Description

MACHINE TYPE: MELTBLOWN

WORKING WIDTH: 600mm

PRODUCTION SPEED: 13 TO 17 M/min

EXTRUDER DIAMETER IN mm: 65mm

EXTRUDER MOTOR IN KW: 22KW

PRODUCT WEIGHT RANGE: 5000 TO 6000 KGS

MELTBLOWN FABRIC THICKNESS: 25 TO 30 GSM

MAX OUTPUT: 300 TO 400 KG / 24 HOURS

DIMENSION: 15000 X 3000 X 3000 mm

WEIGHT: 5000 TO 6000 KGS

POWER (TOTAL KW): 96 KW

VOLTAGE: 220 VOLTS AND 50/60 Hz

QUANTITY OF CONTAINERS NEEDED: 1 X 40

PRODUCTION TIME: 15 DAYS

FEATURES:

PLANT SIZE

• LENGTH:MORE THAN 10000 mm

• WIDTH:MORE THAN 3000 mm

• HEIGHT:MORE THAN 35000 mm (INCLUDE HOPPER DRYER)

• RECOMMEND VACANCY SPACE 100 TO 150 M2

TEMPERATURE AND HUMIDITY

• ≤ 26℃, ≤ 60%

POWER REQUIREMENT

• 3 PHASE, 220 VOLTZ AND 50/60 Hz

FACTORY PREPARE

• ELECTRICITY, WATER, GAS, SUPPLY

POWER CONSUMPTION

• TOTAL INSTALLATION POWER: ABOUT 138 KW

• ACTUAL POWER CONSUMPTION: 96 KW

• OPERATION STAFF REQUIRED: 1 TO 2 PERSONS

SPECIFICATIONS:

