE IS FIXED WITH A U-RING |

| CONTROL METE | THE DEVICE USE A TRUE COLOR TOUCH SCREEN,PID TEMPERATURE INTELLIGENT CONTROL DEVICE,HIGH PRECISION TEMPERATURE CONTROL AND GOOD STABILITY |

|

INSTALLATION SITE: |

FOR THE CONVENIENCE OF HEAT DISSIPATION AND MAINTENANCE,THE INSTALLATION OF THE EQUIPMENT MUST MEET THE FOLLOWING CONDITIONS:

1. ADEQUATE MAINTENANCE SPACE SHOULD BE MAINTAINED BETWEEN THE EQUIPMENT AND WALLS OR OTHER EQUIPMENT AFTER INSTALLATION AND ADJUSTMENT. 2. IN ORDER TO STABILIZE OPERATE THE FUNCTION OF TEST EQUIPMENT、PERFORMANCE, TEMPERATURE SHOULD BE CHOSEN IS 15 ℃ TO 28℃,RELATIVE HUMIDITY MAX 85% OF THE PLACE: 3. THE ENVIRONMENTAL TEMPERATURE OF THE INSTALLATION SITE SHOULD NOT CHANGE SHARPLY: 4. IT SHOULD BE INSTALLED ON HORIZONTAL GROUND(USE A LEVEL METER TO CONFIRM THE LEVEL ON THE GROUND DURING INSTALLATION): 5. IT SHOULD BE INSTALLED IN PLACES WITHOUT DIRECT SUNLIGHT: 6. IT SHOULD BE INSTALLED IN A WELL-VENTILATED PLACE; 7. SHOULD BE INSTALLED AWAY FROM COMBUSTIBLE MATERIALS, EXPLOSIVE ANDHIGH TEMPERATURE SOURCE; 8. IT SHOULD BE INSTALLED IN A LITTLE DUSTY PLACE 9. INSTALL CLOSE TO THE POWER SOURCE |

|

STRUCTURE PROFILE |

EQUIPMENT SHELL AND INNER ROOM ARE SELECTED HIGH QUALITY SUS304,THE MOST ADVANCED PROCESSING EQUIPMENT IN CHINA IS USED FOR PROCESSING AND FORMING,THE SURFACE OF THE SHELL IS SPRAYED WITH PLASTIC,BEAUTIFUL,SMOOTH。 COLOR COORDINATION,SMOOTH LINE. THE DEFECTS OF SURFACE DAMAGE CAUSED BY ALUMINUM PLATE SURFACE SPRAYING ARE AVOIDED. THE EQUIPMENT WORKSHOP IS EQUIPPED WITH A HUMIDIFYING HEATER, LIQUID LEVEL SWITCH, BLACKBOARD TEMPERATURE SENSOR ETC,IT ALSO HAS EIGHT ULTRAVIOLET RADIATION FLUORESCENTS AND BIOSTERITRON (OPTIONAL). HIGH QUALITY IMMOVABLE PU WHEEL IS INSTALLED AT THE BOTTOM OF THE MACHINE, THE MACHINE CAN BE MOVED TO THE SPECIFIED LOCATION EASILY. FINALLY, THE CASTER IS FIXED |

|

NOTES |

1. DURING THE OPERATION OF THE EQUIPMENT, ADEQUATE WATER SUPPLY MUST BE MAINTAINED:

2. THE OPENING TIME OF THE DOOR SHOULD BE MINIMIZED DURING THE TEST PERIOD: 3. NON-FULL-TIME OPERATORS SHALL NOT OPERATE: 4. WHEN THE DEVICE IS UNABLE TO TROUBLESHOOT ITSELF,PLEASE CONTACT US 5. AFTER STOP USE FOR A LONG PERIOD,IF NEED TO USE AGAIN, THE WATER SOURCE MUST BE CAREFULLY EXAMINED、POWER SUPPLY AND COMPONENTS,DO NOT START THE DEVICE UNTIL YOU ARE SURE IT IS CORRECT: BECAUSE OF ULTRAVIOLET RADIATION EXIST STRONG HARM ON PEOPLE(ESPECIALLY THE EYES), SO OPERATORS SHOULD MINIMIZE EXPOSURE TO UV RADIATION(CONTACT TIME < 1 min). |

|

MAINTENANCE ,EXAMINE |

1. KEEP THE APPEARANCE OF THE CHAMBER CLEAN; AVOID DUST INTRUSION INTO THE CHAMBER

2. AVOID EXTERNAL FORCE HITTING THE CHAMBER 3. NO CHEMICALS ARE ALLOWED TO TOUCH THE EQUIPMENT 4. THE LABORATORY MAINTAINS A DRY ENVIRONMENT 5. IT IS ABSOLUTELY PROHIBITED TO SET THE TEMPERATURE ABOVE THE MAXIMUM TEMPERATURE SPECIFIED BY THIS EQUIPMENT 6. HECK THE CIRCUIT CONTROL SYSTEM BEFORE STARTING UP 7. POWER AND GROUND WIRE CONFIRMATION; 8. WHETHER THE POWER CORD IS PROPERLY CONNECTED ACCORDING TO THE SPECIFICATIONS,AND INDEED GROUNDED 9. CHECK THE OVERTEMPERATURE PROTECTOR(ADJUSTED WHEN LEAVING THE FACTORY. GENERALLY, NO ADJUSTMENT IS REQUIRED) 10. VENTILATOR SHOULD BE INSTALLED IN THE LABORATORY,MAINTAIN INDOOR VENTILATION 11. THE WATER LEVEL OF THE WATER TANK SHOULD BE OBSERVED DURING THE SPRAY TEST,REPLENISH TAP WATER IN TIME 12. THE EQUIPMENT’S WASTE WATER DISCHARGE SYSTEM MUST BE INSTALLED IN PLACE 13. AFTER THE TEST, CUT OFF THE POWER SUPPLY OF THE WHOLE MACHINE 14. AFTER EACH TEST, THE SAMPLE SHOULD BE TAKEN OUT AND THE EQUIPMENT TANK CLEANED 15. NON – PROFESSIONALS ARE STRICTLY PROHIBITED FROM OPERATING THE EQUIPMENT. |