Description

SPECIFICATIONS:

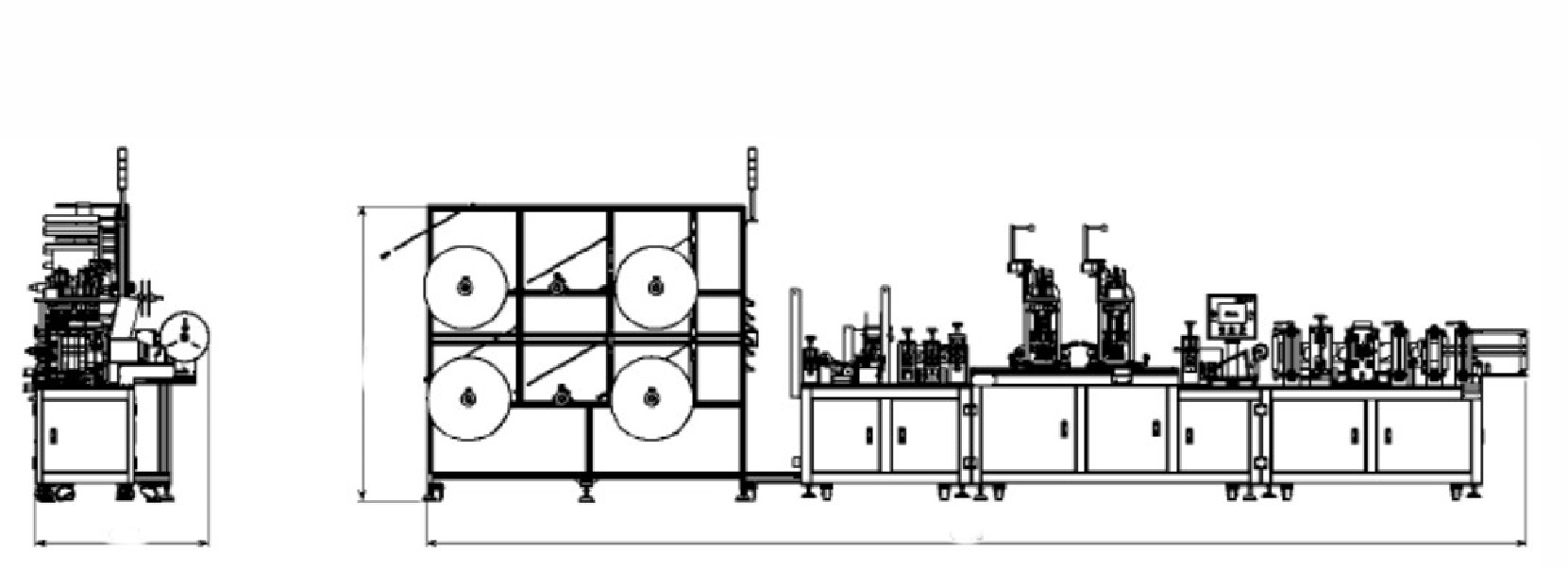

OVERALL: 9000 X 1500 X 2200 mm

WEIGHT: 6000 KG

TOTAL POWER: 10 KW, 220 VOLTZ AND 50/60 Hz OR CUSTOMIZED

AIR PRESSURE: 5 TO 8 BAR (0.5 MPA TO 0.8 MPA)

PRODUCTIVITY: 40 TO 50 PCS/Min

CONTROL SYSTEM: PLC WITH SERVO SYSTEM

ELECTRICAL COMPONENTS: SCHNEIDER®, OMRON® OR EQUIVALENT

PNEUMATIC COMPONENTS: AIRTAC® OR EQUIVALENT

TYPE: AUTOMATIC KN95 FACE MASK MAKING MACHINE

FEATURES:

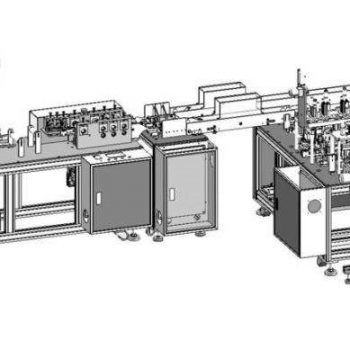

FULLY AUTOMATIC N95 PRODUCTION LINE

• ALUMINUM ALLOY FRAME, STEADY AND NEAT, FAST TO SET UP

• COMPACT DESIGN, LESS SPACE INVESTMENT

• INDIVIDUAL DETECT SENSOR FOR EACH STATION, STATUS MONITOR ON TOUCH SCREEN, FAST DEBUG IF THE MACHINE FAILURE

• HIGH QUALITY ELECTRICAL COMPONENTS AND PNEUMATIC COMPONENTS

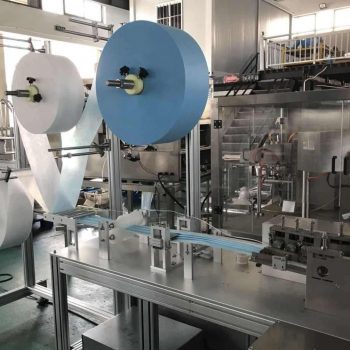

MATERIAL FEEDING SYSTEM

• 4 TO 6 ROLLS MATERIAL ARE ACCEPTABLE

• INDIVIDUAL UNCOIL TENSION CONTROL

• MATERIAL DETECTION SENSOR FOR EACH ROLL

NOSE WIRE FEEDING UNIT

• AUTO FEEDING, CUTTING AND STRAIGHT

• FIRST WELDING STATION

• COMPACT DESIGN, NOSE WIRE WELDING AND INITIAL WELDING

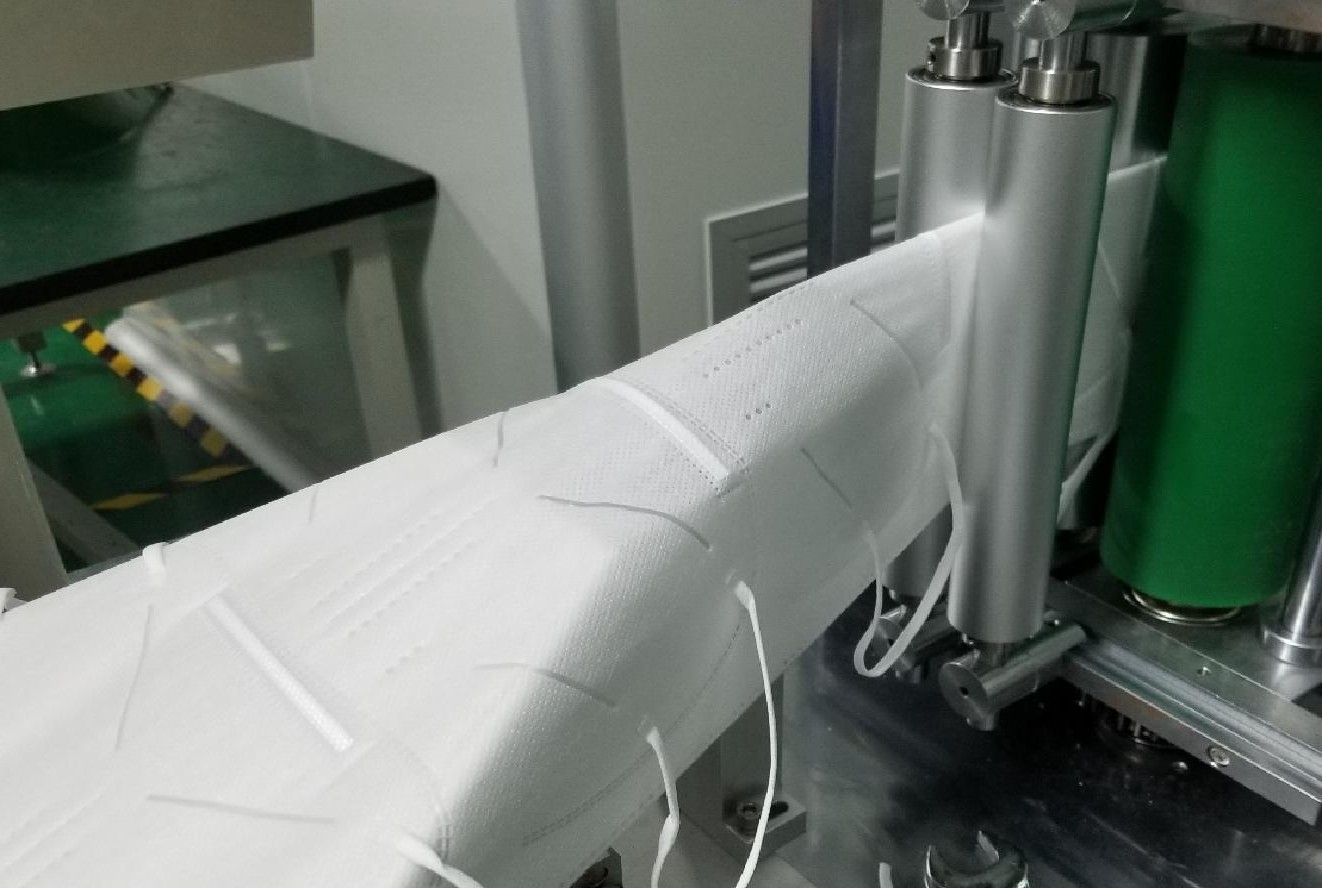

FLYER EAR LOOP WELDING SYSTEM

• UNINTERRUPTED FLYER EAR LOOP WELDING

• DOUBLE SIDE EFFICIENT WELDING DESIGN

FOLDING UNIT

• CONTINUOUS FOLDING DEVICE, SMART FIT TO PRODUCTION SPEED

SECOND FLYER WELDING STATION

• UNINTERRUPTED FLYER EDGE WELDING

CUTTING DEVICE

• UNINTERRUPTED CUTTING

WASTE COLLECTOR

• CONTINUOUS COLLECT