MIXER

• MOTOR POWER: 2.2 KW

• MIXING THE RAW MATERIAL

VACUUM LOADER

• MOTOR POWER: 0.75 KW

• MAX LOADING DISTANCE: 4000 mm

HOPPER DRYER

• EFFECTIVE VOLUME:25 L

• HEATING POWER:2.2 KW

• FAN POWER:0.37 KW

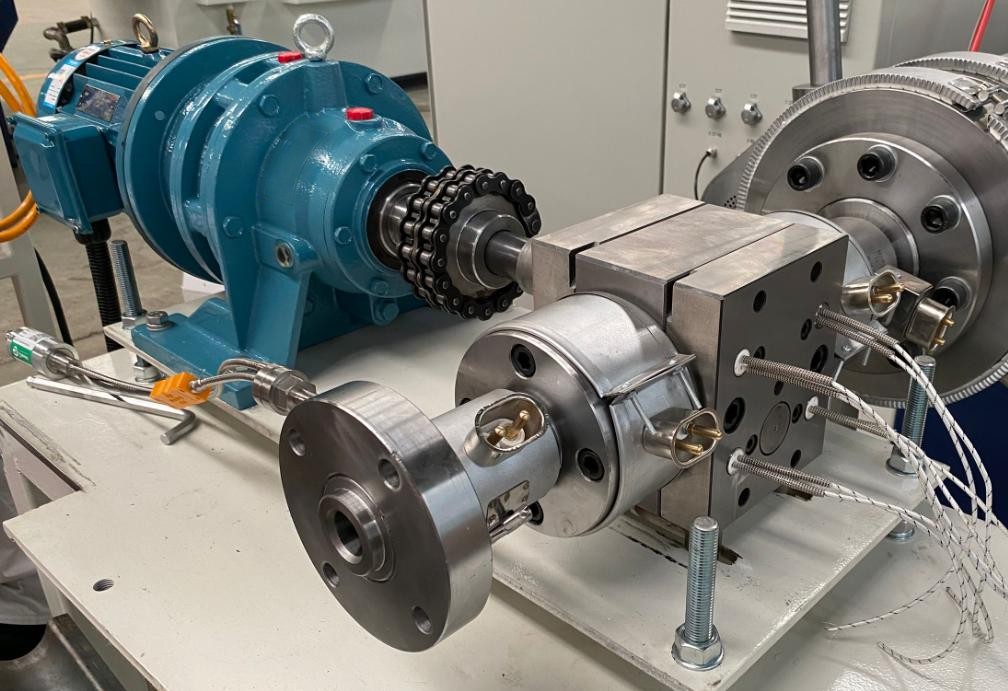

KSJ-65/30 SINGLE SCREW EXTRUDER

SCREW

• SCREW DIAMETER:65 mm

• CAPACITY: 30 TO 40 KG/H

• SCREW STRUCTURE FOR PP MATERIAL

• SCREW MATERIAL: SUPERIOR ALLOY STEEL – 38CRMOALA, NITROGEN

• TREATMENT, THICKNESS OF NITROGEN LAYER: 0.5 TO 0.7 mm, SURFACE HARDNESS: HV 740 TO 940

BARREL

• HEATING AREA: CERAMIC HEATING COIL + STAINLESS STEEL SURFACE CRUST + COOLING FAN

• COOLING EQUIPMENT: FAN BLOWING

• HEATING AREA: 5 AREAS, HEATING POWER 3 KW × 5

• FAN MOTOR POWER: 370 W × 5

