Description

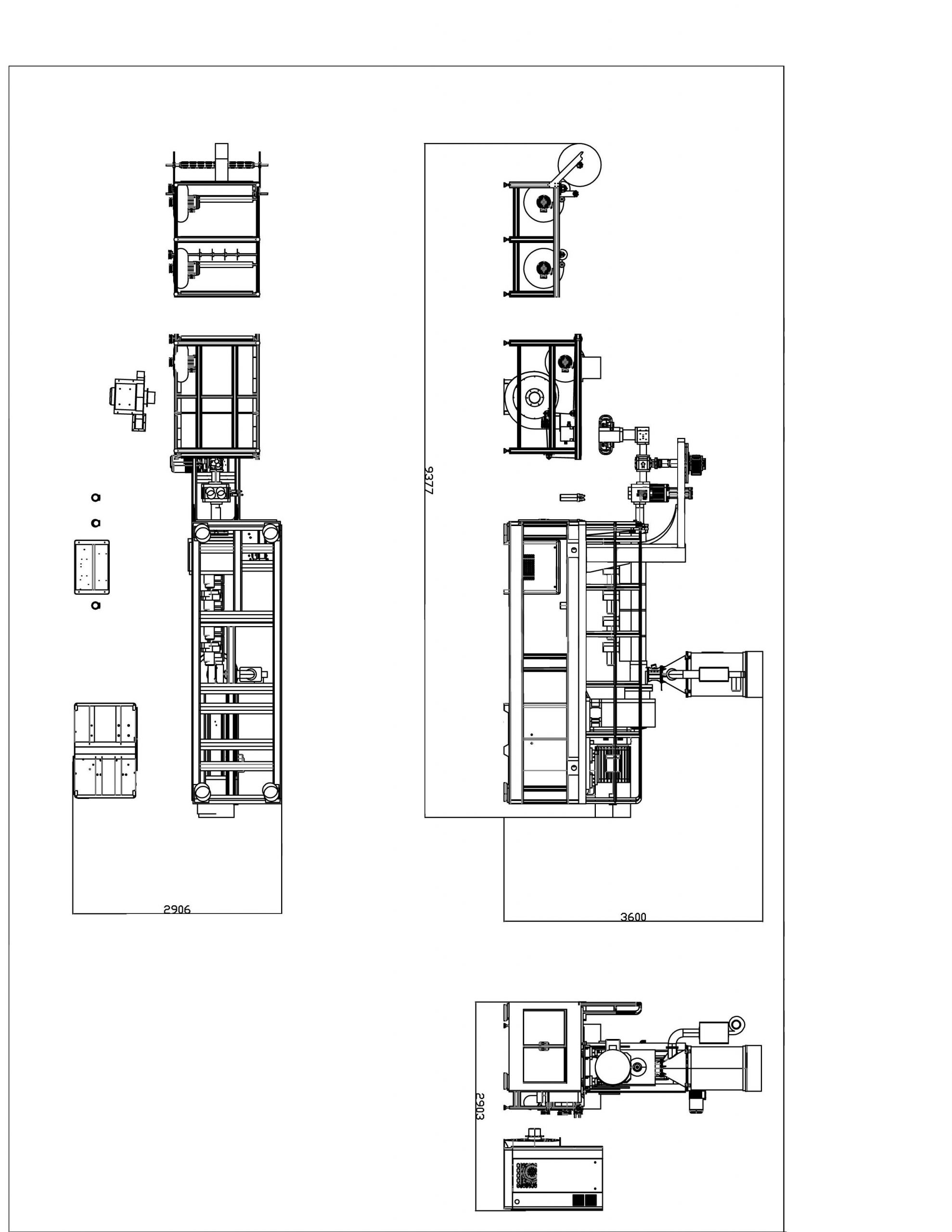

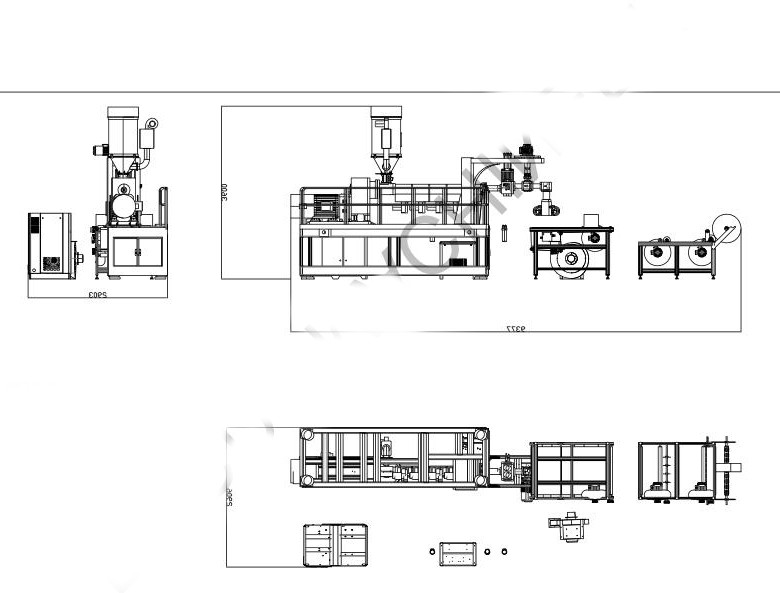

MACHINE TYPE: MELTBLOWN

WORKING WIDTH: 600mm

PRODUCTION SPEED: 15 M/min

EXTRUDER DIAMETER IN mm: 65mm

PRODUCT WEIGHT RANGE: 20 TO 100 GSM

MAX OUTPUT: 300 TO 350 KG/24 HOURS

FIBER: 2 TO 5 MICRONS

VOLTAGE: 220 VOLTS AND 50/60 Hz

SPECIFICATIONS:

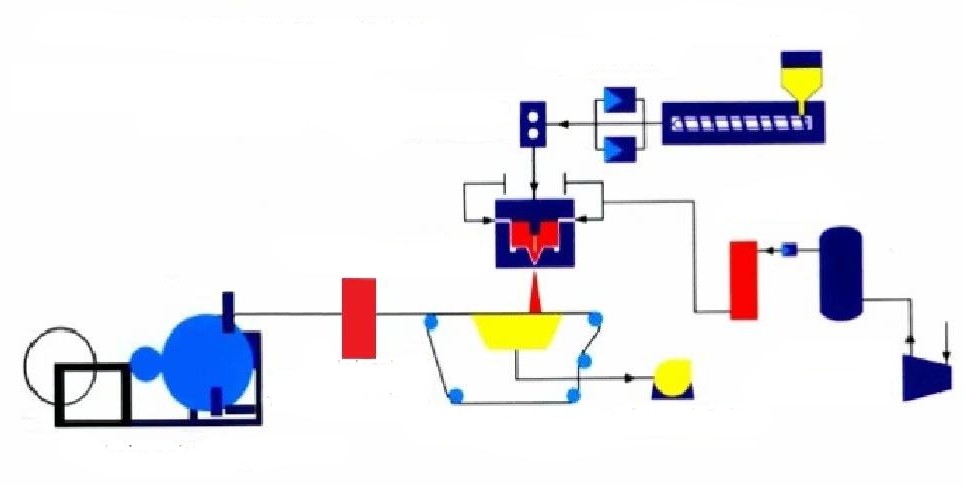

PP GRANULE MIXING MACHINE

• MACHINE MODEL: 500KGS

• MAIN MOTOR POWER: 3 KW / 4 HP

• ROTATING SPEED: 85 R/min

• MIXING TIME: 0 TO 30 min

• MOTOR POWER: 220 VOLTZ AND 50/60 Hz

PP GRANULE FEEDING MACHINE

• MACHINE MODEL: 300 G

• CONVEYOR CAPACITY: 3500 mm

• STAND WIND PRESSURE: 1300 mm / H2O

• RESERVOIR VOLUME: 7.5 L

• CONVEYOR TUBE INNER DIAMETER: 038

HOPPER DRYER FOR PP GRANULES

• CAPACITY: 50 KGS

• DESIGN TEMPERATURE: 40 ℃

• HEATING CAPACITY: 4.5 KW

• BLOWER HEAT PROTECTION MATERIAL: 135 W

• DIMENSION: 90 X 60 X 95 CM

• BASE SIZE 16 X 16 X Ф 7 CM

PP MELT – BLOWN EXTRUDER (HIGH – EFFECTIVE SCREW)

