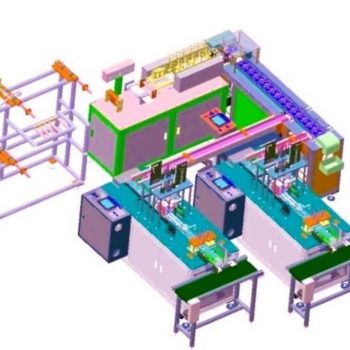

Description

MACHINE WILL COMPLETE THE WHOLE PRODUCTION PROCESS FROM RAW MATERIAL ROLL TO FINISHED PRODUCT OF THE MASK. THE EQUIPMENT INCORPORATES ULTRASONIC WELDING MODE, SANITATION AND ENVIRONMENTAL PROTECTION.

SPECIFICATIONS:

MACHINE SIZE: 5000 X 2500 X 1900 mm

NET WEIGHT: <= 2000 KGS GROUND BEARING ≤200 KG/M2

WORKING POWER: 220 VOLTS AND 50/60 Hz

COMPRESSED AIR: 0.5 TO 0.7 MPA

USAGE FLOW: 150 L/min

USE ENVIRONMENT: TEMPERATURE 1O TO 35℃

HUMIDITY: 5 TO 55% HR, NO COMBUSTIBLE OR CORROSIVE GAS OR DUST

NORMAL PRODUCTION: 60 TO 90 PCS/min

FEATURES

• INCORPORATING ULTRASONIC WELDING TECHNOLOGY, SANITARY AND ENVIRONMENTAL – FRIENDLY

• WHOLE PRODUCTION LINE IS AUTOMATIC FROM FEEDING, NOSE STRAP INSERTING, EDGE SEALING AND CUTTING FINISHED PRODUCTS

• THE FRAME STRUCTURE IS MADE OF ALUMINUM ALLOY AND THE KEY PARTS ARE MADE OF STAINLESS STEEL.

• COMPUTER PLC PROGRAMMING CONTROL, STEP OR SERVO DRIVE, PARTIAL PNEUMATIC DRIVE, HIGH STABILITY, LOW FAILURE RATE, HIGH EFFICIENCY

• FEEDING, WELDING AND BINDING OF EARBELT ARE DRIVEN BY STEP OR SERVO MOTOR

• THE TENSION OF THE RAW MATERIALS HAS AUTOMATIC CONTROL TO ENSURE THE TENSION BALANCE OF RAW MATERIALS

• PHOTOELECTRIC (OPTICAL FIBER) DETECTION OF RAW MATERIALS TO AVOID MISTAKES AND REDUCE MATERIAL WASTE