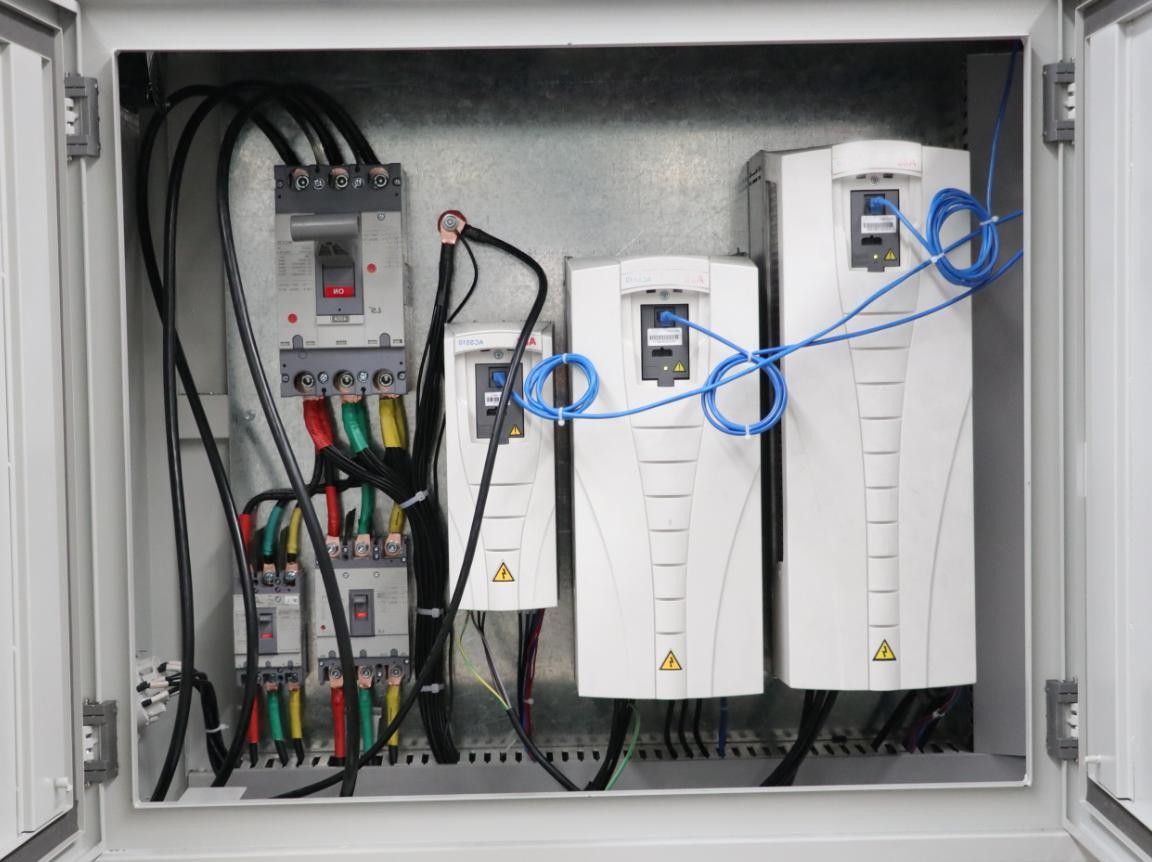

DRIVING SYSTEM

• AC MOTOR, SIEMENS BEIDE BRAND

• MAIN MOTOR POWER: 22 KW

• MAIN MOTOR SPEED CONTROL: INVERTER CONTROL

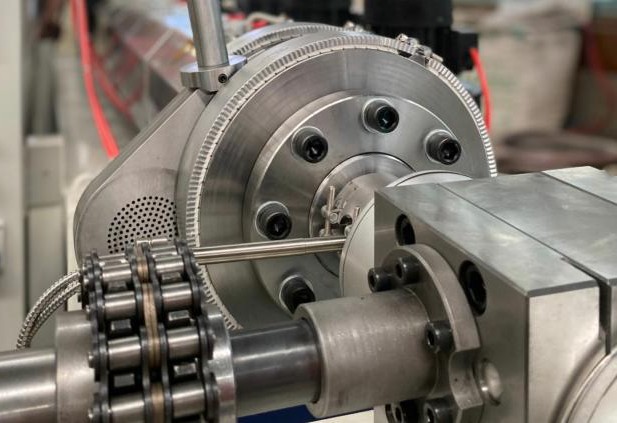

REDUCTION GEAR SYSTEM

• HIGH TORQUE REDUCER, WATER COOLING DEVICE

• CABINET MATERIAL: HT200

• GEAR FORM: BEVEL WHEEL

• GEAR MATERIAL: 20 CRMNTI

• GEAR SURFACE TREATMENT: TOOTH SURFACE QUENCHING

• SHAFT MATERIAL: 40CR

• LUBRICATION SYSTEM: PRESSURE LUBRICATION SYSTEM

FILTER

• FILTER: PLATE TYPE

• CONTROLLED BY : HYDRAULIC DEVICE

• FILTER STATION: TWO STATIONS

• POWER:2.2 KW

• A SET OF HYDRAULIC SYSTEM: INCLUDING HYDRAULIC TANK, REVERSING VALVE, HYDRAULIC CIRCUIT, OIL PUMP, OIL PUMPING MOTOR,PRESSURE SENSOR EQUIPPED WITH PRESSURE REGULATING DEVICE