• SCREW DESIGN: SPECIAL FOR PP MELT – BLOWN

• SCREW DIAMETER: 65 mm

• SCREW L / D: 33 : 1

• SCREW LENGTH: 2145 mm

• MAIN MOTOR POWER: 22KW, 220 VOLTZ 50/60 Hz

• SCREW BARREL MATERIAL: 38CRMOALA

• NITRIDE DEPTH OF SCREW AND BARREL: 0.5 T0 0.7 mm

• SURFACE HARDNESS OF SCREW BARREL: HV 740 TO 940

• BARREL HEATING POWER: 18.5 KW

• HEATING METHOD: CERAMIC HEATING

• BARREL HEATING ZONE: 4 ZONE

• BARREL COOLING ZONE: 3 ZONES X 0.55 KW

• ROTATIONAL SPEED: 1 TO 36 R/min

• EXTRUDER SPEED ADJUST METHOD: ABB, INVERTER

• REDUCER MODEL: QT200

• GEAR TYPE: HELICAL GEARS

• GEAR MATERIAL: 20CRMNTI

• HEAT TREATMENT OF GEAR SURFACE: QUENCHING

• COOLING SYSTEM: INTERNATIONAL COOLING AND FORCED CIRCULATION COOLING

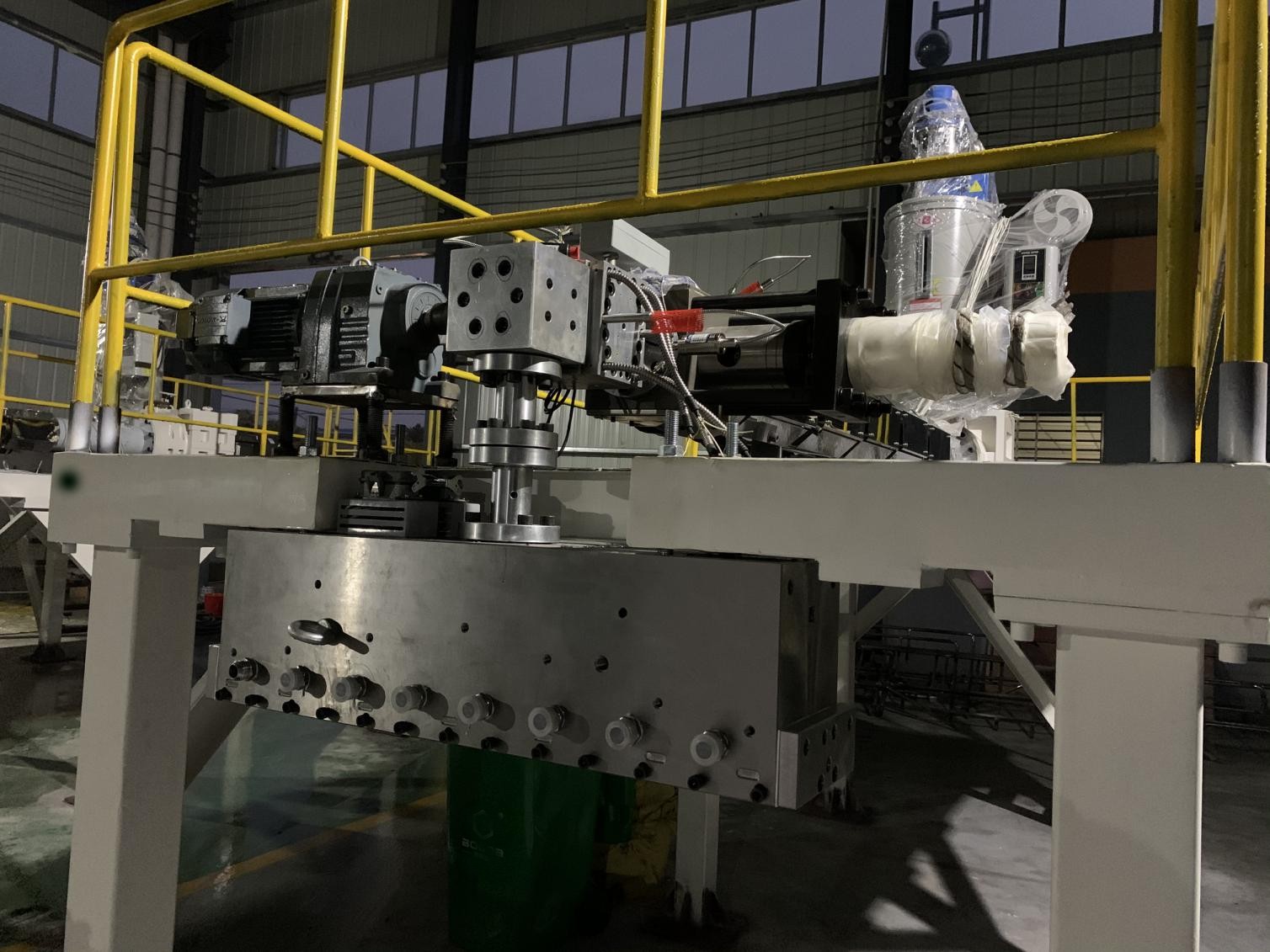

HYDRAULIC SIEVE AND STATION

• STRUCTURE: UPRIGHT TYPE, NON – STOPPING

• SCREEN CHANGING DEVICE: HYDRAULIC SYSTEM, MANUAL CONTROL

• PRESSURE SENSOR: ITALY GERFRAN BRAND

FABRIC STABLE MELTING PUMP

• SPECIFICATION: 50 CC

• MELTING CONTROL METHOD: BY INVERTER

• DRIVE MOTOR: 2.2 KW

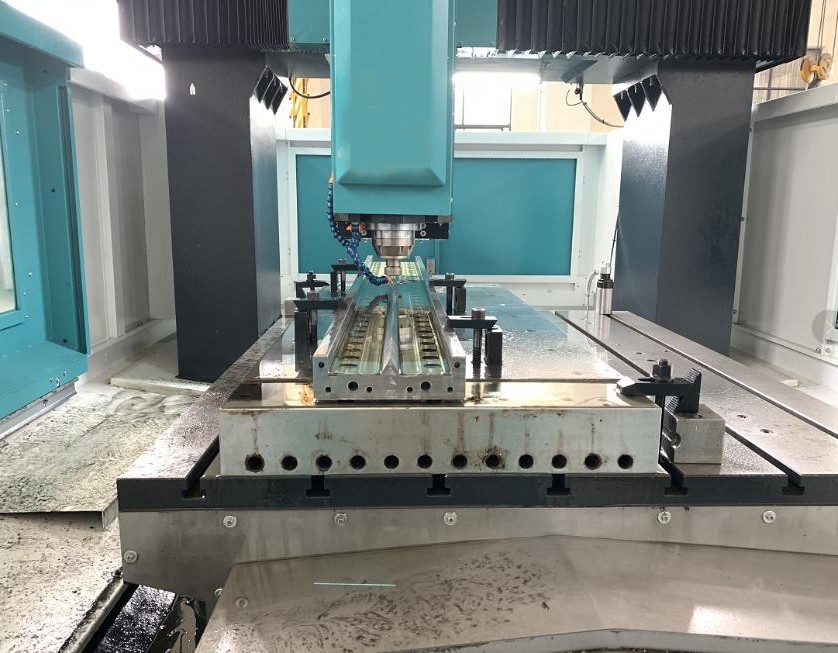

EXTRUSION MOULD (HANGER – TYPE)

• MOULD MATERIAL: S630

• DIE HEAD LENGTH: 620 mm

• HOLE WIDTH: 600 mm

• NOZZLE HOLE DIAMETER: 0.25 MM TO 0.3 mm

• SPINNERET HOLE LENGTH / DIAMETER: 10 : 1

• HEATING POWER: 12 KW

• SPINERET WITH PORE DIAMETER 0.25 MM 1 SET. THE SPINNERET CONVERTS THE MELT IN TO A THIN STREAM, WHICH IS DRAWN BY A HIGH TEMPERATURE JET STREAM TO FORM A MICROFIBER.

