Description

SPECIFICATION:

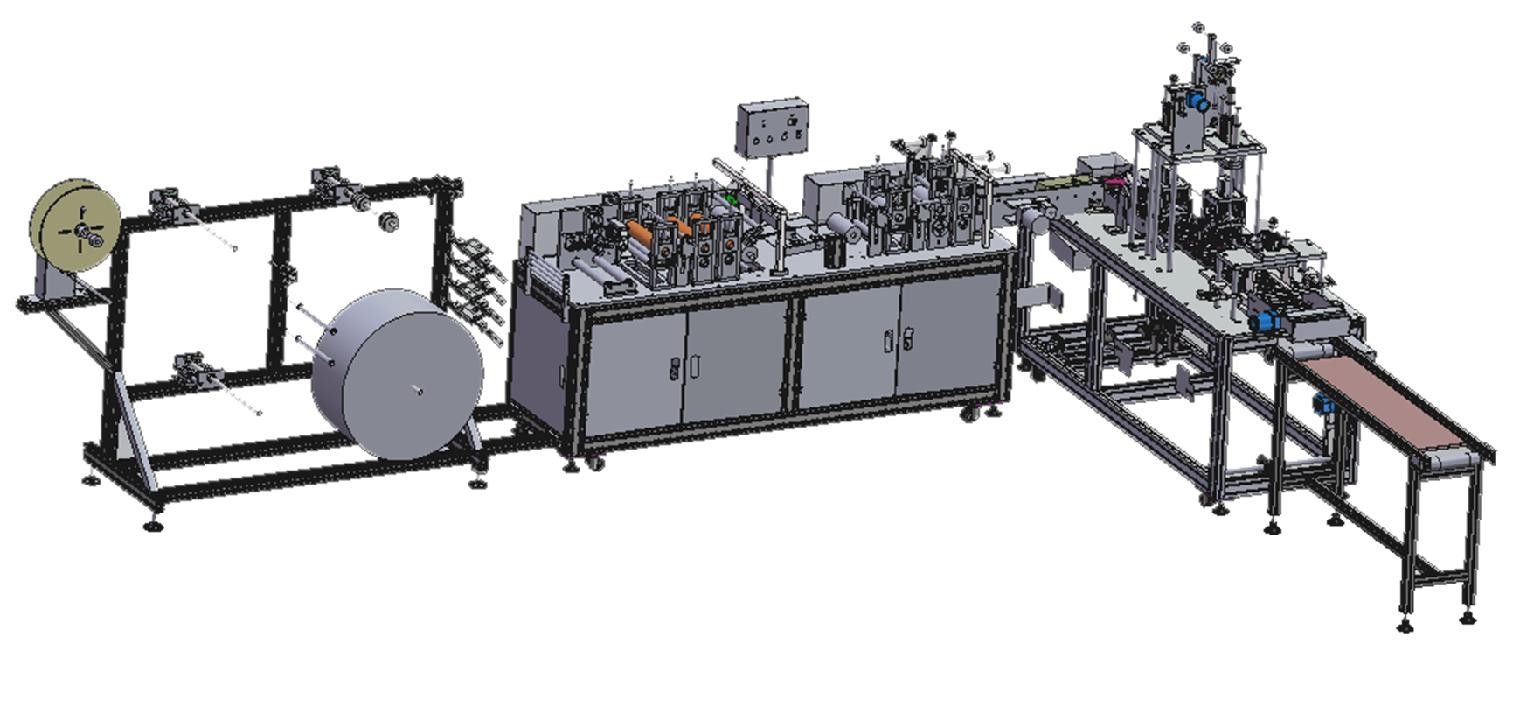

OVERALL: 5700 X 4500 1900 mm

WEIGHT: 1500 KG

TOTAL POWER: 7.5 KW, 220 VOLTZ AND 50/60 Hz OR CUSTOMIZED

AIR PRESSURE: 6 BAR

PRODUCTIVITY: 50 TO 60 PCS/Min

CONTROL SYSTEM: A. MITSUBISHI® PLC WITH FULL COLOR TOUCH SCREEN