• FILTER DIAMETER:80 mm

MELT PUMP

• SPEED CONTROL: INVERTER CONTROL

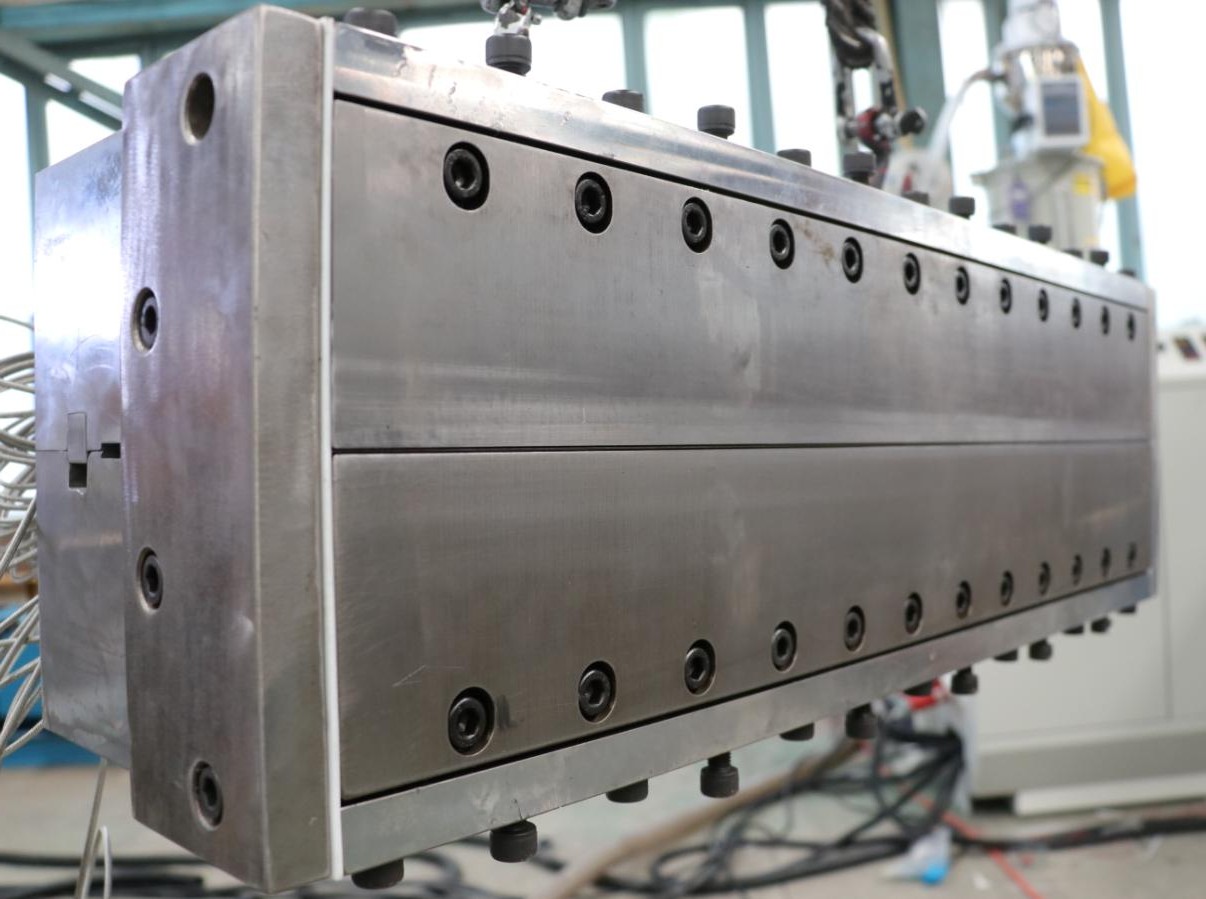

MOULD

• MOULD HEAD WIDTH: 650 mm

• MOULD HEAD: HANGER TYPE

• MELT SPINNING MOLD PLATE: 604 mm

• RAW MATERIAL OF MOULD: 1.2083 H, IMPORTED FROM GERMANY

• HOLES OF SPINNING MOLD: 0.25 mm

• DISTANCE BETWEEN HOLES: 0.6 mm

• THE TEMPLATE MATERIALS ARE ALL MADE OF ALLOY STEEL, AFTER TEMPERING TREATMENT, THE FLOW CHANNEL SURFACE IS PLATED WITH HARD CHROMIUM AND POLISHED, THE OUTER SURFACE IS DECORATED WITH CHROMIUM, AND THE HEATING METHOD IS ROD HEATING IN THE MOLD USING A HEATING TUBE