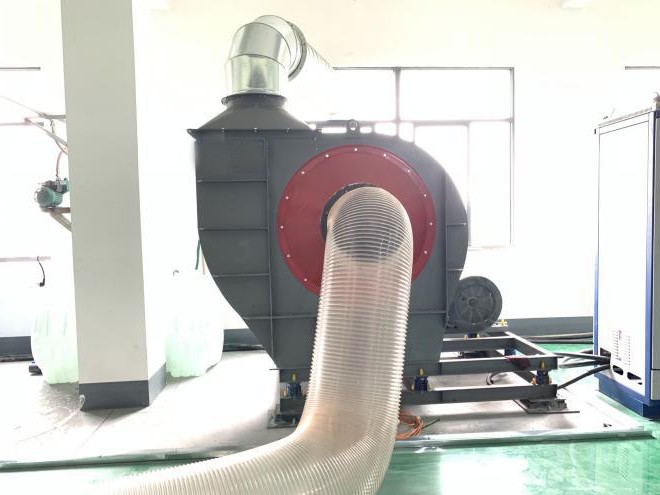

HOT – AIR SYSTEM AND CONNECTION PIPE

• PROVIDE HIGH PRESSURE AIR TO MAKE THE DRAFT AIR SPEED TO THE SCOPE OF THE TECHNICAL REQUIREMENTS BY FREQUENCY CONVERTER, ROOTS BLOWER CAN EASILY CHANGE THE OUTPUT OF THE AIR FLOW.

• INPUT FLOWING: 11 M3/min

• CONNECTION PIPES: STAINLESS STEEL

AIR HEATER AND SUCTION FAN

• HEATING POWER: 60 KW

• MATERIAL OF TANK AND TUBE: STAINLESS STEEL

• KEEP WARM TYPE: OUTPUT OF INSULATING LAYER USE STAINLESS

• SUCTION ON AIR: 35000 M3/min

• BLOWER POWER: 22 KW

• ROOTS BLOWER AIR HEATING POT: THE OUTPUT OF THE HEATED AIR, IN ORDER TO ACHIEVE THE TEMPERATURE OF THE PROCESS REQUIREMENT

