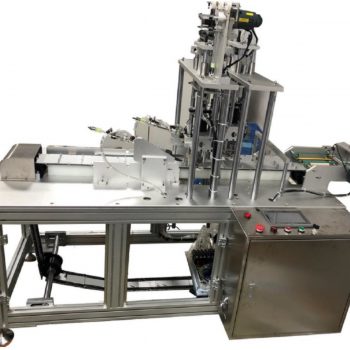

Description

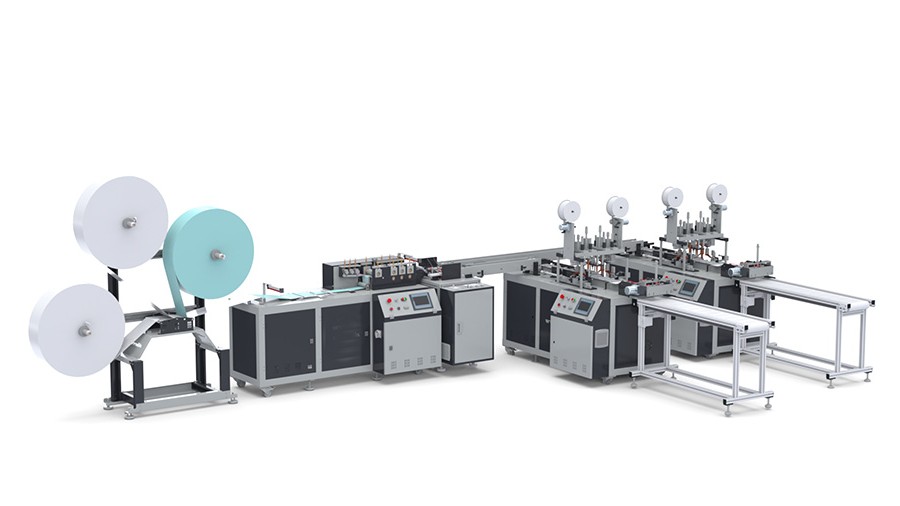

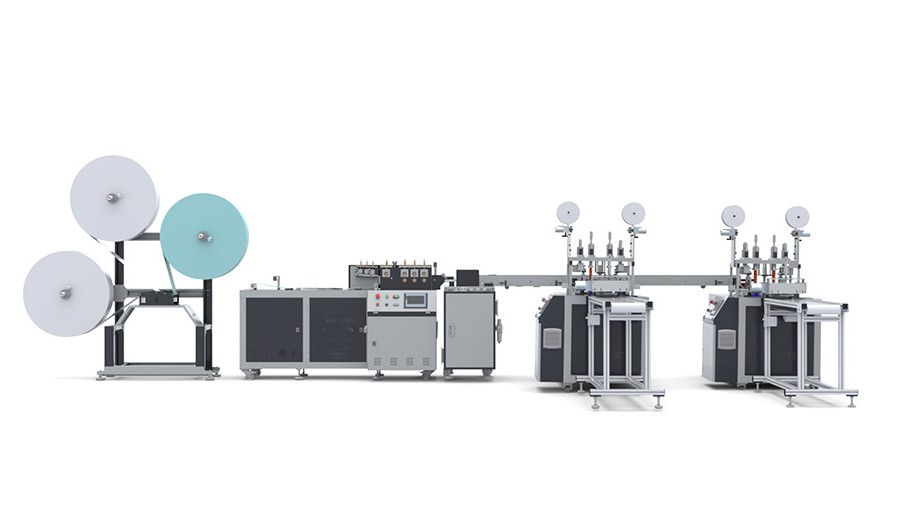

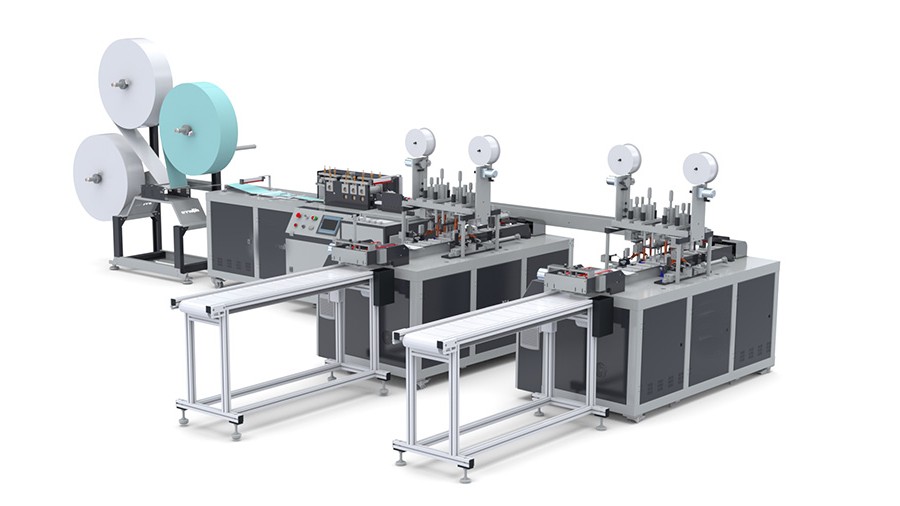

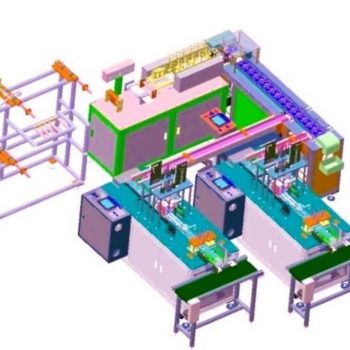

FULL Y AUTOMATIC DISPOSABLE MASK MAKING MACHINE IS DESIGNED TO PRODUCE DISPOSABLE BODIES WITH EAR LOOP ELASTICS WELDED ON AUTOMATICALLY. IT IS CAPABLE OF PRODUCING 7200 PIECES OF COMPLETE MASKS WITHOUT THE NECESSITY OF MANUAL LABOR. SENSORS INSTALLED ALL AROUND THE MACHINE ALLOWS THE USER TO KEEP TRACK OF EVERY STAGE OF THE PROCESS.

FEATURES – THE MACHINE COMES TO HALT POSITION AUTOMATICALLY ONCE IT DETECTS THE ABSENCE OF MATERIAL IN THE ENTRY POINT OF THE PRODUCTION LINE. BY RESETTING THE MACHINE FROM DISPLAY SCREEN, THE PRODUCTION MAY CONTINUE AS BEFORE.

FABRIC FEEDING UNIT – THE PRODUCTION LINE STARTS WITH A FABRIC FEEDING UNIT WHICH IS DESIGNED TO STAND DETACHED, TO INSTALL THE FABRIC ROLLS UPON WITH TENSION ADJUSTMENT MECHANISM. THIS UNIT CAN CONTAIN 3 UP TO 3 ROLLS OF NONWOVEN AND MELDBLOWN FABRIC WITH 25 CM WIDTH AND 80 CM DIAMETER.

TRANSFERRING UNIT – THE MASK BODIES THAT ARE COMPLETE ARE TRANSFERRED TO THE CONVEYOR WITH METAL BED WHICH ARE LATER CARRIED TO THE EAR LOOP WELDING SECTION WHERE THE ELASTICS ARE WELDED.

ULTRASONIC WELDING – STATE OF THE ART ULTRASONIC WELDING MECHANISM AUTOMATICALLY CALIBRATES THE CORRECT TYPE OF FREQUENCY DIGITALLY.