• HEATING TUBE: STAINLESS STEEL

• HEATING ZONE: 2 ZONES

• HEATING POWER: 6 KW

• AIR RUNNER: 4 PCS X 2

EXTRA SPINNING MOLD PLATE

• MELT SPINNING MOLD PLATE: 604 mm

AIR HEATER

• HIGH EFFICIENCY STAINLESS STEEL AIR HEATING TANK 1 SET

• HEATING POWER: 40 KW, ELECTRIC HEATING

• PIPE SYSTEM: 4PCS X 2, WITH FLOW VALVE

FORMING MACHINE

• FORMING NET WIDTH: 800 mm

• NET MATERIAL: NYLON

• FAN: 7.5 KW × 1 SET, INVERTER CONTROL

• AIR FLOW CONTROL: MANUAL BUTTERFLY VALVE

• REDUCER 1SET, DRIVE MOTOR: 0.75 KW

• RUNNING SPEED OF NET: INVERTER CONTROL

• INVERTER: ABB / SCHNEIDER BRAND

• CONVEYING ROLLER: STEEL ROLLER

• SURFACE TREATMENT: ROUND MILL, CHROME PLATED

• FRAME OF FORMING MACHINE: ALUMINIUM ALLOY

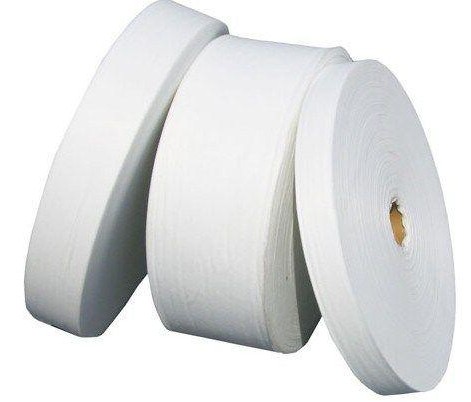

AUTOMATIC SLITTER AND COILER

• AUTOMATIC SLITTER CUT THE FABRIC IN THREE PIECES AND EDGE CUTTING

• CUTTING MOTOR: 0.55 KW

• BLADES: ALLOY BLADES

• AUTOMATIC COILER: 0.55 KW, INVERTER CONTROL

• COILER WIDTH: 800 mm

• CONVEYING ROLLER: STEEL ROLLER

• SURFACE TREATMENT: ROUND MILL, CHROME PLATED

ELECTROSTATIC ELECTRET SYSTEM

• ELECTROSTATIC ELECTRET

• ELECTRET DEVICE: 120 KV, EACH SIDE ONE PC, TOTAL 2 PCS

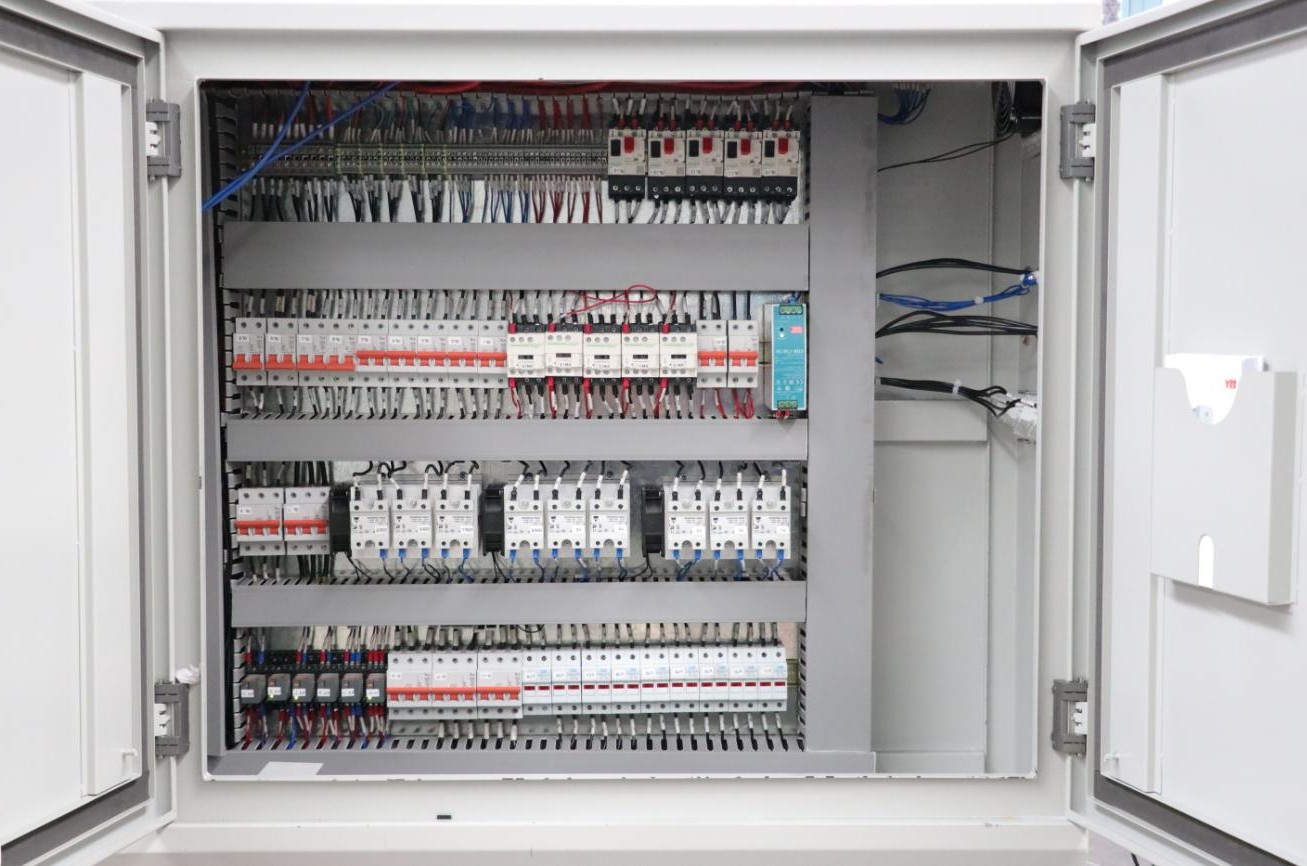

ELECTRICAL CABINET

• ELECTRIC CONTROL CABINET: 1SET

• TEMPERATURE CONTROLLER: RKC / OMRON

• INVERTER: ABB / SCHNEIDER

• CONTRACTOR: SCHNEIDER / SIEMENS

• EMERGENCY STOP DEVICE AND ALARM SYSTEM

• OVER CURRENT PROTECTION ALARM FUNCTION

• BREAKER: LS

ROOTS BLOWER

• MOTOR POWER: 45 KW

• AIR VOLUME: 20.33 M3/min

• MAX ROTATING SPEED: 1400 RPM

• SPEED CONTROL: FREQUENCY INVERTER

• FUNCTION: BLOWING FOR MOULD