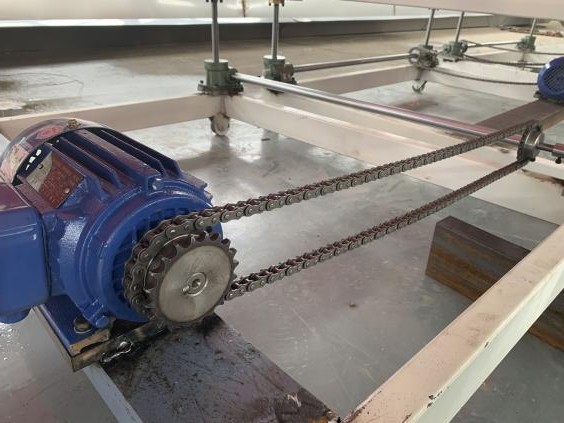

FABRIC FORMING MACHINE

• PRESSURE SENSOR: BEFORE RECEIVER BELT

• SPEED: 0 TO 50 M/min

• NET CURTAIN MATERIAL: PA

• RECEIVE NET: OVERLAPPING

• SPINNERETTE DISTANCE ADJUSTMENT: BY RAIL removing

• HEIGHT ADJUST: CAN BE ADJUST

• CONVEYOR WIDTH: 800 mm

• CONVEYOR BELT LENGTH: 4000 mm

• CONVEYOR MOTOR: 0.75 KW BY INVERTER

• BLOWER POWER: 1.1 K2 BY INVERTER

ELECTRET TREATMENT DEVICE

• INPUT VOLTAGE: 220 VOLTZ AND 50/60 Hz

• MAXIMUM OUTPUT VOLTAGE: 50 KV

• SUITABLE WIDTH: 600 mm

ONLINE CUTTING AND REWINDING

• CUTTING KNIFE MOTOR: 0.75 KW

• ROLLER MOTOR: 0.75 KW

• CONTROL METHOD: INVERTER

• AIR SHAFT: 2 PCS

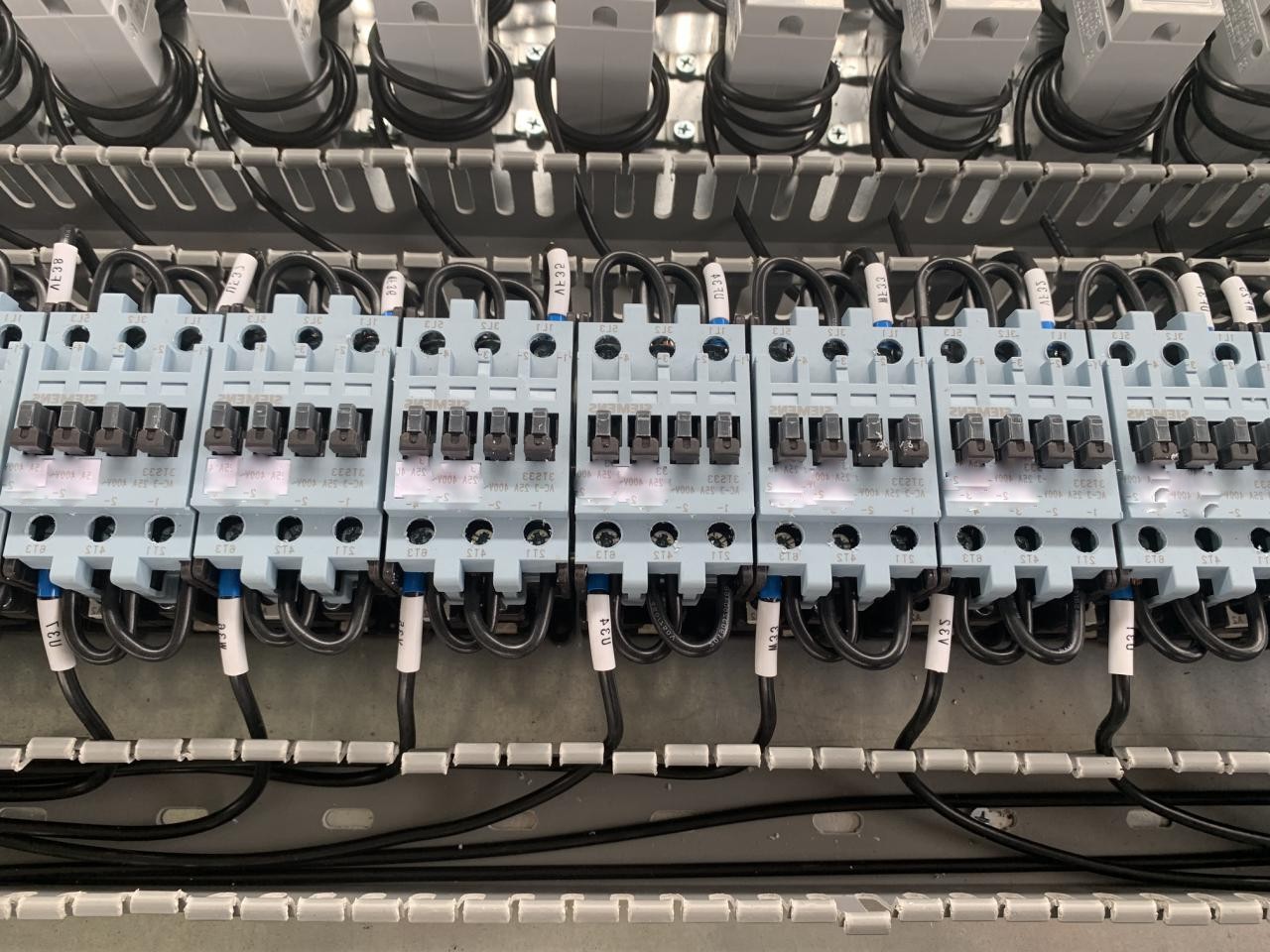

ELECTRIC CONTROL BOX

• CONTACTOR: SIEMENS

• INVERTER: ABB

• AIR SWITCH: SCNNEIDER OR EQUIVALENT

• INDICATOR GAUGE: AUTONICS

EXTRA SPINNERET PLATE

SPINNERET CLEANING SYSTEM (OVEN + ULTRASOUND)