CONTROL PANEL – AUTOMATED WITH OMRON COMPONENTS, THE CONTROL PANEL ALLOWS THE USER TO OPERATE THE MACHINE AND CONTROL MANY FEATURES. PRODUCTION SPEED, METER COUNTER AND PIECE COUNTER ARE THE SOME OF KEY ADJUSTMENTS THAT ARE FOUND ON THE PANEL. EMERGENCY BUTTONS ARE DESIGNED TO MAINTAIN PERSONNEL SAFETY.

FABRIC FOLDING UNIT – THERE IS A FABRIC FOLDING APPARATUS MOUNTED ON THE PRESS WHERE THE FABRIC GOES THROUGH BEFORE IT IS FED INTO THE PRESS. THIS PART ALLOWS TO ADJUST THE WIDTH OF THE FOLDS AS WELL AS THE POSITIONING OF THE FABRIC.

STATIC PREVENTING WIRE – TO ELIMINATE THE SUBSTANTIAL AMOUNT OF THE STATIC ELECTRICITY GENERATED DURING THE PRODUCTION AND THE WINDING UP OF THE NONWOVEN FABRIC ROLLS DT- 4600 MASK MACHINE FEATURES 2 STATIC PREVENTING WIRES ONE OF WHICH IS IN THE FRONT AND THE SECOND ONE IS AT THE EXIT OF THE PRODUCTION LINE.

NOSE WIRING – NOSE WIRING FEEDING MECHANISM ALLOWS THE USER TO PRODUCE ADJUSTABLE CLIPS FOR THE NOSE PART OF THE MASK BODIES USING A SPECIAL REELING SYSTEM.

OPTIONS – REMOTE ACCESS MODULE – THIS FEATURE ENABLES THE MACHINE TO BE CONTROLLED OVER A MOBILE USING AN APP.

SPECIFICATIONS:

CAPACITY: 120 TO 150 PCS / Min

MAIN POWER: 11 KW (SINGLE PHASE)

VOLTAGE: 220 VOLTS AND 50/60 Hz

DIMENSIONS: 7150 X 3950 X 2100 mm

PACKAGING DIMENSIONS: 2000 X 740 X 1520 mm

2000 X 1000 X 1650 mm (2 CRATES)

2600 X 3150 X 3150 mm

1650 X 1650 X 1150 mm

GROSS WEIGHT: 1730 KG