Description

SPECIFICATIONS:

PP CHIPS REQUIREMENTS

• MELT INDEX: 35 TO 45 G / 10 min, FLUCTUATION RANGE OF EACH BATCH ≤1%

• MELT POINT: 166 ℃

• ASH: <0.15 TO 0.25 %

• PP COLOR MASTER BATCH AND ADDITIVE

MELT PP CHIPS REQUIREMENTS

• MELT INDEX: 1200 TO 1800 G/10 min, FLUCTUATION RANGE OF EACH BATCH ≤1%

• MELT POINT: 166 ℃

• ASH: <0.15 TO 0.25 %

• PP COLOR MASTER BATCH AND ADDITIVE

PRODUCT WIDTH: 3200 mm

MELT FILAMENT DENIER: 2 TO 5 MICRON

OUTPUT: ABOUT 14000 TON / 8000 HOURS (BASED ON 45 GSM)

WEIGHT RANGE: 15 TO 70 G / M2

MAXIMUM DIAMETER OF FABRIC PER ROLL: 1500 mm

DESIGN SPEED: <=450 M/min

RUNNING SPEED: <=400 M/min

SIZE OF MACHINE: 65000 X 24000 mm (INCLUDING AIR BLOWER ROOM) 65000 mm X 15000 mm (AIR BLOWER NOT INCLUDED)

FORE – SPINNING EQUIPMENT SIZE: 30000 X 12000 X 11000 mm

BACK SPINNING EQUIPMENT SIZE: 35000 X 8000 X 4500 mm

THE MAIN STRUCTURE OF THE EQUIPMENT:

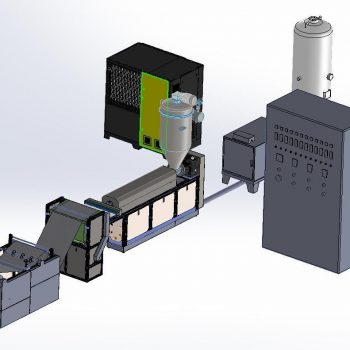

RIM CHARGE AUXILIARY SCREW AND RECYCLING UNIT

USAGE: RECYCLE THE RIM

RECYCLING SCREW USE THE ALTERNATING FREQUENCY CONVERTER

• SCREW DIAMETER: Φ 105

• SCREW HEATING ZONE NUMBER: 4 ZONES

170 MODEL SCREW EXTRUDER

USAGE: TO MIX PP, AND ADDITIVES AS COLOR MASTER BATCH, ANTIOXIDANT, FIRE RETARDANT WITH CERTAIN RATIO

MAIN TECHNICAL PARAMETER:

• SCREW SIZE: Φ 170 x 2, MAXIMUM FEEDING ABILITY: 630 KG / H × 2

• SPEED: 60 R/min

• HEATING ZONE: 7 ZONES

• AC MOTOR

SET UP HIGH LEVEL AND LOW-LEVEL ALARM DEVICE, AUTO CONTROL FEEDING DEVICE. ELECTRICAL

MOTOR OF SCREW IN MIXING DEVICE IS FREQUENCY CONVERTING.

SCREW SPINNING MACHINE

USAGE: THE PP FUSANT GO THROUGH FILTER, FUSANT PIPE, AND METERING PUMP TRANSPORT THE FUSANT INTO SPINNING CONTAINER AND FIBER COMES OUT FROM SPINNERET.

SPECIFICATIONS:

OUTPUT: ABOUT: 14000 T / YEAR

• FIBER DENIER: 1.8 TO 2.3 DENIER

• WEIGHT RANGE: 15 TO 70 GSM

SWITCHED MELT FILTER

• FILTER RATINGS: 250

• FILTER AREA: 5.5 SQUARE METER

METERING PUMP AND TRANSMISSION UNIT

• PUMP OFFERING QUANTITY: 300 CC × 2

SPINNING CONTAINER

• HEATING PATTERN: OIL HEATING

FUSANT PIPE

• HEATING PATTERN: OIL HEATING

SLOT SUCTION DEVICE

• AIR PRESSURE: 1300 PA FLUX: 844 M3 / H

SPINNING COMPONENT

• HOLE DIAMETER: 0.42 mm

• L/D: 1:4

• MATERIAL: SUS431

STRETCHING DEVICE (NEW MODEL)

USAGE: STRETCHING AND COOLING THE FIBER

MAIN TECHNICAL PARAMETER: WORKING WIDTH: 3200 mm

DEVICE COMPONENTS:

• THE DEVICE CONTAINS QUENCHING CHAMBER, UP STRETCHING CHANNEL, DOWN STRETCHING CHANNEL, DIFFUSE WINDER TUNNEL ETC. USING DOUBLE – SIDE SYMMETRY WIND TO COOL FIBER

• STRETCHING SLIT IN DOWN STRETCHING DEVICE CAN ADJUST ACCORDING TO CRAFT REQUIREMENTS. ADJUST SYSTEM TAKES TORQUE MOTOR DRIVE

• THE NEW TYPE OF UPPER AND LOWER STRETCHER CHANGES THE CHARACTERISTICS OF THE TRADITIONAL UPPER AND MIDDLE STRETCHER WHICH CANNOT BE ADJUSTED, MAKING THE EQUIPMENT MORE REGULATED TO THE AIR VOLUME AND THE WIDTH OF THE NARROW SEAM, AND ENSURING THE HIGHER REQUIREMENTS OF THE CUSTOMERS FOR THE SILKY DEGREE. THE HEIGHT OF THE STRETCHER IS LENGTHENED, SO THAT THE NON – WOVEN FIBER CAN BE FINER, SO THAT THE NON – WOVEN FABRIC IS MORE EVEN AND THE TENSION IS STRONGER

WEB FORMING MACHINE

USAGE: OFFER CARRIER FOR FIBER AFTER STRETCHING.

MAIN TECHNICAL PARAMETER:

• AIR SUCTION QUANTITY: 57000 M3 / H

• DESIGN SPEED: <= 450 M/min

• NORMAL RUNNING SPEED: <=400 M/min

• WEB – LAYING APRON: VENTING QUALITY: 7000 TO 10000 M3 / H.M2

DEVICE COMPONENTS

WEB – LAYING APRON TRANSMISSION DEVICE

AIR SUCTION CHANNEL

SEALING DEVICE

POSITION CORRECTING SET

TENSION DEVICE

RACK DEVICE

MOTOR DRIVE ROLLER