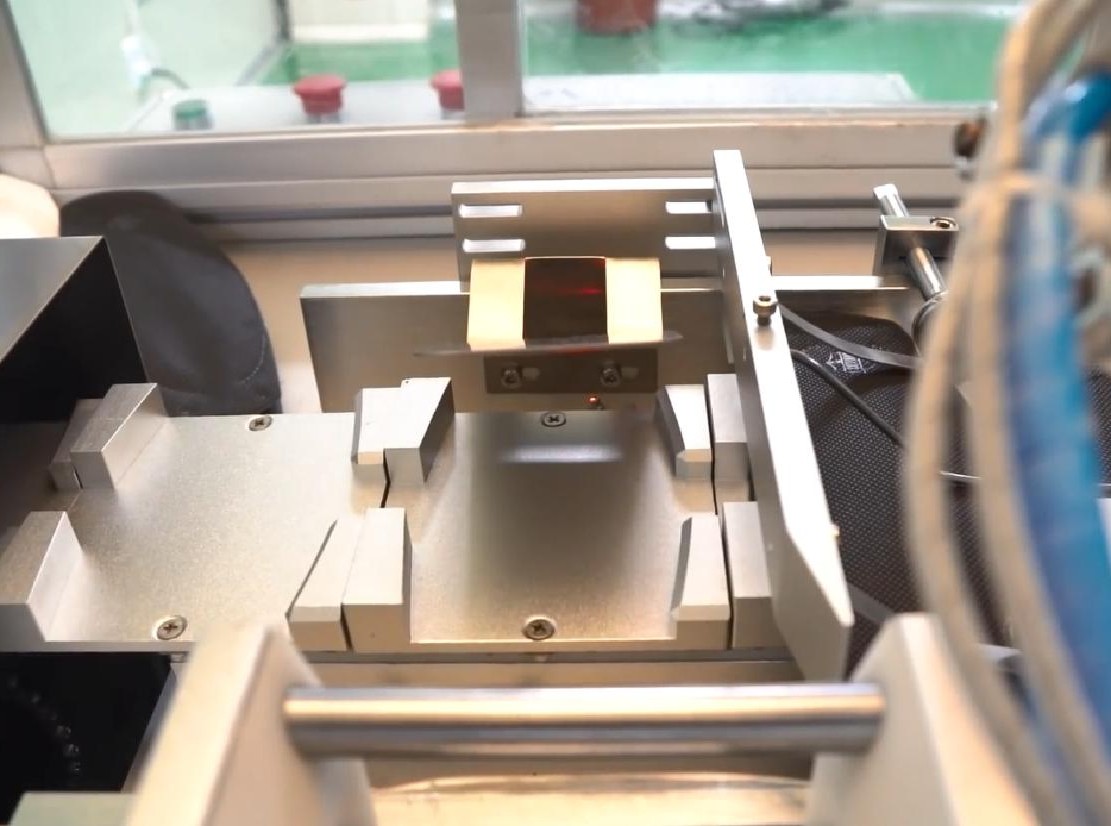

B. INDIVIDUAL PHOTOELECTRIC SENSOR FOR EACH STATION

C. PANASONIC® SERVO CONTROL FOR PROCESSING MOTION

ELECTRICAL COMPONENTS: SCHNEIDER®, OMRON® OR EQUIVALENT

PNEUMATIC COMPONENTS: AIRTAC® OR EQUIVALENT TYPE FISH

TYPE: MASK MAKING LINE

FEATURES:

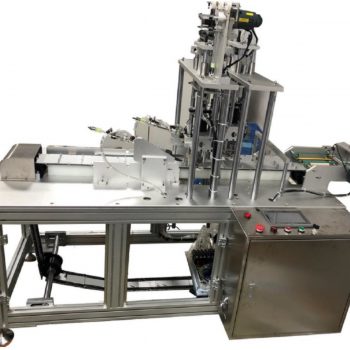

FISH TYPE MASK MAKING LINE

• COMPACT DESIGN, LESS SPACE INVESTMENT

• FULLY AUTOMATIC PRODUCTION, ONLY ONE LABOR NEEDED

• INDIVIDUAL DETECT SENSOR FOR EACH STATION, STATUS MONITOR ON TOUCH SCREEN, FAST DEBUG IF THE MACHINE FAILURE

• HIGH QUALITY ELECTRICAL COMPONENTS AND PNEUMATIC COMPONENTS

MATERIAL FEEDING SYSTEM

• ALUMINUM ALLOY FRAME, FAST TO SET UP AND ADJUST

• 1 TO 4 ROLLS MATERIAL LOADED, AND INDIVIDUAL TENSION CONTROL

• MATERIAL ROLL DIAMETER UP TO 600 mm

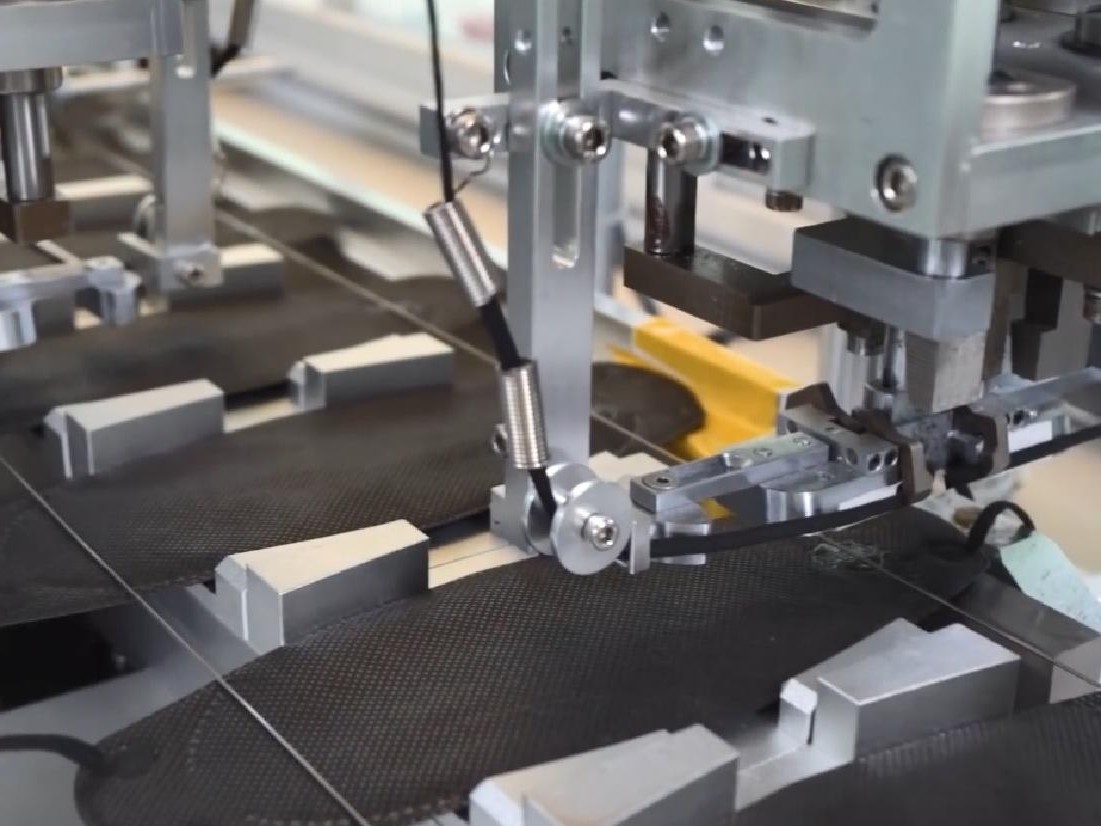

MASK FORMING MACHINE

• ROBUST ALUMINUM ALLOY FRAME, ONE – PIECE CNC STEEL WORKING TABLE

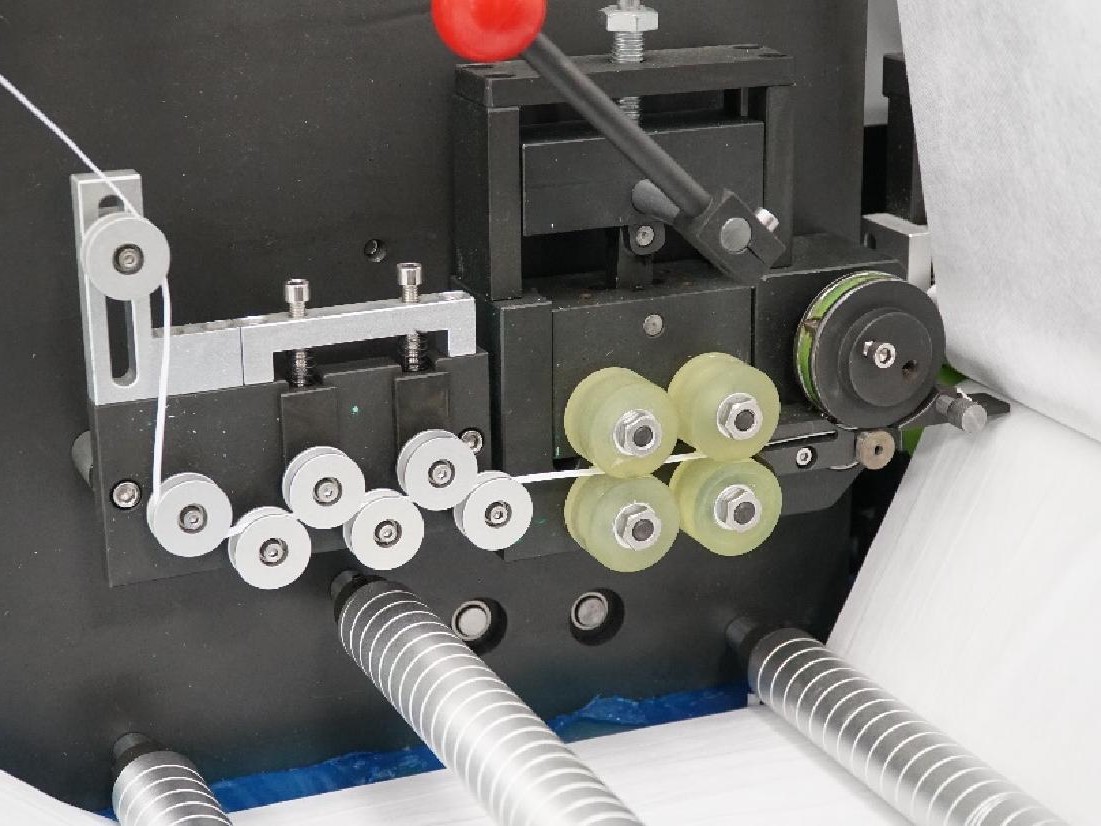

• NOSE WIRE FEEDING SYSTEM, CONSISTS OF DECOILER, FEEDING UNIT, STRAIGHTER, ENCODER, CUTTER

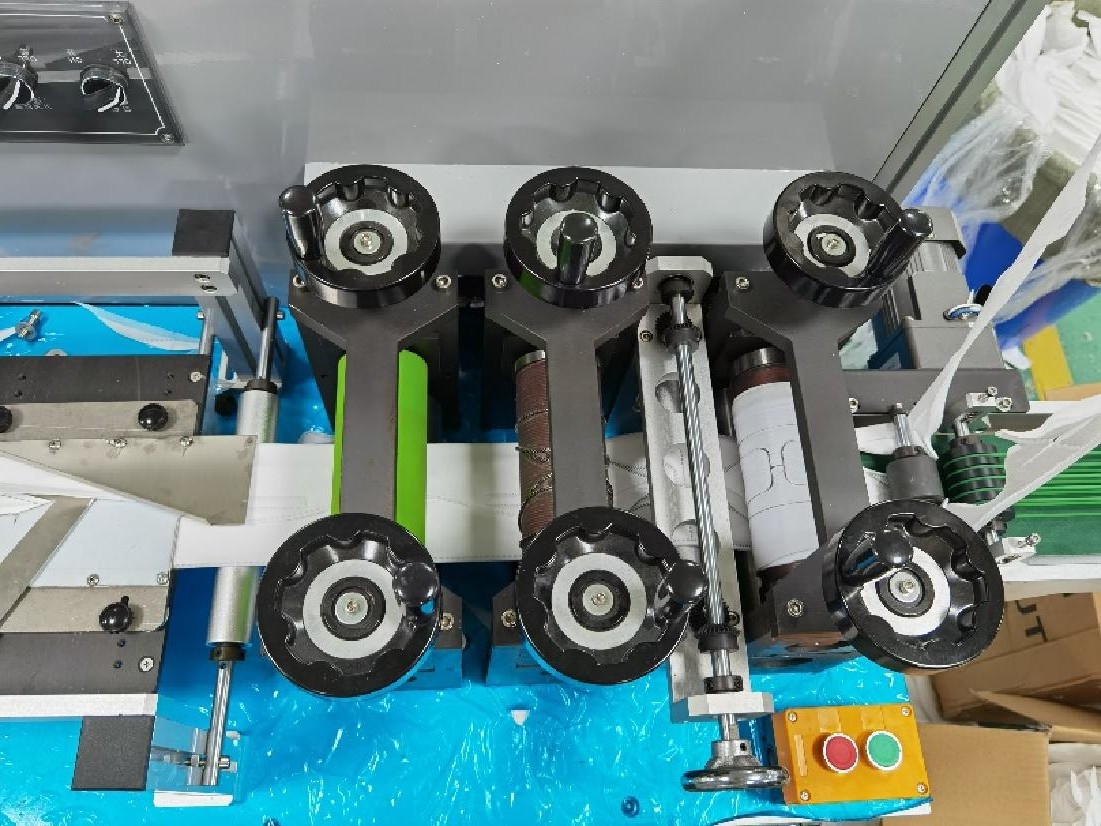

• FIRST WELDING AND CUTTING STATION, DURABLE STAINLESS STEEL MADE, SCREW ROD FOR FAST ADJUSTMENT

• FOLDING UNIT, DURABLE STAINLESS STEEL MADE, FAST TO ADJUST AND DEBUG

• SECOND WELDING AND CUTTING STATION

• ULTRASONIC STATION, EQUIPPED WITH STRONG TURBO RADIATOR

• TWO WASTE COLLECT STATION, NO LABOR NEEDED

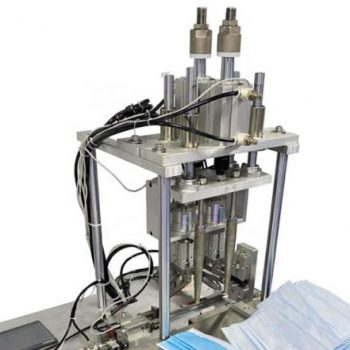

UNINTERRUPTED DOUBLE END WELDING MACHINE

• INDIVIDUAL PLC CONTROL, WITH TOUCH SCREEN OPERATING AND MONITORING

• COMPACT DESIGN, NON – COMMISSIONING ONCE SETTING UP BEFORE SHIPMENT

• SPECIFIED-SHAPE FEEDING CONVEYOR FOR FISH TYPE MASK

• DOUBLE-END UNINTERRUPTED WELDING SYSTEM

• MASK STACKING UNIT, STACKING QTY. UP TO 50 PCS, WORK WITH AUTOMATIC FEED – OUT CONVEYOR